+86-13516964051

+86-13516964051

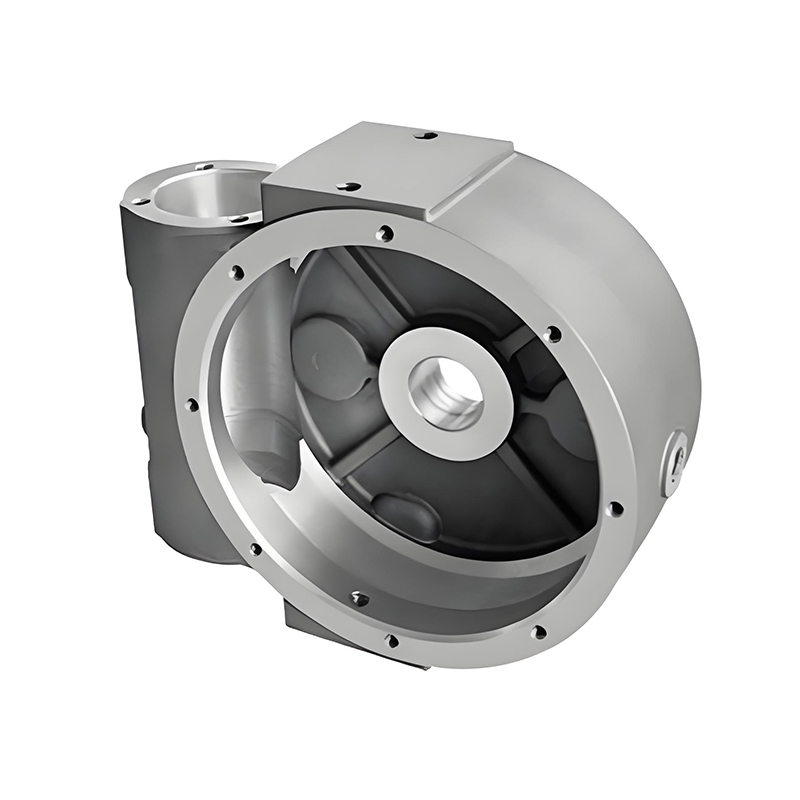

Zinc high pressure die casting

description1

01

Principle of Zinc Alloy High Pressure Die Casting

High pressure filling: In the process of die casting, the zinc alloy liquid is filled into the mold cavity at a high speed under the action of high pressure. Commonly used pressures range from a few mpa to tens of mpa, and filling speeds are about 16-80 m/s.

Rapid solidification: After filling is completed, the alloy quickly solidifies under pressure to form the casting. This process is usually completed in a very short time, filling time is only 0.01-0.2 seconds.

Process parameters: In the process of die casting, the process parameters such as pressure, speed, temperature and time have important effects on the quality of the casting. The correct selection and adjustment of these parameters, such as pressure, temperature and time, is the key to obtaining high-quality castings.

02

Characteristics and advantages

High production efficiency: because of the fast filling speed and short solidification time, the die casting process has a high production efficiency.

Casting quality: die-casting parts have high tolerance levels, good surface roughness and high mechanical strength, usually can save a lot of mechanical processing processes and equipment.

Wide range of application: suitable for the manufacture of various complex shapes of parts, especially thin-walled parts, and the casting surface is smooth.

Material properties: zinc alloy has the advantages of low melting point, good casting performance and excellent mechanical properties, suitable for die casting molding.

03

application area

Zinc alloy high pressure die casting is widely used in a variety of fields, including but not limited to:

● Auto parts: such as engine parts, body structure parts, etc.

● Electronic product shell: such as mobile phone shell, laptop shell, etc.

● Medical instruments: such as surgical instruments, medical equipment enclosures, etc.

● Other industrial products: such as home appliance shell, lighting accessories, etc.