+86-13516964051

+86-13516964051 Comprehensive Guide to Pressure Die Casting Process for OEM Manufacturers

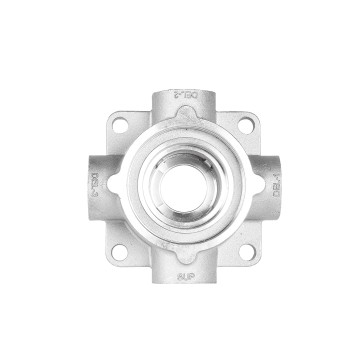

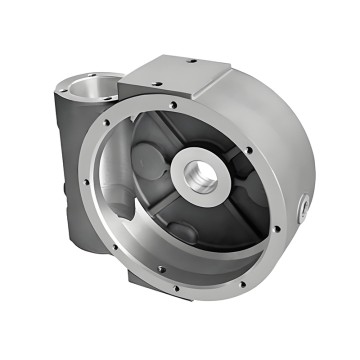

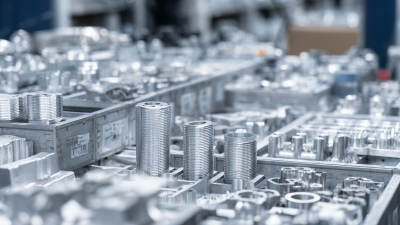

At Yongkang Hantai Industry And Trade Co., Ltd., we specialize in the Pressure Die Casting process, ensuring the creation of high-quality metal components. As a prominent manufacturer and supplier, we prioritize precision to meet the demands of various industries. Our advanced techniques yield intricate designs with exceptional surface finishes, adhering to stringent standards. Each stage of our casting process is meticulously managed, resulting in minimized waste and enhanced efficiency. By partnering with us, you gain a dedicated collaborator focused on delivering durable, high-quality products customized to your requirements. Our commitment to innovation and customer satisfaction ensures we provide reliable and effective solutions for your business. Rely on us for superior pressure die casting that brings your projects to fruition.How To find Pressure Die Casting Process Manufacturers You Can Rely On Factory-Direct Excellence

Finding reliable manufacturers for pressure die casting processes can significantly impact the quality and consistency of your automotive parts and components. With countless options available in the global market, it's essential to identify suppliers who prioritize technological innovation and quality improvement. At Yongkang Hantai Industry & Trade Co., Ltd., established in 1997, our commitment to excellence in manufacturing has driven us to become a trusted partner for businesses seeking high-quality solutions. When sourcing manufacturers, consider their experience and technological capabilities. Look for companies that have a proven track record in the automotive industry. Yongkang Hantai has continuously invested in advanced technologies to enhance production efficiency and ensure top-notch quality in every part we deliver. Our focus on quality control processes guarantees that our products meet stringent industry standards and customer specifications, providing you with peace of mind. In addition to technological prowess, it's vital to evaluate the manufacturer's communication and customer service. A reliable partner should be responsive to your needs, understanding the complexities of the automotive supply chain. At Yongkang Hantai, we pride ourselves on our customer-centric approach, ensuring seamless collaboration and support throughout the procurement process. Partnering with manufacturers who embody these qualities will not only enhance your production quality but also foster a long-term relationship built on trust and excellence.

How To Find Pressure Die Casting Process Manufacturers You Can Rely On Factory-Direct Excellence

| Manufacturer Location | Production Capacity (Tons/Month) | Quality Certifications | Lead Time (Weeks) | Customer Rating (1-5) |

|---|---|---|---|---|

| USA | 150 | ISO 9001, IATF 16949 | 6 | 4.5 |

| Germany | 100 | ISO 9001, EN 15552 | 8 | 4.8 |

| China | 200 | ISO 9001, RoHS | 4 | 4.0 |

| India | 120 | ISO 9001, OHSAS 18001 | 5 | 4.2 |

| Italy | 80 | ISO 9001, CE | 7 | 4.6 |

Why Invest In Pressure Die Casting Process Where Service Meets Innovation Service

N

Noah Clark

Impressive product quality! The after-sales service team went above and beyond to assist me, showcasing their professionalism. An excellent choice!

01 June 2025

J

Jackson Allen

The item exceeded all my expectations in quality. The support team was professional, friendly, and incredibly helpful throughout the process.

21 June 2025

J

Julian Harris

I am very pleased with this purchase! The customer service team was friendly, knowledgeable, and very helpful.

15 June 2025

C

Cora Nguyen

Amazing craftsmanship and quality! Their customer service was professional and quick to respond to my needs.

30 June 2025

N

Natalie Brown

This product is outstanding! The customer service was refreshingly knowledgeable and very professional.

23 May 2025

H

Hazel Mitchell

Love the durability and quality of this item! Customer service was very professional and knowledgeable, which I appreciated.

24 May 2025