+86-13516964051

+86-13516964051 Practice and Strategy of Reducing Carbon Emissions in High-Pressure Casting Using Recycled Aluminum

Practice and Strategy of Reducing Carbon Emissions in High-Pressure Casting Using Recycled Aluminum

Introduction

Against the backdrop of increasing global attention to environmental protection and sustainable development, reducing carbon emissions has become an important task for all walks of life. As a widely used metal processing process, aluminum alloy high-pressure casting has attracted much attention for its carbon emissions. The application of recycled aluminum has brought new opportunities to this industry. This article will explore in depth the application of recycled aluminum in high-pressure casting and analyze how it can effectively reduce carbon emissions, providing a more sustainable option for international wholesale buyers.

Definition and Advantages of Recycled Aluminum

Definition

Recycled aluminum refers to aluminum materials produced by recycling and reprocessing aluminum waste (including scraps in the production process and waste aluminum products after use). It has the same physical and chemical properties as primary aluminum, but the energy consumption and carbon emissions in the production process are significantly reduced.

Advantages

Low energy consumption: The energy consumption of producing recycled aluminum is only 5% of that of primary aluminum. This is because the production process of recycled aluminum focuses on the melting and purification of waste aluminum, without the need to undergo a complex electrolysis process like primary aluminum production.

Low carbon emissions: Compared with the production of the same amount of primary aluminum, the production of 1 ton of recycled aluminum only produces 0.5 tons of carbon dioxide emissions. In the production process of primary aluminum, the carbon dioxide emissions per ton of aluminum are as high as 15,400 kg.

Resource conservation: The production of recycled aluminum can effectively reduce the exploitation of natural resources and reduce the emission of solid waste.

Application of recycled aluminum in high-pressure casting

Introduction to high-pressure Casting Process

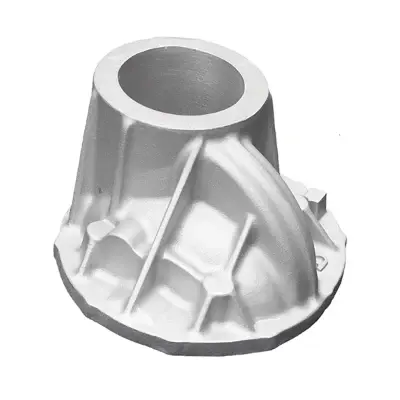

High-pressure casting is a casting process in which molten metal is quickly injected into the mold cavity under high pressure and solidified under pressure. It is widely used in the fields of automobiles, aerospace, electronics, etc., and is favored because it can produce parts with complex structures and precise dimensions.

Use of recycled aluminum

Recycled aluminum can be used as the main raw material for high-pressure casting. Through reasonable proportioning and processing, it can meet the performance requirements of high-pressure casting for aluminum alloys. Its application not only reduces production costs, but also significantly reduces carbon emissions.

Mechanism of recycled aluminum to reduce carbon emissions

Reduction of energy consumption

In the process of high-pressure casting, the use of recycled aluminum can significantly reduce energy consumption. The melting temperature of recycled aluminum is lower, and the preheating and melting process of scrap aluminum is more efficient. For example, the use of advanced double-chamber furnace smelting technology can reduce the direct contact between scrap aluminum and natural gas and the outside air, thereby reducing aluminum burnout and natural gas consumption. Compared with traditional processes, this technology can reduce natural gas consumption by about 15 cubic meters per ton.

Reduction of waste gas emissions

The waste gas generated during the production of recycled aluminum is relatively small, and modern smelting technologies, such as the liquefaction and separation of scrap aluminum, can minimize air pollution. This technology combines the pretreatment of scrap aluminum and re-casting, which greatly improves the recovery rate of net metal and reduces waste gas emissions.

Reduction of waste slag emissions

In the production process of recycled aluminum, the generation of waste slag can be reduced through effective pretreatment and smelting processes. For example, the use of a fully automatic paint stripping furnace to harmlessly treat the surface coating in the raw material greatly reduces the secondary reaction in the process of aluminum slag generation. This treatment method can reduce the burnout rate by 4% to 6%, thereby improving the utilization rate of aluminum.

Carbon emission accounting for recycled aluminum High Pressure Casting

System boundary

The system boundary of carbon emission accounting for recycled aluminum high pressure casting includes the acquisition of raw and auxiliary materials, production process, packaging and storage. Specifically:

Raw and auxiliary material acquisition stage: including the acquisition process of raw and auxiliary materials such as aluminum ingots for remelting, intermediate alloys, flux, etc.

Production stage: the entire process from the entry of raw materials into the factory to the storage of finished products, including pretreatment, smelting, casting and other links.

Packaging and storage stage: including the packaging, storage and transportation of ingots.

Accounting method

Carbon emission accounting usually adopts the emission factor method, that is, carbon emissions are calculated by multiplying activity data by emission factors. For example, carbon emissions generated by the combustion of fossil fuels can be calculated by fuel consumption and corresponding emission factors.

Data source

Data sources include direct measurements, data provided by suppliers, and industry averages. In the accounting process, directly measured data should be used first to ensure the accuracy of the accounting results.

Optimization strategy for high-pressure casting of recycled aluminum

Improve the recycling rate of recycled aluminum

The recycling rate of recycled aluminum can be improved through advanced pretreatment technology and smelting process. For example, eddy current separator is used to remove impurities, and double-chamber furnace smelting technology is used to reduce burning loss. These measures not only improve the utilization rate of aluminum, but also reduce energy consumption and carbon emissions.

Optimize smelting process

The use of efficient smelting equipment and technologies, such as double-chamber reverberatory furnace and liquefaction separation device, can significantly reduce energy consumption and waste gas emissions. These equipment reduces the burning loss and energy waste of waste aluminum by optimizing the smelting process.

Environmental protection measures

In the process of high-pressure casting of recycled aluminum, complete waste gas treatment equipment should be equipped to ensure that the waste gas meets the emission standards. In addition, by optimizing the production process and reducing the generation of waste slag, carbon emissions can also be reduced.