+86-13516964051

+86-13516964051 Melting Temperature: The Core Code That Determines the Quality of Aluminum Alloy Castings

Melting Temperature: The Core Code That Determines the Quality of Aluminum Alloy Castings

In the aluminum alloy casting production chain, the melting process is like the heart of alchemy, and melting temperature is the key to mastering this art. Whether novice or experienced, they all know that even subtle differences in temperature control can turn a casting from "qualified" to "scrap." This article will delve into how melting temperature fundamentally affects the chemical composition stability, internal microstructure quality, mechanical properties, and production efficiency of aluminum alloy castings, providing professional reference for companies to optimize production processes and enhance product competitiveness.

I. The "Double Bottom Line" of Melting Temperature: Both Too Low and Too High Can Be Hidden Dangers

Aluminum alloy melting is not a matter of "the higher the temperature, the better" or "just melting it." Instead, it must be strictly controlled within a specific range. The upper and lower limits of this range correspond to different quality risks. Once this "double bottom line" is exceeded, casting defects will follow.

1. Too Low a Temperature: Chain Defects Caused by "Incomplete Melt"

When the melting temperature is below the minimum acceptable melting temperature for an alloy, the molten aluminum cannot fully melt and flow, leading to a series of irreversible defects:

Chemical Composition Inhomogeneity: At low temperatures, alloying elements such as silicon, magnesium, and copper in the alloy are difficult to evenly disperse, easily causing "segregation." For example, in ADC12 aluminum alloy, if the temperature is insufficient, silicon particles will aggregate to form coarse, blocky structures, leading to localized imbalances in casting properties and potentially increased tool wear during subsequent processing.

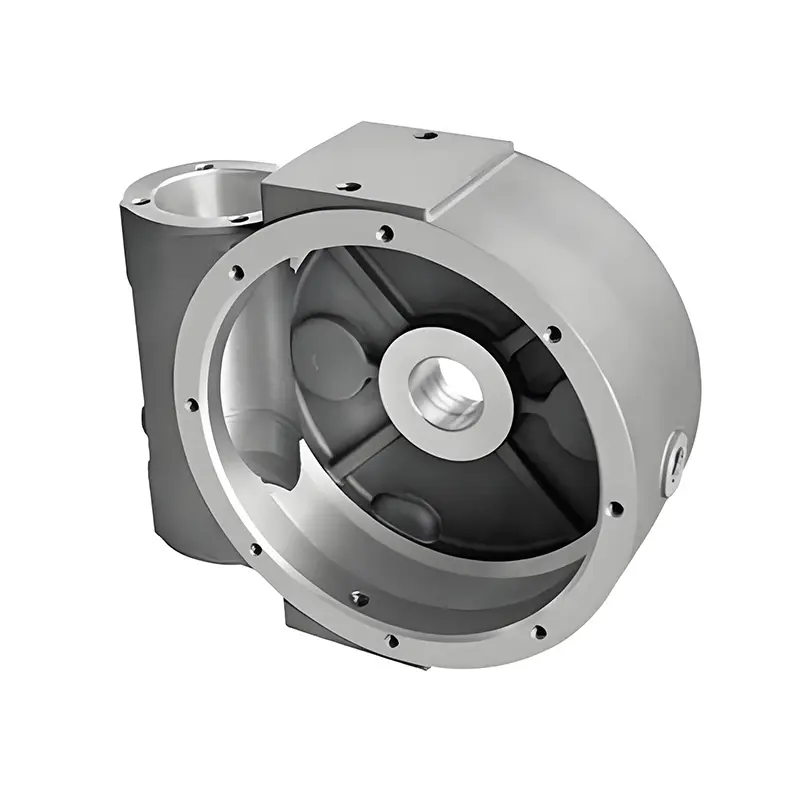

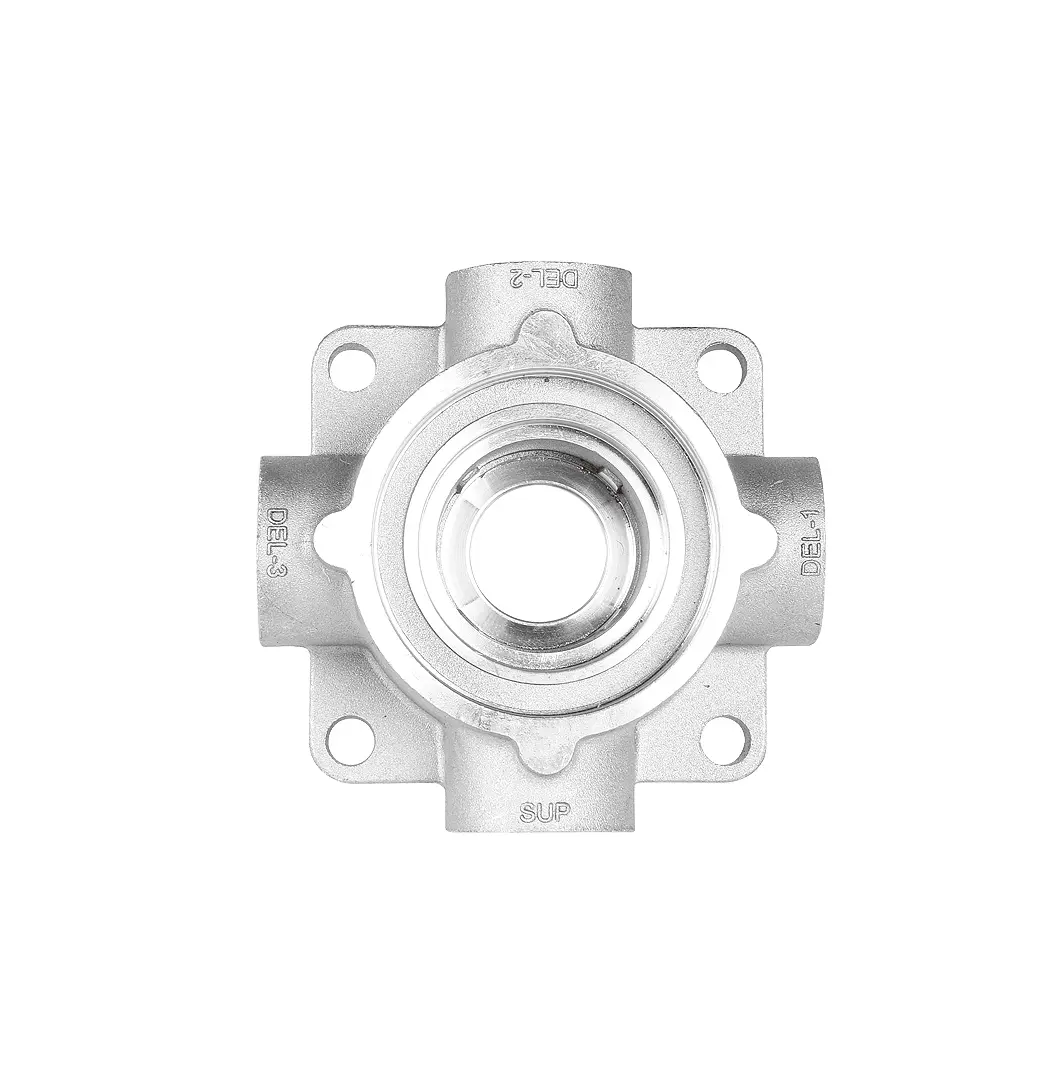

Excessive Oxide Inclusions: Low-temperature molten aluminum has poor fluidity. The oxide film (primarily composed of Al₂O₃) formed during the melting process cannot effectively float to the liquid surface for removal. Instead, it enters the Casting Mold with the molten aluminum, forming "slag inclusion" defects. This defect manifests itself in mechanical property testing of the casting as a sudden drop in tensile strength and a rough, "slag-like" fracture surface. In severe cases, it can even cause the casting to break suddenly during assembly or use. Under-pouring and cold shut: Poorly fluid aluminum molten metal has difficulty filling the complex mold cavity during the pouring process, especially for thin-walled parts or structures with fine ribs, resulting in "under-pouring." If the aluminum molten metal cools and solidifies before fully merging in the mold cavity, a "cold shut" forms—a noticeable linear gap on the surface of the casting, significantly reducing sealing and strength, making it unable to meet the requirements of high-precision applications such as hydraulic components and pressure vessels.

An automotive parts manufacturer mistakenly lowered the melting temperature of 6061 aluminum alloy from the standard 720°C to 680°C. This resulted in a batch of steering knuckle castings being scrapped due to cold shut and slag inclusion defects, resulting in direct economic losses exceeding 500,000 yuan. This case clearly demonstrates the fatal hazards of low-temperature melting.

2. Excessive Temperature: Performance Collapse Caused by "Overburning"

Compared to low temperatures, excessively high melting temperatures are more insidious. Initially, they may only manifest as abnormally good aluminum fluidity, but subsequently, the performance of the casting will plummet. This is primarily manifested in three aspects:

Grain Coarsening: When aluminum is held at high temperatures for too long, atomic movement intensifies, causing the grains to grow continuously, forming coarse columnar or equiaxed crystals. Coarse grains directly lead to a decrease in the plasticity and toughness of the casting. For example, if the melting temperature of ZL101A aluminum alloy exceeds 760°C, its elongation drops from the standard 5% to below 2%, making it unable to withstand impact loads and highly susceptible to safety accidents in load-bearing components such as automotive wheels and engine mounts.

Severe Burnout of Alloying Elements: Low-boiling-point alloying elements such as magnesium and zinc volatilize in large quantities at high temperatures, causing the chemical composition of the casting to deviate from the standard. Taking 5052 aluminum alloy as an example, when the temperature exceeds 750°C, the magnesium content decreases by 0.1%-0.2% for every 10 minutes of holding time. This significantly reduces the corrosion resistance of the resulting casting, and pitting corrosion can occur in a short period of time in humid or salty environments.

Overburning and increased oxidation: When the temperature approaches the solidus temperature of the aluminum alloy, localized melting occurs at the grain boundaries, a phenomenon known as "overburning." Overburned castings can experience surface blistering, deformation, and cracking during subsequent Heat Treatment, and are irreparable. Furthermore, high temperatures accelerate the reaction between molten aluminum and oxygen in the air, producing large amounts of slag. This not only increases metal loss (typically increasing the loss rate from 3% to over 8%) but also further deteriorates the internal quality of the casting.

A domestic motorcycle parts manufacturer raised the melting temperature of ADC12 aluminum alloy to 800°C to improve casting fluidity. As a result, the clutch housings produced developed cracks after only 300 hours of bench testing due to coarse grains and magnesium burnout. The manufacturer was ultimately forced to recall all products, severely damaging its brand reputation.

II. The "Golden Range" of Optimal Melting Temperature: Precise Control Based on Alloy Type

Different grades of aluminum alloy have distinct melting temperature ranges due to their varying compositions, requiring tailoring to the alloy's properties. The following are the temperature control standards and references for several commonly used aluminum alloys:

Aluminum Alloy Grade

Main Application

Recommended Melting Temperature Range

Key Control Points

ADC12

Automotive Parts, Appliance Housings

680-720°C

High silicon content. Silicon particles may aggregate easily at high temperatures. Holding time should be controlled to no more than 30 minutes.

6061

Aerospace, Industrial Profiles

700-730°C

High magnesium content. High-temperature burnout must be prevented. 0.1% beryllium can be added to reduce oxidation.

ZL101A

Engine Cylinders, Pumps

720-750°C

Requires use with refining agents. Temperatures exceeding 760°C may result in overheating.

5052

Shipbuilding, Pressure Vessels

690-720°C

Corrosion resistance depends on magnesium content. Temperature fluctuations should be strictly controlled to no more than 0.1%. ±10°C

Determining an appropriate temperature range is not a fixed rule and requires flexible adjustment based on the melting equipment, charge conditions, and casting requirements:

Equipment factors: Induction furnaces heat up quickly and offer good temperature uniformity, so the upper temperature limit can be appropriately lowered. Resistance furnaces heat up slowly and experience large local temperature variations, so the temperature should be controlled in the middle of the range to avoid low-temperature dead zones.

Charge conditions: New aluminum ingots can be melted at the standard temperature. When recycled material accounts for more than 50%, the temperature should be increased by 10-20°C to ensure that the scale and impurities in the recycled material are fully melted and separated.

Casting requirements: Thin-walled, complex parts require a higher temperature to enhance fluidity; thick-walled, load-bearing parts require a lower upper temperature limit to avoid coarse grains.

III. "Full-Process Management" of Temperature Control: Avoiding Risks at the Source

To precisely control the melting temperature within the "golden range," relying solely on thermometer monitoring is insufficient. A "full-process management system" is required to achieve closed-loop control from pre-melting preparation to post-casting:

1. Pre-melting: Equipment Calibration and Charge Pretreatment

Thermometer Calibration: Before daily melting, calibrate the melting furnace's temperature sensor using a standard thermocouple to ensure an error of no more than ±5°C. For large furnaces, three to four temperature measurement points should be located at various locations within the furnace to avoid localized temperature deviations.

Charge Pretreatment: Returned charge must be cleaned of surface oil, paint, and scale, crushed into small pieces smaller than 50mm, and mixed with fresh aluminum ingots in a ratio of 3:7 to minimize temperature fluctuations during melting. Alloying element additives (such as magnesium ingots and ferrosilicon) must be preheated to 150-200°C to avoid localized cooling caused by direct addition to the cold aluminum melt.

2. During Melting: Dynamic Monitoring and Precise Control

Step-by-Step Heating: Using a "step-by-step heating" process, first heat the charge to 550-600°C, hold for 10 minutes to ensure uniform heating, and then raise the charge to the target temperature to avoid local overheating.

Real-Time Stirring and Degassing: Once the molten aluminum temperature reaches the target range, use a graphite stirrer to stir the charge at a constant speed for 5-8 minutes to ensure uniform composition. Simultaneously, introduce nitrogen or argon for degassing. Maintain a stable temperature during the degassing process to avoid localized cooling caused by the introduction of gas.

Timely Slag Deslagging: Deslagging should be performed every 30 minutes to remove slag and impurities from the liquid surface and minimize its impact on the molten aluminum temperature. Slag removal should be gentle to avoid splashing and temperature loss. 3. Post-Smelting: Holding and Rapid Pouring

Hot-holding control: The aluminum melt should not be held in the furnace for more than 60 minutes. If this exceeds the holding time, the temperature and composition must be retested. If the temperature drops, slowly raise the temperature to the target value. Rapid heating is prohibited.

Rapid pouring: The time from the time the aluminum melt is removed from the furnace to the time it is poured should be controlled within 15 minutes. During the pouring process, use an infrared thermometer to monitor the temperature of the aluminum melt in real time. Ensure that the pouring temperature is 10-20°C lower than the melting temperature (i.e., "pouring temperature = melting temperature - 15°C"). This ensures fluidity and prevents coarse grains in the casting.

IV. Summary: Temperature control is the "lifeline" of casting quality

The quality of aluminum alloy castings is determined from the moment the aluminum melt enters the melting furnace, and the melting temperature is the key variable that determines this outcome. Too low a temperature can lead to uneven composition and casting defects, while too high a temperature can cause coarse grains and element burnout. Both can result in significant financial losses for the company.