+86-13516964051

+86-13516964051 Aluminum Die Casting: A Comprehensive Guide to the Aluminum Die Casting Process

Aluminum Die Casting: A Comprehensive Guide to the Aluminum Die Casting Process

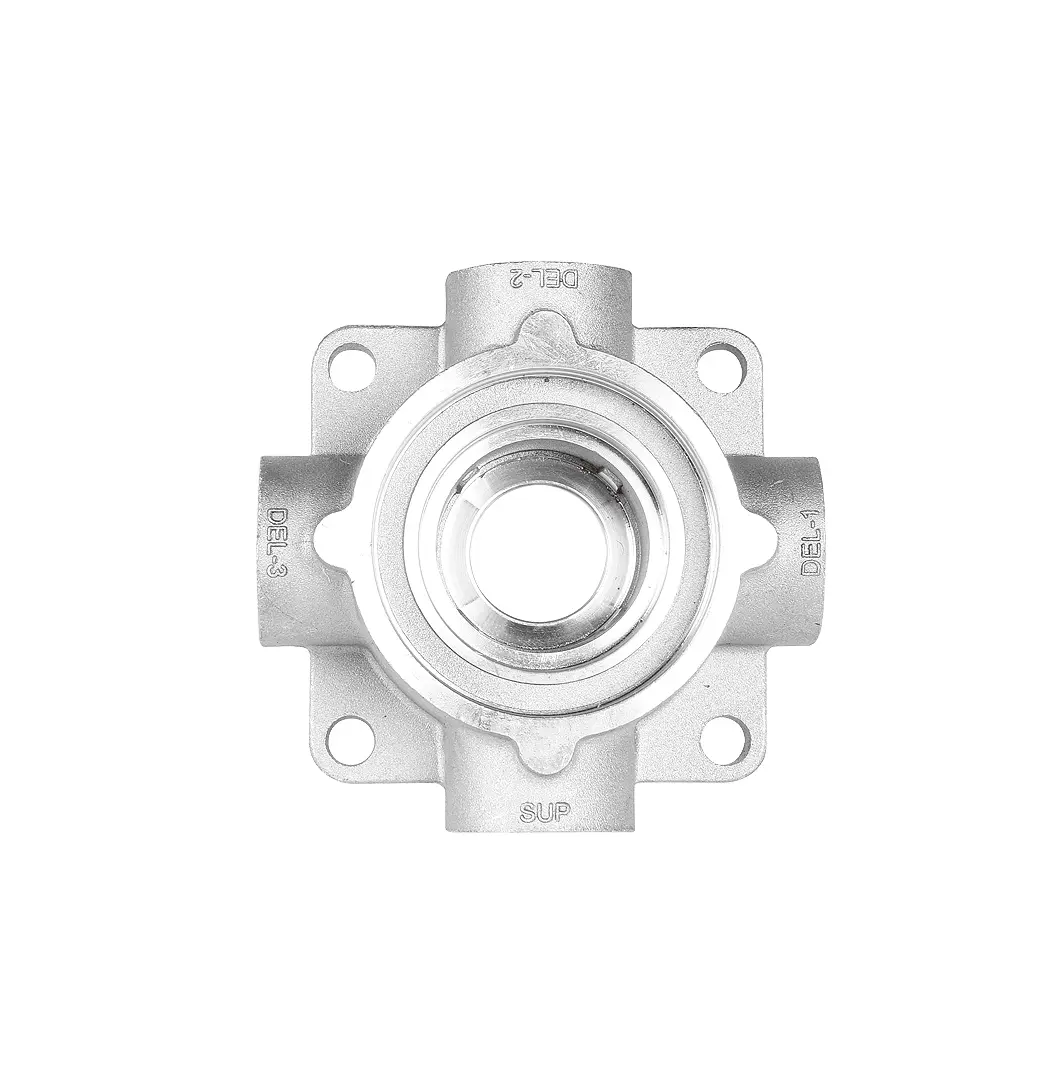

Among the many processes in modern manufacturing, aluminum die casting has become a key technology in the metal forming field due to its advantages such as high efficiency, precision, and cost-effectiveness. Yongkang Hantai Industry and Trade Co., Ltd., a company deeply engaged in aluminum die casting, with its factory located in Yongkang and a new plant in Jiangshan City, Quzhou, is committed to providing customers with high-quality aluminum die-cast products. Below, we provide a comprehensive explanation of the aluminum die casting process.

I. Basic Concepts of Aluminum Die Casting

Aluminum die casting is a process in which molten aluminum alloy is filled into a die-Casting Mold cavity under high pressure and at high speed. After cooling and solidification, a casting of the desired shape and size is obtained. The aluminum alloy used in this process has excellent fluidity and plasticity, which can meet the molding requirements of various complex parts.

Aluminum alloys offer many advantages, such as low density, resulting in lightweight castings, making them ideal for weight-sensitive applications in aerospace, automotive, and other industries. They also offer excellent corrosion resistance, ensuring product life in diverse environments. Furthermore, their excellent electrical and thermal conductivity expands the product's application range.

II. Aluminum Die-Casting Process

(I) Mold Design and Manufacturing

The mold is the core of the aluminum die-casting process, and its design and manufacturing quality directly impact the precision and quality of the casting. When designing the mold, the cavity structure, gate location, and exhaust system must be determined based on the structure, dimensions, and performance requirements of the casting. Mold manufacturing requires the use of high-precision processing equipment to ensure dimensional accuracy and surface quality. Hantai Industry & Trade has a professional mold design and manufacturing team. Leveraging extensive experience and advanced technology, we can create high-quality molds that meet customer needs.

(II) Aluminum Alloy Melting

Aluminum alloy raw materials are mixed according to specific proportions and then placed in a melting furnace for heating and melting. During the melting process, temperature and time must be strictly controlled to ensure uniform composition and purity of the aluminum alloy. Degassing and slag removal are also performed to reduce gases and impurities in the aluminum alloy and improve the quality of the casting. (3) Die Casting

Molten aluminum alloy is poured into the die-casting machine's shot chamber. High pressure is applied through the shot rod, forcing the aluminum alloy into the mold cavity at high speed. During the filling process, parameters such as shot speed and pressure must be carefully controlled to ensure the quality of the casting.

(4) Casting Cleaning and Finishing

After die casting, the casting may have burrs and flash on its surface, which require cleaning and finishing. Machining or manual polishing can be used to remove surface defects and achieve the specified dimensions and surface quality.

(5) Heat Treatment

For castings with high performance requirements, heat treatment is also required. Heat treatment can alter the internal structure of the aluminum alloy and improve mechanical properties such as strength, hardness, and toughness.

(6) Surface Treatment

To improve corrosion resistance, wear resistance, and aesthetics, castings are typically surface treated. Common surface treatment methods include anodizing, electroplating, and spraying.

III. Advantages of Aluminum Die-Casting

(I) High Production Efficiency

Aluminum die-casting utilizes highly automated production equipment, enabling continuous production and significantly improving production efficiency. Compared to other casting processes, aluminum die-casting boasts a short production cycle, enabling rapid fulfillment of customer orders.

(II) High Casting Precision

Due to the high precision of the molds and the high pressure used to form the parts, aluminum die-casting castings exhibit excellent dimensional accuracy and surface quality, reducing subsequent processing workload and lowering production costs.

(III) High Material Utilization

Aluminum die-casting is a near-net-shape process, resulting in casting dimensions close to those of the final product. This results in high material utilization and minimizes material waste.

(IV) Ability to Form Complex Shapes

Aluminum die-casting is capable of forming a variety of complex shapes, particularly those with thin walls and complex internal cavities, offering unique advantages.

IV. Hantai Industry & Trade's Aluminum Die-Casting Strengths

Yongkang Hantai Industry & Trade Co., Ltd. possesses advanced aluminum die-casting production and testing equipment, as well as a professional technical and management team. After years of development, our Yongkang factory has accumulated extensive production experience and technical expertise, enabling us to provide customers with a wide range of high-quality aluminum die-casting products.

To expand production and enhance our competitiveness, we built a new factory in Jiangshan City, Quzhou. The new facility utilizes more advanced production processes and equipment, further improving production efficiency and product quality. Furthermore, the new facility prioritizes environmental protection and safe production, striving to create a green, efficient, and safe production base.

Our company consistently prioritizes customer focus and quality, continuously improving product quality and service. We offer comprehensive support and assurance in product design, mold manufacturing, production, processing, and after-sales service.

Aluminum die-casting, as an advanced metal forming technology, plays a vital role in modern manufacturing. Yongkang Hantai Industry and Trade Co., Ltd. has established a strong reputation in the aluminum die-casting industry thanks to its strong capabilities and high-quality service. If you require aluminum die-casting products, consider choosing Hantai Industry and Trade. We are confident that we will provide you with satisfactory products and services.