+86-13516964051

+86-13516964051 A Comprehensive Approach to Enhancing the Surface Quality of Aluminum Alloy Die Castings through Improved Infiltration Technology

Introduction

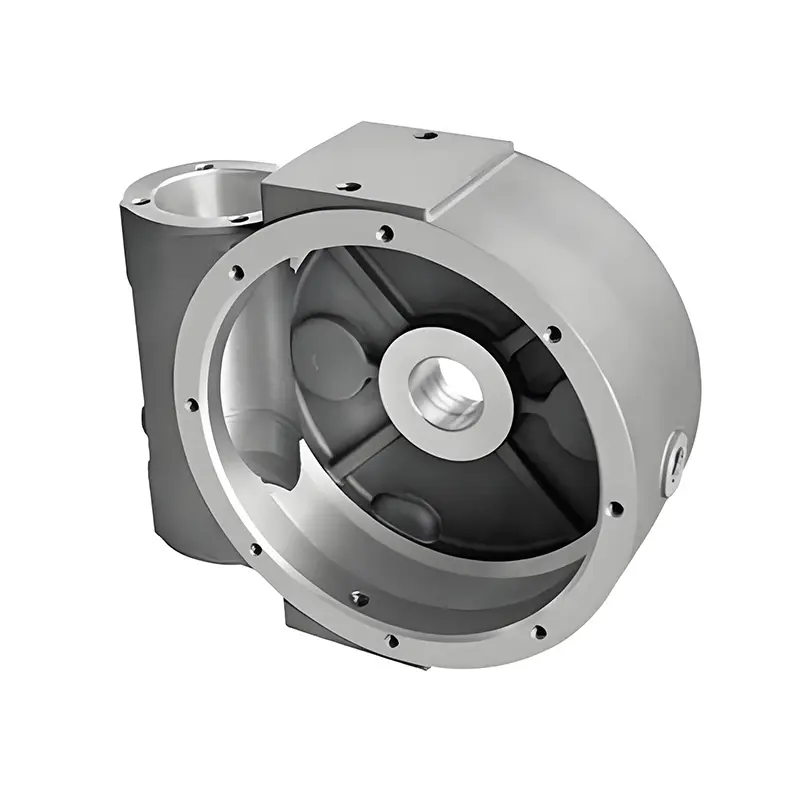

Aluminum alloy die casting is a widely used manufacturing process in the automotive, aerospace, and consumer electronics industries due to its ability to produce complex shapes with high precision and excellent mechanical properties. However, surface quality issues such as blackening, yellowing, and powder residue have long been a challenge for manufacturers. These problems not only affect the aesthetic appeal of the products but also impact their functionality and durability. To address these challenges, an improved infiltration process has been developed, which significantly enhances the surface quality of Aluminum Alloy Die Castings.

Background of Infiltration Technology

Infiltration technology has been used for decades to seal porosities and defects in die castings. The traditional process involves immersing the casting in a liquid infiltrant, which then penetrates the pores under vacuum or pressure conditions. After curing, the infiltrant forms a solid barrier that prevents leakage and improves the mechanical properties of the casting. However, this conventional method has limitations, such as uneven distribution of the infiltrant and difficulty in removing excess material from the surface, leading to the aforementioned surface quality issues.

The Improved Infiltration Process

Pre-Treatment

The first step in the improved infiltration process is the pre-treatment of The Die Casting. This involves cleaning and drying the casting to remove any oil, water, or impurities from the surface. This step is crucial as it ensures that the infiltrant can penetrate the pores effectively without being hindered by contaminants. The cleaning process typically involves the use of specialized detergents and solvents, followed by thorough rinsing and drying at elevated temperatures to ensure complete removal of moisture.

Vacuum and Pressure Infiltration

Once the casting is pre-treated, it is placed in an infiltration tank where it undergoes a vacuum and pressure infiltration process. The tank is first evacuated to create a vacuum, which helps to remove any air trapped in the pores of the casting. This is followed by the introduction of the infiltrant, which is drawn into the pores by the vacuum. After the infiltrant has been allowed to penetrate the pores, the pressure inside the tank is gradually increased to ensure that the infiltrant reaches all areas of the casting. This step is critical in ensuring that even the smallest and most complex pores are filled with the infiltrant.

Post-Treatment

After the infiltration process, the casting undergoes a series of post-treatment steps to remove any excess infiltrant and to cure the material within the pores. The first step is to rotate the casting in a washing solution to remove any infiltrant that may have adhered to the surface. This is followed by a curing process where the casting is heated to a specific temperature to solidify the infiltrant within the pores. The use of a rotating curing tank has been shown to be particularly effective in ensuring that the infiltrant is evenly distributed and fully cured.

Final Cleaning and Drying

The final steps in the improved infiltration process involve cleaning and drying the casting to remove any remaining residues and to prepare it for further processing or use. The casting is thoroughly washed in a rinsing tank to remove any remaining infiltrant or cleaning solution. This is followed by drying in a specialized drying tank, which uses high-speed hot air to quickly and evenly remove any moisture from the surface. The use of a rotating drying tank with strategically placed heat sources and powerful fans ensures that the casting is thoroughly dried without causing any damage to the surface.

Benefits of the Improved Infiltration Process

The improved infiltration process offers several benefits over traditional methods. Firstly, it significantly reduces the occurrence of surface defects such as blackening, yellowing, and powder residue. This is achieved through the careful control of the infiltration process and the use of specialized equipment such as rotating curing and drying tanks. Secondly, the process ensures that the infiltrant is evenly distributed and fully cured within the pores of the casting. This not only improves the mechanical properties of the casting but also enhances its resistance to corrosion and wear. Finally, the improved process is more efficient and environmentally friendly, reducing the amount of waste generated and the overall environmental impact of the manufacturing process.

Case Studies and Applications

The improved infiltration process has been successfully applied in various industries, particularly in the automotive and aerospace sectors where high-quality surface finishes are critical. For example, a major automotive manufacturer reported a significant reduction in the number of defective castings after implementing the improved infiltration process. This not only improved the quality of their products but also reduced production costs and increased overall efficiency. Similarly, an aerospace company reported improved mechanical properties and surface quality in their aluminum alloy die castings, leading to enhanced product performance and reliability.

Conclusion

The improved infiltration process represents a significant advancement in the manufacturing of aluminum alloy die castings. By carefully controlling the infiltration process and using specialized equipment, manufacturers can significantly enhance the surface quality of their products while also improving their mechanical properties and overall performance. As the demand for high-quality die castings continues to grow in industries such as automotive and aerospace, the improved infiltration process offers a reliable and efficient solution to meet these demands.