+86-13516964051

+86-13516964051 Wholesale Metal Casting Methods: Best Suppliers and Factories for Your Needs

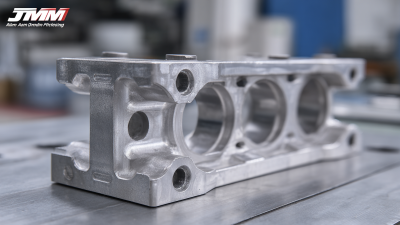

At Yongkang Hantai Industry And Trade Co., Ltd., we specialize in a wide array of metal casting methods designed to meet the unique needs of wholesale buyers. Our advanced manufacturing facility is equipped with the latest technology, enabling us to produce high-quality castings that satisfy your specific requirements. We provide a comprehensive range of services, ensuring meticulous attention to detail throughout the production process. Whether you need complex designs or large-volume orders, our skilled team is dedicated to supporting you. We take pride in our reliability and commitment to quality, essential characteristics for B2B partnerships. By collaborating with us, you benefit from prompt delivery and exceptional customer support at every stage of your project. Partner with us for your metal casting needs and enhance your product offerings with our expertise.Best Way To Choose Metal Casting Methods Factory Manufacturer

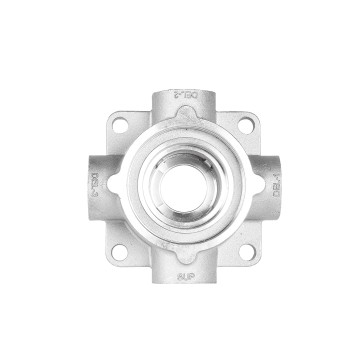

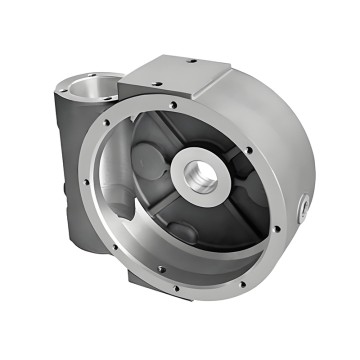

Choosing the right metal casting methods and factory manufacturer is crucial for businesses looking to source high-quality components, especially in the automotive industry. At Yongkang Hantai Industry & Trade Co., Ltd., established in 1997, we understand the importance of combining technological innovation with rigorous quality control. Our commitment to producing Precision Parts ensures that our clients receive products that meet stringent industry standards. When evaluating potential manufacturers, consider several key factors. First, assess the range of metal casting methods they offer. Different techniques, such as sand casting, investment casting, and die casting, can significantly impact the performance and cost of the final product. Additionally, it's essential to check the manufacturer's experience and specialization in the desired application. At Hantai, we have honed our skills over decades and pride ourselves on delivering superior components tailored for the automotive sector. Lastly, prioritize communication and support when selecting a metal casting partner. A manufacturer that values collaboration can help optimize designs and enhance product quality throughout the production process. With our focus on technological advancement and customer satisfaction, Yongkang Hantai is dedicated to being your trusted supplier, ensuring you receive the highest-quality parts that drive your success in the global market.

Best Way To Choose Metal Casting Methods Factory Manufacturer

| Casting Method | Material Types | Typical Applications | Advantages | Considerations |

|---|---|---|---|---|

| Sand Casting | Aluminum, Iron, Steel | Engine Blocks, Frames | Cost-effective, versatile | Surface finish may require post-processing |

| Die Casting | Zinc, Aluminum, Magnesium | Automotive Parts, Electronics | High precision, smooth surface finish | Higher initial setup cost |

| Investment Casting | Stainless Steel, Bronze | Aerospace, Medical Devices | Excellent dimensional accuracy | Longer lead times |

| Centrifugal Casting | Copper, Steel | Piping, Engine Components | Strengthens outer layer | Requires specialized equipment |

| Shell Molding | Cast Iron, Aluminum | Agricultural Equipment, Machinery | Good precision and surface finish | Limited to smaller parts |

China Top Metal Casting Methods Factory Supplier

B

Benjamin Scott

Quality is truly exceptional! Their customer service was impressive, addressing my queries with patience and expertise.

02 July 2025

M

Madison Hall

Superb quality! The after-sales support was highly responsive and knowledgeable, making for a great buying experience.

17 May 2025

C

Colton Thompson

High-quality item! The professionalism of the after-sales support team was notable; they really knew their stuff!

16 June 2025

L

Landon Davis

Impressive quality product! The after-sales service was prompt and truly professional. Highly recommend!

21 June 2025

E

Ellison Carter

Fantastic product! The support team was genuinely knowledgeable and provided excellent post-sale assistance.

16 May 2025

J

Jasmine Clark

What a high-quality product! The support team was thorough, knowledgeable, and very professional in handling my queries.

03 July 2025