+86-13516964051

+86-13516964051 Premium Heat Treatment Aluminum from Top Suppliers & Manufacturers - High Quality Guaranteed

When seeking dependable solutions for aluminum heat treatment, quality and service stand out as essential. Our wholesale offerings guarantee superior products customized to meet your unique requirements. As a leading supplier, we focus on aluminum heat treatment processes that improve strength and durability, making our materials ideal for a wide range of applications.7 Key Tips To Heat Treatment Aluminum Trusted by Pros Stands Out

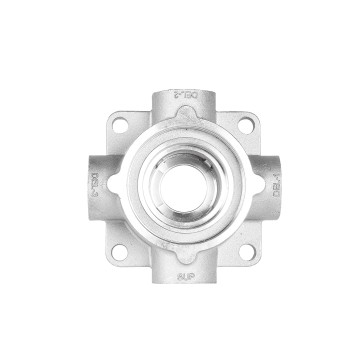

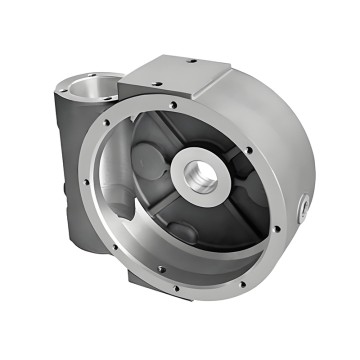

When it comes to heat treatment of aluminum, professionals in the automotive industry turn to trusted guidelines that ensure both quality and efficiency. At Yongkang Hantai Industry & Trade Co., Ltd., we understand that superior heat treatment processes are vital for producing durable and reliable parts. Established in 1997, our company is committed to technological innovation and continuous quality improvement, setting us apart in the competitive market. One of the key aspects of effective heat treatment is selecting the right temperature and timing. Professionals recommend precise control of these parameters to enhance the mechanical properties of aluminum, thereby improving strength and durability. Additionally, employing advanced techniques such as solution heat treatment and aging can further refine the material’s performance, making it more suitable for the demanding automotive applications. At Hantai, we leverage our extensive experience to offer high-quality Aluminum Parts that meet international standards, ensuring they withstand rigorous testing and usage. Moreover, the significance of surface treatment cannot be understated. Applying coatings or surface modifications post-heat treatment can significantly improve corrosion resistance and aesthetic appeal. Our dedicated team at Yongkang Hantai focuses on delivering custom solutions tailored to the specific needs of our global partners, ensuring that every component not only meets quality thresholds but also exceeds expectations in terms of performance and reliability. Trust us to be your strategic partner in sourcing top-notch aluminum parts for your automotive needs.

7 Key Tips To Heat Treatment Aluminum Trusted by Pros Stands Out

| Tip | Description | Benefit |

|---|---|---|

| Understand the Alloy | Know the specific aluminum alloy you are working with to determine the right treatment. | Ensures optimal heat treatment results and performance. |

| Control Temperature | Maintain precise temperature during the heating cycle. | Prevents overheating and preserves material integrity. |

| Time Management | Follow the recommended time for each heat treatment stage. | Allows for complete structural changes in the metal. |

| Quenching Techniques | Choose between air, oil, and water quenching based on the alloy. | Facilitates the desired hardness and properties of the material. |

| Aging Process | Implement artificial aging to enhance strength. | Improves mechanical properties post-treatment. |

| Use of Equipment | Utilize high-quality furnaces and cooling systems. | Ensures uniform heating and consistent results. |

| Post-Treatment Inspection | Conduct thorough inspections after treatment. | Identifies any defects and ensures quality control. |

Best Brands For Heat Treatment Aluminum Trusted by Pros Leads the Global Market

L

Lucas Wilson

Great quality product! The customer service team was very professional, providing all the information I needed. Highly recommend!

29 June 2025

A

Anthony Baker

This product is outstanding! The customer service team was professional and helped me with all my inquiries.

10 May 2025

J

Jackson Thompson

Outstanding craftsmanship! The customer support team was exceptional in guiding me through every step.

26 June 2025

E

Ellison Carter

Fantastic product! The support team was genuinely knowledgeable and provided excellent post-sale assistance.

16 May 2025

G

Grayson White

The quality is impeccable! The professionalism and expertise of the after-sales support team were very helpful.

02 July 2025

H

Hazel Mitchell

Love the durability and quality of this item! Customer service was very professional and knowledgeable, which I appreciated.

24 May 2025