+86-13516964051

+86-13516964051 Expert Wholesale Foundry Casting Services for High-Quality Manufacturing Solutions

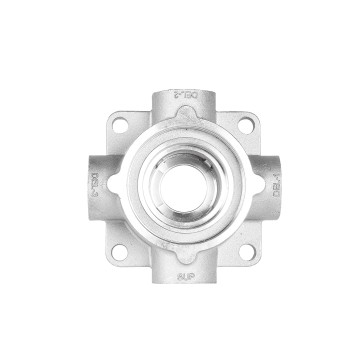

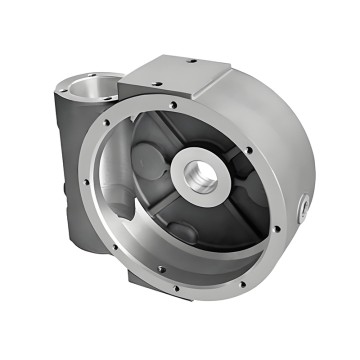

Yongkang Hantai Industry And Trade Co., Ltd. specializes in high-quality ODM solutions in the foundry casting sector. Our state-of-the-art facilities and skilled professionals ensure exceptional precision and quality in every product we create. We cater to various industries, providing customized casting options that meet your specific requirements. With our extensive expertise and commitment to customer satisfaction, you can rely on us for outstanding casting solutions that bring your projects to fruition. Partner with us for seamless manufacturing support and exceptional results.7 Key Tips To Foundry Casting Process in 2025 Global Reach

In 2025, the global foundry casting process is set to undergo transformative changes that will enhance efficiency, quality, and sustainability. For buyers seeking high-quality parts in the automotive industry, understanding these trends is essential for informed procurement decisions. Here are seven key tips to navigate the evolving landscape. First, prioritize suppliers who embrace technological innovation. Companies like Yongkang Hantai Industry & Trade Co., Ltd., with over two decades of experience, exemplify this commitment by continuously advancing their manufacturing techniques to produce precision components. By choosing partners who invest in modern technology, you can ensure that the parts you source are not only high-quality but also tailored to meet the latest industry standards. Second, focus on suppliers that demonstrate a strong commitment to quality improvement. In an era where consumer expectations are higher than ever, choosing manufacturers that prioritize quality control will mitigate risks and enhance product reliability. As your business expands globally, partnering with industry leaders dedicated to excellence can significantly impact your supply chain's overall performance. By leveraging these insights, you can make strategic decisions that will not only meet the demands of today's automotive market but also position your business for success in the competitive global landscape. Embrace innovation and quality as you look toward the future of foundry casting.

7 Key Tips To Foundry Casting Process in 2025 Global Reach

| Tip No. | Tip Description | Potential Impact | Implementation Timeline |

|---|---|---|---|

| 1 | Invest in advanced simulation software | Reduce defects by 30% | 6 months |

| 2 | Enhance material quality control | Increase product lifespan by 20% | 3 months |

| 3 | Adopt green foundry technologies | Lower emissions by 40% | 1 year |

| 4 | Implement real-time monitoring systems | Improve operational efficiency by 25% | 8 months |

| 5 | Train workforce on new casting technologies | Enhance workforce productivity by 15% | 4 months |

| 6 | Establish strategic partnerships for supply chain | Reduce costs by 20% | 1 year |

| 7 | Invest in robotic automation | Boost production rate by 50% | 2 years |

Discovering Foundry Casting Process Factory Manufacturers You Can Rely On

N

Noah Clark

Impressive product quality! The after-sales service team went above and beyond to assist me, showcasing their professionalism. An excellent choice!

01 June 2025

L

Logan White

Outstanding quality and customer service! The team handled my queries with professionalism, making my experience smooth and enjoyable.

07 June 2025

A

Anthony Baker

This product is outstanding! The customer service team was professional and helped me with all my inquiries.

10 May 2025

H

Hazel Mitchell

Love the durability and quality of this item! Customer service was very professional and knowledgeable, which I appreciated.

24 May 2025

E

Elena Carter

Impressive product quality! The professionalism exhibited by the support staff made my experience extremely positive.

03 June 2025

A

Autumn Brooks

Impressive quality and great performance! The support staff provided assistance with professionalism and detail.

09 June 2025