+86-13516964051

+86-13516964051

Excellent application of aluminum alloy low pressure casting in the electromechanical industry

description1

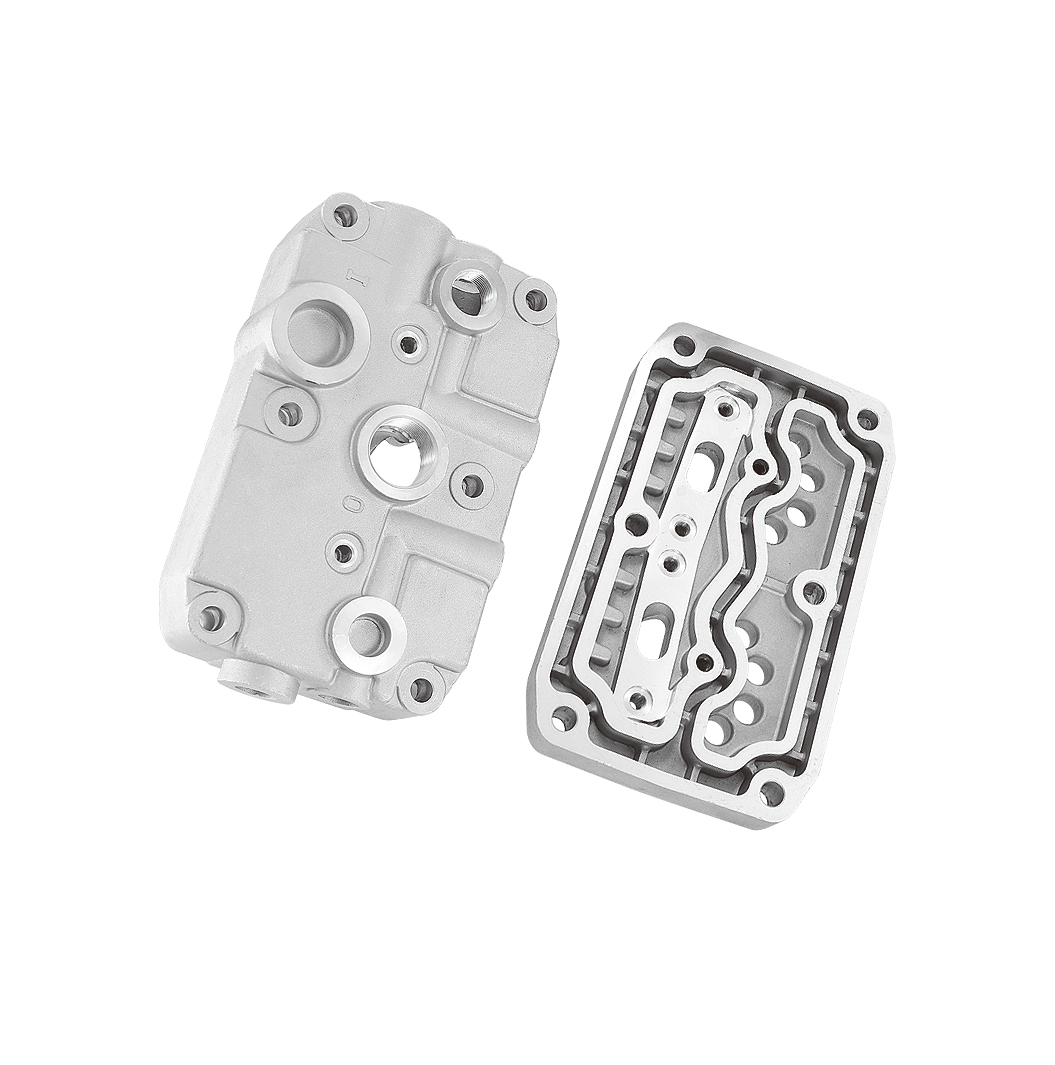

cylinder assembly

Application scenarios

In the electromechanical field, 52 cylinder assemblies are widely used in various pneumatic equipment, automated mechanical devices, etc. For example, on an automated production line, the cylinder can drive the mechanical arm to perform tasks such as grabbing, handling, and assembly; in a material conveying system, the cylinder can realize the opening and closing of valves, the lifting and lowering of silos, and other actions to ensure the continuity and stability of production.

Product advantages

The 52 cylinder assembly produced by Yongkang Hantai Industry and Trade Co., Ltd. using aluminum alloy low-pressure casting technology has the characteristics of light weight, high strength, and strong corrosion resistance. The reasonable casting structure design ensures the reliability and durability of the cylinder under frequent movements. Its good sealing can effectively reduce gas leakage and improve the working efficiency of the cylinder. Compared with cylinders made of traditional materials, aluminum alloy cylinder assemblies reduce the overall weight of the equipment while also reducing energy consumption, and can meet the requirements of modern electromechanical equipment for high efficiency, energy saving, and compactness.

Aluminum die castings

Application scope

Aluminum die castings are widely used in the electromechanical industry and are often used in motor housings, electrical control box housings, lamp housings, etc. Taking the motor housing as an example, it not only needs to provide mechanical support and protection for the stator, rotor and other components inside the motor, but also needs to have good heat dissipation performance to ensure that the motor does not overheat during operation and maintain its normal working state and service life.

Product features

The aluminum die castings produced by the company, with the advantages of low-pressure casting of aluminum alloy, can achieve high-precision molding of complex shell shapes. The die casting has a smooth surface and good appearance quality, and can meet the appearance requirements without too much subsequent processing. At the same time, the excellent thermal conductivity of aluminum alloy makes the aluminum die casting have excellent heat dissipation effect, which can effectively reduce the heat generated by motors and other equipment during operation and ensure the stable operation of the equipment. In addition, aluminum die castings also have good electromagnetic shielding performance, which can prevent electromagnetic interference and play a key role in the normal operation of electronic and electrical equipment.

High-pressure die-casting of aluminum shell die-casting base

Application

The base of aluminum shell die-casting plays the role of bearing and fixing key components in electromechanical equipment, such as the base installed at the bottom of large machine tools, automated testing equipment, etc. The high-pressure die-casting process is an important link in the production of aluminum shell die-casting bases, which can further improve the density and strength of the base to bear the weight of the equipment and various loads during the working process.

Product performance

Yongkang Hantai Industry and Trade Co., Ltd. uses aluminum alloy low-pressure casting combined with high-pressure die-casting technology to produce aluminum shell die-casting bases with extremely high dimensional accuracy and good mechanical properties. The installation holes of the base are precise, which can ensure the precise assembly of the equipment; its high strength and good fatigue resistance make the base remain stable under long-term vibration and impact loads, and it is not easy to deform and damage, providing a solid foundation for the safe and reliable operation of electromechanical equipment.

Processing of carbon steel precision castings

Application areas

Carbon steel precision castings are also indispensable in the electromechanical industry, especially in the manufacture of some parts with high requirements for strength and wear resistance. For example, the transmission parts such as the spindle and gears of machine tools, as well as the key parts such as the crankshaft and connecting rod in automobile engines, carbon steel precision castings can meet their high precision and high hardness requirements.

Product Highlights

The company has mature carbon steel precision casting processing capabilities, and uses advanced casting technology and precision processing equipment to produce carbon steel castings with high dimensional accuracy and complex shapes. From casting blanks to finished products, a strict quality control system ensures the accuracy and quality of each link. After fine processing, the carbon steel precision castings have low surface roughness, and the accuracy of the tooth shape, journal and other parts reaches the micron level, which can ensure the efficient and stable operation of the transmission system of electromechanical equipment, extend the service life of the equipment, and reduce maintenance costs.

Low-pressure casting of aluminum castings

Application scenario expansion

In addition to the application of the above products, low-pressure casting of aluminum castings also has broad prospects in some emerging electromechanical fields. For example, in the manufacture of motor controller housings, battery pack housings and other components of new energy vehicles, low-pressure casting technology of aluminum castings is widely used due to its advantages such as light weight, high strength and good heat dissipation performance. At the same time, in 5G communication base station equipment, such as filter housings, radiators, etc., aluminum castings low-pressure castings are also favored for their excellent electromagnetic compatibility and heat dissipation performance.

Product advantage upgrade

Yongkang Hantai Industry and Trade Co., Ltd. relies on rich experience and technical accumulation to continuously innovate in low-pressure casting of aluminum castings. Through precise control of casting parameters and optimization of mold design, the internal structure of the aluminum castings produced is more uniform and dense, and the mechanical properties are excellent. The company is also equipped with advanced testing equipment to conduct strict quality inspections on each batch of aluminum castings, including dimensional inspection, non-destructive testing, mechanical properties testing, etc., to ensure that the products meet or even exceed the quality requirements of customers, and provide high-quality and reliable aluminum castings for the electromechanical industry.

01

Detailed explanation of aluminum alloy low-pressure casting technology

Aluminum alloy low-pressure casting is an advanced casting process between gravity casting and high-pressure casting. In the low-pressure casting process, the liquid aluminum alloy is slowly pressed into the mold cavity by controlling the pressure, so that the metal liquid can be filled smoothly under lower pressure. Compared with traditional casting processes, this technology has many significant advantages:

High casting quality: Due to the stable filling of the molten metal, turbulence and air entrainment are reduced, and the probability of defects such as pores and looseness in the casting is effectively reduced. At the same time, the pressure in the mold cavity can promote better shrinkage compensation of aluminum alloy, make the casting structure more dense, and significantly improve the dimensional accuracy and surface finish, which can meet the requirements of the electromechanical industry for complex shapes, high precision and high strength of parts.

High material utilization rate: Reasonable pouring system design and low-pressure casting characteristics make aluminum alloy materials less lost during the casting process. Compared with other casting methods, it can save raw materials and reduce production costs, especially for precious aluminum alloy materials. The economic benefits are more obvious.

Good production safety: Low-pressure casting uses lower pressure for operation. Compared with processes such as high-pressure casting, it is less dangerous during the production process, which is more beneficial to the safety of operators and equipment, and is conducive to enterprises creating a safe and stable production environment.

02

Supporting services of Yongkang Hantai Industry and Trade Co., Ltd.

Yongkang Hantai Industry and Trade Co., Ltd. not only focuses on the production of aluminum alloy low-pressure casting products, but also provides customers with a full range of supporting services. The company undertakes heat treatment, aluminum alloy surface hard oxidation processing and other businesses. The heat treatment process can further improve the mechanical properties of the castings, such as hardness, wear resistance and toughness, so that they can meet the use requirements under different working conditions; the hard oxidation treatment of the aluminum alloy surface gives the product better corrosion resistance, wear resistance and decorative properties, prolongs the product life and enhances the product's competitiveness in the market.

In addition, the company has a professional technical team that can provide one-stop solutions from product design, mold development, casting process formulation to post-processing according to the specific needs of customers. Whether it is small batch customization or large-scale production, Yongkang Hantai Industry and Trade Co., Ltd. can rely on its strong production capacity and flexible production organization to deliver products on time, according to quality and quantity, and create an efficient and stable supply chain system for customers.