+86-13516964051

+86-13516964051 Advantages of Die Casting: Insights from Top Wholesale Suppliers and Factories

Die casting offers significant benefits for OEM projects, enhancing both efficiency and precision. With features like reduced material waste and outstanding dimensional accuracy, it is an optimal choice for a wide range of applications. At Yongkang Hantai Industry And Trade Co., Ltd., we specialize in high-quality die casting solutions customized to meet your specific needs. Our wealth of experience ensures we provide cost-effective products without compromising on quality. Serving industries such as automotive, electronics, and consumer goods, our advanced techniques will give you a competitive advantage. Partnering with us means working with a dedicated team that prioritizes timely deliveries and exceptional craftsmanship. Let's collaborate to harness the various Die Casting Advantages for your upcoming project!

Why Choose Die Casting Advantages Products Manufacturer

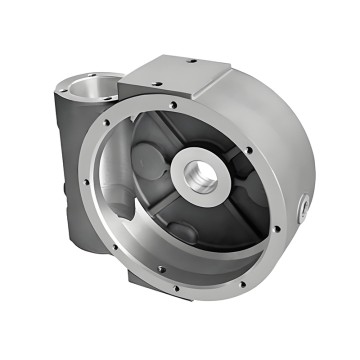

When it comes to sourcing reliable parts and components for the automotive industry, choosing the right manufacturer can make all the difference. At Yongkang Hantai Industry & Trade Co., Ltd., established in 1997, we pride ourselves on our dedication to technological innovation and quality enhancement. Our extensive experience in die casting allows us to produce superior products that meet the stringent demands of our global clients. One of the primary advantages of die casting is its ability to create highly detailed and complex shapes that are both durable and lightweight. This manufacturing process not only reduces waste materials but also enhances production efficiency, allowing us to deliver high-quality components in a timely manner. Our commitment to excellence ensures that every part we manufacture adheres to the highest industry standards, making us a trustworthy partner for your automotive needs. By choosing Yongkang Hantai as your die casting products manufacturer, you gain access to a wealth of expertise and cutting-edge technology. We understand that the automotive industry requires precision, reliability, and consistency; our focus on continuous improvement means we are always adopting the latest advancements to better serve our clients. Partner with us and experience the benefits of high-quality, innovative parts designed to enhance your products and propel your business forward.

Why Choose Die Casting Advantages Products Manufacturer

| Feature | Advantage | Applications |

|---|---|---|

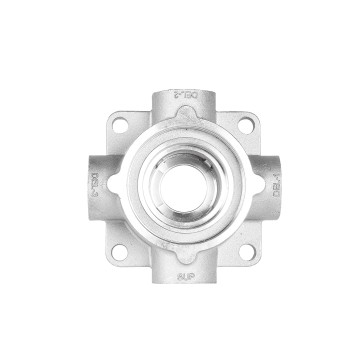

| High Precision | Tight tolerances and intricate designs are achievable, reducing the need for additional machining. | Automotive, Aerospace |

| Cost Effectiveness | Lower material waste and fast production rates lead to reduced costs for mass production. | Consumer Electronics, Lighting Fixtures |

| Durability | Cast Parts are robust and offer enhanced performance in demanding environments. | Heavy Machinery, Industrial Equipment |

| Material Versatility | Ability to work with a variety of metals, including aluminum, zinc, and magnesium. | Medical Devices, Home Appliances |

| Surface Finish Options | Wide range of surface finishes available, enhancing aesthetics and corrosion resistance. | Architectural Components, Decorative Items |

China Top Die Casting Advantages Manufacturer Supplier

I

Isabella Garcia

The durability of this product is impressive. The after-sales support exceeded my expectations with their quick response and expertise.

16 May 2025

E

Eli Adams

The product quality is exceptional! I was impressed with the support team’s expertise and quick response to my questions.

19 June 2025

E

Elias Young

Incredible quality craftsmanship! The customer service team was knowledgeable and made the process a breeze.

25 June 2025

A

Asher Baker

The commitment to quality is evident! Their after-sales support team went above and beyond in professionalism.

26 June 2025

H

Hazel Mitchell

Love the durability and quality of this item! Customer service was very professional and knowledgeable, which I appreciated.

24 May 2025

M

Maddox Murphy

Top-tier quality! The professionalism of the customer service representatives was commendable; they really knew their stuff.

06 June 2025