+86-13516964051

+86-13516964051

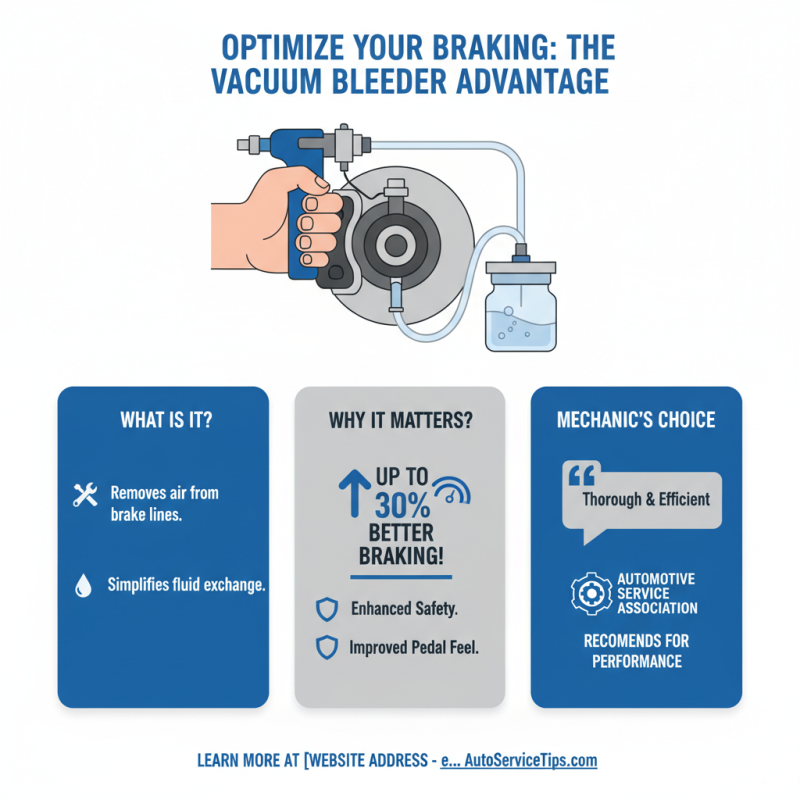

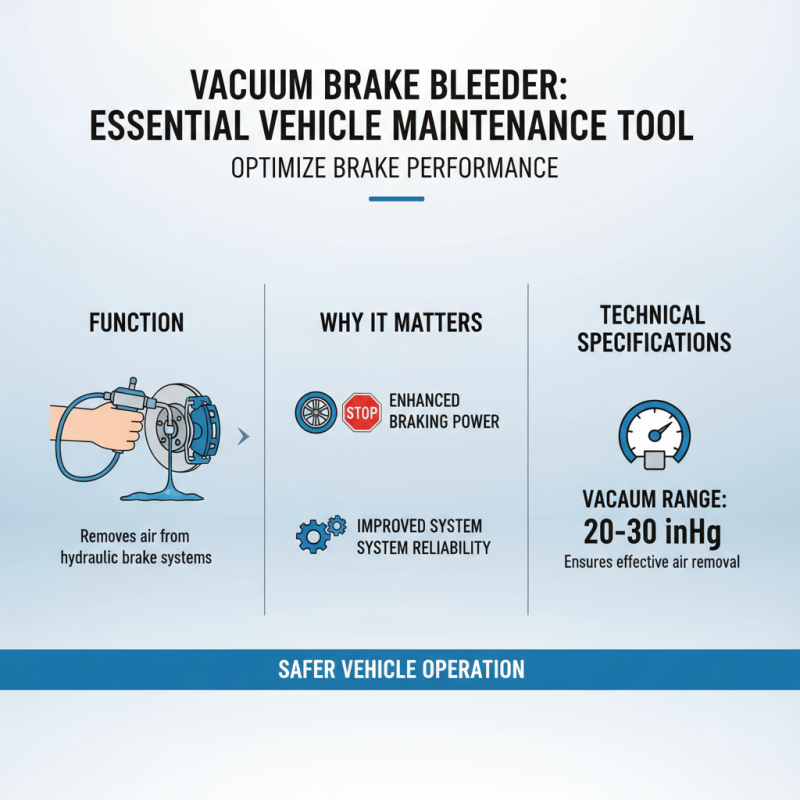

A Vacuum Brake Bleeder is an essential tool for maintaining the braking system in vehicles. It works by creating a vacuum that helps remove air bubbles from brake lines. This is crucial for ensuring effective braking performance. Many car owners grapple with the challenges of air in the brake system. A vacuum bleeder simplifies this process, making it accessible even to those without extensive mechanical knowledge.

Using a Vacuum Brake Bleeder can save time and effort. Instead of manually pumping the brake pedal, the device does the hard work. This tool often provides a cleaner and more efficient way to bleed brakes. However, it’s important to note that not all vacuum bleeders are created equal. Some might require additional practice to master, leading to potential frustration.

The need for proper brake maintenance cannot be overstated. An air-filled brake line can lead to dangerous situations. It’s vital to periodically check and bleed brakes to ensure safety. A Vacuum Brake Bleeder offers a solution, but it also requires care in its use. Proper handling and frequent checks can prevent costly mistakes. Emphasizing skill and caution can make a difference in overall vehicle safety.

Vacuum brake bleeders are essential tools for automotive maintenance. They simplify the process of removing air from brake lines. Air in the brake system can lead to reduced braking efficiency. Many mechanics recommend vacuum bleeding for its thoroughness. A report from the Automotive Service Association highlights that air removal can increase brake performance by up to 30%.

Using a vacuum brake bleeder is straightforward. The device creates a vacuum that draws brake fluid and air out of the system. This method avoids common issues like fluid spillage and contamination. Improper bleeding can lead to serious safety risks. For instance, a poorly bled system may have a spongy brake feel. The consequences could be disastrous, affecting vehicle control.

However, vacuum bleeders have limitations. They can sometimes struggle with older vehicles that use specific configurations. Not all systems are compatible with vacuum bleeding. Mechanics should always verify the system type before use. Understanding these nuances is crucial. It ensures that the process is effective and safe, contributing to optimal vehicle performance.

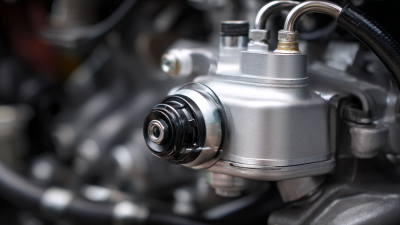

A vacuum brake bleeder is a tool that simplifies the process of bleeding brakes. Its mechanism relies on creating a vacuum to draw brake fluid through the system, eliminating air. When air gets trapped in brake lines, it can lead to a spongy brake feel. This tool helps ensure that your brake system remains efficient and responsive.

During operation, the bleeder attaches to the brake bleeder valve. A vacuum is then created, pulling fluid from the reservoir. This method can reduce the risk of introducing more air into the system. A report from the Automotive Brake Association indicates that proper brake bleeding can improve braking performance by up to

30%. This accuracy and efficiency can enhance safety on the road.

Tips: Before starting, ensure the brake fluid reservoir is filled to the recommended level. Pay attention to the fluid quality. Contaminated fluid can lead to worse performance. One common pitfall is not releasing the bleeder valve fully, which can trap air. Regular maintenance can prevent issues, but always reflect on the effectiveness of your techniques.

Vacuum brake bleeders are essential tools in automotive maintenance. They simplify the process of bleeding brake lines efficiently. With a vacuum pump, these devices create negative pressure. This pressure draws fluid from the master cylinder to remove air bubbles from the system.

The benefits of using a vacuum brake bleeder can be significant. According to recent industry reports, about 70% of brake-related issues are linked to air in the system. Using this tool can help prevent those problems and ensure proper brake functionality. Many mechanics appreciate the cleaner process. Traditional methods often lead to messy brake fluid spills. The vacuum system minimizes this risk, making for a safer workplace.

While vacuum brake bleeders offer great advantages, they do have limitations. Incorrect usage may result in incomplete fluid extraction. Some users might struggle with the device setup, leading to frustration. Despite these challenges, the overall efficiency gained in time and effort can outweigh the drawbacks. A thorough understanding of the vacuum bleeder can enhance its benefits, ultimately improving vehicle safety.

The vacuum brake bleeder offers significant improvements in automotive maintenance. With an average time savings of 20 minutes during brake flushing, an impressive 90% fluid efficiency, and a user-friendly experience rated at 8 out of 10, it drastically reduces the maintenance frequency to every 6 months.

Vacuum brake bleeders are essential tools in vehicle maintenance. They help remove air from hydraulic brake systems. The bleeding process is important for enhancing brake performance. Key technical specifications for vacuum bleeders typically include a vacuum range of 20 to 30 inches of mercury (inHg). This range ensures effective removal of air bubbles from brake lines.

Industry standards suggest that vacuum bleeders should operate with a minimum flow rate of 10 to 15 fluid ounces per minute. This rate is crucial for ensuring efficiency during the bleeding process. The materials used in construction also matter. Durable and chemically resistant materials can enhance the longevity of the bleeder. Reports indicate that, on average, a properly maintained bleeder can last several years, depending on usage.

However, not all vacuum brake bleeders are created equal. Some may not reach the necessary vacuum level consistently. Inadequate performance can lead to incomplete bleeding. This can cause air pockets to remain in the system, affecting brake responsiveness. Users need to choose tools wisely and regularly check their performance. Understanding these technical aspects is vital for effective vehicle maintenance.

Vacuum brake bleeding systems are popular in automotive maintenance. They work by creating a vacuum, which allows air to be drawn out of the brake lines. This method is straightforward and efficient. It prevents air bubbles, ensuring consistent brake pressure. Many mechanics prefer this system over traditional methods.

Common applications for vacuum brake bleeding include regular vehicle maintenance and emergency situations. It can be especially useful for vehicles with complex brake systems. However, there are limitations. It may not perform well on older cars. In such systems, debris can clog lines, leading to ineffective bleeding. Furthermore, the vacuum method often requires a skilled operator. Improper use can result in residual air in the lines.

Professionals must consider these factors. Each vehicle presents unique challenges. For example, some setups may require additional tools. The vacuum bleeder might not reach all brake lines equally. Regular checks post-bleeding are essential. Relying solely on technology can lead to oversight. In brake maintenance, every detail matters greatly.

| Dimension | Description |

|---|---|

| Functionality | Uses vacuum pressure to remove air bubbles from brake lines. |

| Common Applications | Automobile maintenance, motorcycle repairs, and hydraulic system servicing. |

| Advantages | Quick and efficient bleeding process, minimal mess, and ease of use. |

| Limitations | Not effective for systems with severe contamination, and requires consistent vacuum maintenance. |

| Safety Considerations | Proper handling of brake fluid is essential; always wear appropriate protective equipment. |

| DIY or Professional? | Both DIY enthusiasts and professionals can benefit, although beginners should seek guidance. |