+86-13516964051

+86-13516964051

In the world of metalworking, effective casting equipment is crucial for success. According to recent industry reports, the global market for casting equipment is projected to reach $30 billion by 2026. This growth reflects the rising demand for precision and durability in metal products. Thus, understanding the right tools can significantly impact project outcomes.

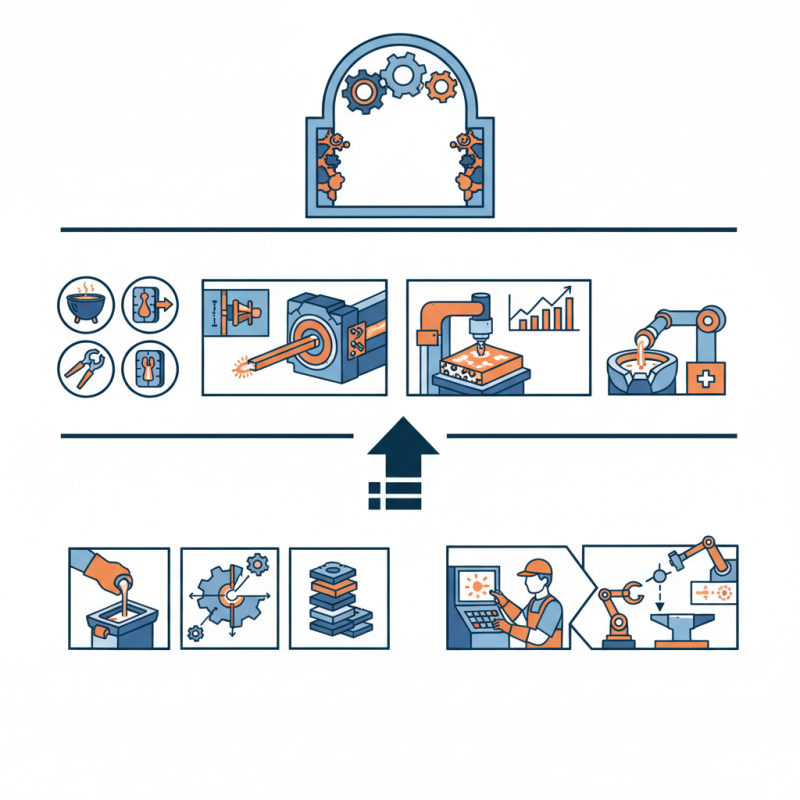

Many metalworkers still overlook essential casting equipment, risking project failures. Basic tools such as furnaces and molds are fundamental. However, advanced tools like induction heaters and CNC machines are often ignored. Studies show that projects using updated casting technology achieve a 25% increase in efficiency. This highlights the need for continuous adaptation in methods.

Castings can be complex, with varying requirements depending on the metal type. Embracing modern casting equipment leads to improvements, yet many professionals remain hesitant. Familiarity with traditional methods sometimes blinds them to innovative solutions. Balancing historical techniques with new technology can be challenging but is vital for staying competitive. The commitment to using the right casting equipment shapes the future of metalworking projects.

In metalworking, having the right equipment is crucial for successful casting projects. Essential tools can greatly influence the quality of your output. An industry report from the Metal Casting Association highlights that nearly 70% of casting issues arise from inadequate equipment or improper setup. This statistic emphasizes the need for precision tools.

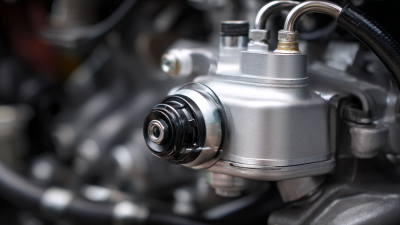

High-quality crucibles are foundational for melting metals. Their construction affects heat retention and distribution, impacting the final product. A poorly designed crucible can lead to inconsistent castings. Additionally, investing in a reliable casting furnace ensures that temperatures remain stable. A report noted that fluctuating temperatures can lead to defects, such as air pockets and weak spots.

Molds play a significant role as well. They should be designed to withstand high temperatures without deforming. However, many hobbyists overlook proper mold maintenance. Regular inspections can help catch wear and tear early, preventing costly mistakes. It's not uncommon for new metalworkers to prioritize tooling over maintenance. Balancing both is essential for long-term success in the craft.

When diving into metalworking projects, it's essential to understand the casting tools you need. Each tool plays a significant role in the overall process. For instance, a well-designed mold captures the shape you desire. A high-quality furnace allows for consistent melting of metals. Without these, your project may falter at the start.

Tips: Always inspect your tools regularly. Ensuring they are in good condition can save time and effort. If a mold is damaged, it could ruin the entire casting batch.

Another important tool is the pouring platform. It helps control metal flow. A poorly designed platform can lead to spills or uneven distribution. Measuring tools are also crucial. Accurate measurements can prevent costly mistakes in your design.

Tips: Don’t rush through measurements. Take your time. Small errors can lead to significant issues later. Continuous practice and adjustment are key to mastering your tools in metalworking.

| Casting Tool | Description | Primary Use | Material Compatibility | Cost Range |

|---|---|---|---|---|

| Furnace | Used for melting metal to a liquid state. | Melting and pouring metal. | Aluminum, Copper, Bronze | $500 - $2000 |

| Molds | Hollow shapes used to give form to the molten metal. | Casting various shapes and sizes. | Steel, Iron, Resin | $50 - $800 |

| Crucible | Container for melting metal. | Holding molten metal during casting. | Ceramic, Graphite | $20 - $300 |

| Pouring Tools | Tools for directing molten metal into molds. | Pouring precision when casting. | Generic, adaptable for various materials. | $10 - $200 |

| Safety Gear | Protective equipment for the metalworker. | Safety during operation. | Universal, essential for all materials. | $50 - $500 |

| Chisels and Files | Tools for finishing touches and corrections. | Shaping and refining cast parts. | Metal, any cast material. | $10 - $100 |

| Tongs | Used to handle hot materials safely. | Moving hot metal. | General use, various materials. | $15 - $150 |

| Heat Treatment Tools | Tools for altering the properties of metals. | Strengthening metal structures. | Various metal types. | $200 - $2000 |

| Melting Assistance Tools | Includes blowers and fans for efficient melting. | Enhancing melting efficiency. | Variety of metals. | $25 - $500 |

Choosing the right casting equipment is crucial for successful metalworking projects. Look for durability when selecting equipment. Quality materials ensure your tools last longer. Lightweight options can also reduce fatigue during long casting sessions.

The size of the equipment matters. Make sure it fits your workspace and your specific needs. Consider portability if you plan to move it often. Additionally, pay attention to safety features, especially when working with high temperatures. An effective cooling system may prevent accidents.

Ease of use is another critical feature. If the equipment is too complicated, it can lead to frustration. Sometimes, it's better to choose basic tools to avoid overwhelming yourself. Don’t ignore the learning curve. Every tool has its quirks, and mastering them takes time. Embrace those moments of imperfection. They often lead to the best improvements.

When working with metal casting tools, safety is paramount. According to the Occupational Safety and Health Administration (OSHA), metal casting can expose workers to high temperatures and toxic fumes. Proper safety gear is essential. Always wear heat-resistant gloves and goggles. A face shield can protect you from splashes and flying debris.

Tips: Keep a fire extinguisher nearby. It's better to be safe. Ensure your workspace is well-ventilated to minimize inhalation of harmful vapors. Hot metal can cause severe burns. Never work alone when handling materials. Having a partner can save lives.

Pay attention to your surroundings. Working in clutter can lead to accidents. Make sure tools are stored properly. The National Safety Council highlights that most workplace injuries occur in areas with disorganized equipment. This can create hazards you might overlook. Always inspect tools before use. A faulty tool may lead to injury or project failure, so don’t skip this step.

Maintaining casting equipment is crucial for any metalworking project. Routines matter. Clean your equipment after each use. Dust and debris can decrease efficiency. Regular cleaning prevents rust. Check for wear and tear weekly. A small crack can lead to bigger issues.

Lubrication is key. Use appropriate oils on moving parts. This minimizes friction and prolongs the equipment's lifespan. Don’t overlook storage. Keep your equipment in a dry space. Humidity can damage metal tools. Inspect storage conditions often. A little moisture can be harmful.

Adjustments are sometimes needed. Ensure parts fit tightly. Loose elements can cause inaccuracies in casting. Also, keep up with training. Not all users know best practices. Develop skills gradually. Mistakes occur, but each one offers a lesson. Regular inspections help identify problems before they escalate.