+86-13516964051

+86-13516964051

Gravity casting has emerged as a pivotal technique in modern manufacturing, particularly in the aerospace and automotive industries. According to a 2021 report by the Global Casting Market, the demand for gravity casting processes has increased significantly, estimated to reach a market size of over $15 billion by 2025. This growth is attributed to gravity casting's ability to produce high-quality, intricate parts with excellent dimensional accuracy.

However, mastering gravity casting techniques requires an understanding of various factors. The choice of materials, for instance, plays a crucial role in the final product's quality. A study by the American Foundry Society indicated that using the right alloys can enhance mechanical properties, leading to better performance in applications. Yet, achieving consistency remains a challenge. Many manufacturers struggle with defects such as porosity or inclusions, highlighting the need for ongoing experimentation and feedback loops in the casting process.

Moreover, the importance of proper temperature control and mold design cannot be overstated. Research shows that slight variations can lead to significant defects. Continuous improvement is vital, and many professionals acknowledge areas needing reflection and refinement. Only through dedication to mastering gravity casting techniques can engineers unlock its full potential and drive innovation in their sectors.

Gravity casting is a widely used method in engineering. It relies on gravitational force to fill molds with molten metal. This technique is popular due to its simplicity and efficiency. The process can produce large metal components with a uniform density.

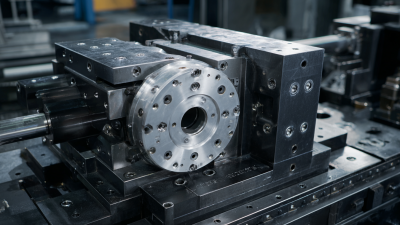

In gravity casting, the design of the mold is crucial. Molds must withstand high temperatures and pressure from the molten metal. Many engineers overlook this aspect. Poorly designed molds can lead to defects. These defects include voids and misalignments, which compromise the final product.

Moreover, understanding the metallurgy involved is essential. Different metals behave differently when cast. For instance, aluminum has a lower melting point than iron. This fact can affect cooling rates and ultimately the integrity of the casting. Sometimes, it takes multiple attempts to achieve the desired quality. Learning from these experiences improves skills over time.

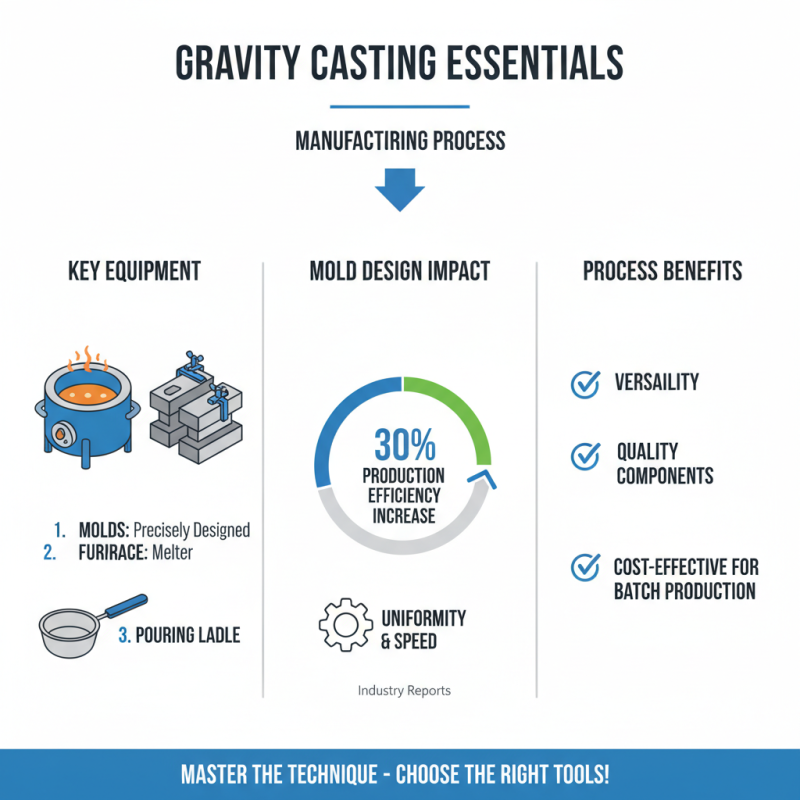

Gravity casting is a popular method in various manufacturing processes, especially in metal casting. To master these techniques, one must have the right tools and equipment. Essential tools include molds, furnace, and pouring ladles. Molds should be precisely designed to ensure uniformity in production. Industry reports show that a well-designed mold can increase production efficiency by up to 30%.

The furnace is critical for melting operations. A gas or electric furnace can achieve the required temperature efficiently. According to a study, maintaining a consistent temperature can reduce defects in cast products by approximately 25%. Proper ladles are also essential for safe and precise pouring. They should be insulated to prevent heat loss during transfer.

While having the right tools is vital, one must also consider safety measures. Inadequate protective gear can lead to serious injuries. Many reports highlighted safety incidents due to negligence in using proper equipment. Continuous training and adherence to safety protocols are crucial. The right setup not only boosts productivity but also ensures a safer workplace for all involved.

Preparing molds for gravity casting is essential for achieving high-quality results. Start with the right materials. You can use sand, clay, or metal to create your mold. Each material has its pros and cons. For durability, metal is ideal, but sand is easier for beginners.

Once you've chosen your material, think about the mold design. It must reflect the object accurately. A slight error can lead to issues later. Begin shaping the mold, paying attention to details. It’s crucial to ensure there are no air pockets. Air bubbles can compromise the casting's integrity.

After shaping, the mold should be smooth. Rough edges may affect the final product’s finish. Check your work carefully. It might not be perfect, but practice helps. You will encounter challenges. Learn from each session. Adjust as needed. Every attempt brings you closer to mastery.

| Step | Action | Materials Needed | Key Tips |

|---|---|---|---|

| 1 | Select your mold design | Design software, mold material | Consider complexity and detail of design |

| 2 | Prepare the mold | Release agent, mold material | Ensure a clean and smooth surface |

| 3 | Mix casting material | Metal alloy, mixing container, stirrer | Follow mixing instructions carefully |

| 4 | Pour the molten material | Safety gear, pouring tools | Pour steadily to avoid spills |

| 5 | Allow to cool | Cooling area | Check temperature guidelines for material |

| 6 | Demold the casting | Tools for demolding | Be gentle to avoid damage |

| 7 | Finishing touches | Sanding, polishing tools | Focus on smoothness and appearance |

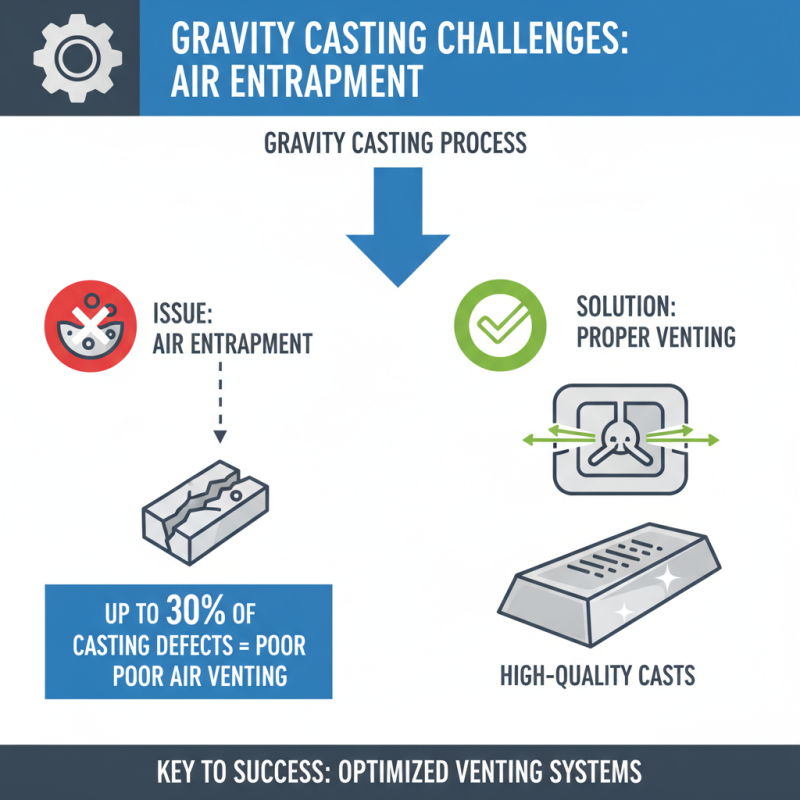

Gravity casting presents unique challenges that can hinder the casting process. One major issue is air entrapment, which can lead to defects in the final product. In a recent study, it was reported that up to 30% of casting defects are linked to poor air venting systems. Proper venting is crucial for achieving high-quality casts.

Here are some useful tips: Ensure that your mold design includes sufficient venting channels. This helps in minimizing air pockets. Additionally, using a reliable release agent can improve the flow of materials and reduce the likelihood of defects.

Another common challenge is achieving uniform cooling rates. When cooling is uneven, it can cause warping or cracking. Industry data indicates that 25% of casting failures relate to inadequate cooling techniques. Monitoring the cooling temperature and applying controlled cooling methods can mitigate these issues.

Remember this tip: Experiment with different cooling rates during the casting process. This trial and error approach can lead to better results. Reflect on your past processes to identify where inconsistencies arise. Continuous improvement is key to mastering gravity casting techniques.

Gravity casting is a popular method for producing metal components. However, maintaining industry standards is crucial. Quality control measures ensure that the final product meets the required specifications.

One key aspect of quality control is the examination of raw materials. Not all metals are created equal. Choosing the right alloy can significantly affect the casting's strength and durability. Regular checks during the melting process are essential. Inconsistent temperatures can lead to defects. It’s a common error to overlook these steps in the rush to produce.

Another consideration is mold maintenance. Molds should be regularly inspected for wear and tear. A worn mold can produce faulty components, resulting in waste. Furthermore, testing the final product is vital. Many forget to conduct thorough inspections. Simple visual checks may not reveal internal flaws. Investing time in these areas can improve overall quality. This reflection on past mistakes helps create a more robust production process.

This chart illustrates the importance of various factors in mastering gravity casting techniques. Each factor is rated on a scale from 1 to 10, with 'Mold Quality' being deemed the most critical component, followed closely by 'Alloy Composition' and 'Quality Control' measures.