+86-13516964051

+86-13516964051

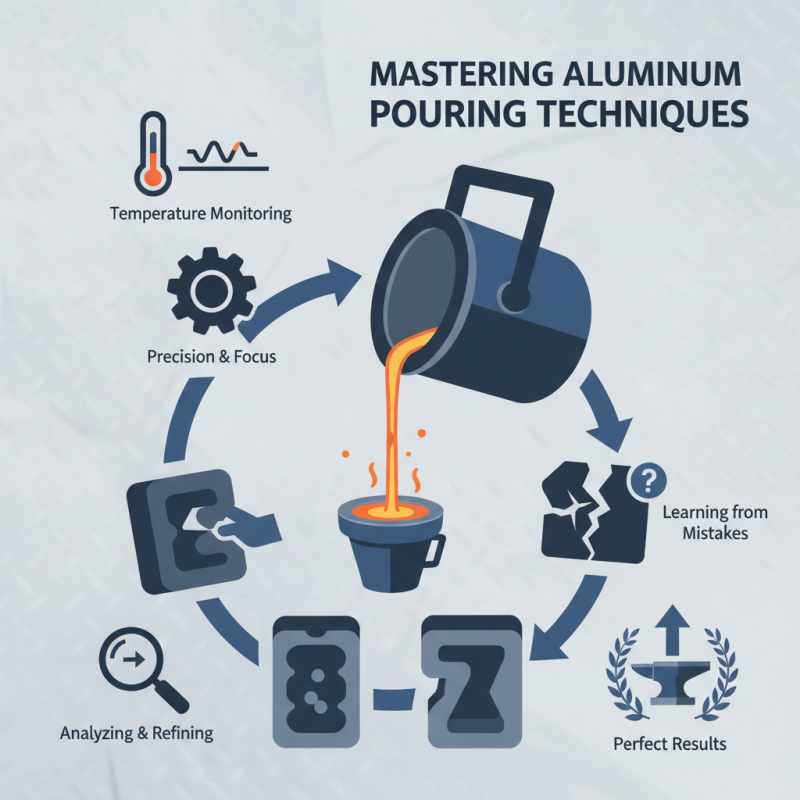

In the world of metal casting, mastering Aluminum Pouring techniques is crucial for achieving optimal results. Renowned expert John Smith once stated, "Precision in Aluminum Pouring transforms visions into reality." This statement captures the essence of what it means to pour aluminum effectively.

Aluminum Pouring requires focus and practice. The process may seem straightforward, but it involves nuances that can trip up even experienced artisans. One must carefully monitor the temperature, as overheating can lead to oxidation. Each pour holds the potential for both success and error, making attention to detail paramount.

Learning from mistakes is part of the journey. Sometimes, a pour may not meet expectations, leading to a need for reflection. By analyzing what went wrong, practitioners can refine their techniques. Perfecting Aluminum Pouring is a gradual process. With dedication, anyone can achieve the desired results.

Understanding the fundamentals of aluminum pouring is crucial for achieving successful outcomes. It begins with the right preparation. Always wear safety gear, including gloves and goggles. Heat shields are essential to protect your skin from burns. The melting point of aluminum is over 1200°F. Always work in a well-ventilated area to avoid harmful fumes.

Proper mold preparation is equally important. Ensure your molds are clean and dry. Any moisture can cause dangerous steam explosions. It might be tempting to rush the process, but patience is key. Pouring too quickly can lead to defects in the final product. Take your time to achieve even flows.

After pouring, inspect the results. Look for air bubbles or rough surfaces. Accepting imperfections is part of the learning process. Each pour reveals new lessons. Reflect on what went wrong and how to improve for next time. Mastering aluminum pouring takes practice and attention to detail. Embrace the journey of refining your technique.

This chart illustrates the efficiency of various aluminum pouring techniques across different temperatures. The data presents the average pour success rate (%) at specified temperature ranges (°C).

When mastering aluminum pouring techniques, the right tools and equipment are essential. A few fundamental items include melting furnaces, pouring ladles, and molds. Each tool plays a vital role in achieving quality results. For instance, a well-designed furnace can significantly impact the uniformity of temperature, which directly affects the pouring process.

Experts highlight the importance of temperature control. According to industry reports, pouring aluminum at the correct temperature can reduce defects by up to 30%. However, many beginners overlook the significance of preheating molds. This can lead to unexpected results, such as cold shuts or incomplete casts. Without proper attention to detail, even experienced pourers may face challenges.

Safety gear is another crucial element. Gloves, goggles, and aprons protect against splashes and high heat. Neglecting personal protection can lead to injuries. Surprisingly, a high percentage of accidents occur during the pouring stage. Investing in reliable equipment is essential, but regular maintenance is equally important. Tools that are worn down or improperly calibrated can result in tarnished finishes or misaligned pieces. Remember, achieving perfection in aluminum pouring is an ongoing learning process.

| Tool/Equipment | Purpose | Material | Tip for Use |

|---|---|---|---|

| Aluminum Melting Furnace | Melting aluminum for pouring | Steel or Cast Iron | Ensure proper ventilation |

| Crucible | Holds molten aluminum | Ceramic or Graphite | Preheat before use |

| Pouring Ladle | Transfers molten aluminum | Metal | Use a steady hand |

| Protective Gear | Ensures safety | Leather, Kevlar | Wear all gear at all times |

| Mold | Shapes the poured aluminum | Sand, Metal | Ensure it's clean and dry |

When preparing melted aluminum, start with safety gear. Wear gloves, goggles, and an apron. These are essential for protection. Aluminum can splash during pouring. A small splash can cause a burn.

Next, gather your materials. You will need a foundry furnace, crucible, and an ingot mold. Check the crucible for cracks. A damaged crucible can lead to failed pours. It's also important to preheat your mold. This prevents the aluminum from cooling too quickly.

Once the aluminum is melted at the right temperature, pour slowly. A steady hand matters. If you pour too fast, you risk creating air bubbles. These bubbles can ruin your final product. Be prepared for minor spills. It happens to everyone. Learn from each pour.

Adjust your technique as needed. The journey to mastering aluminum pouring takes patience. Perfect results come after practice and reflection.

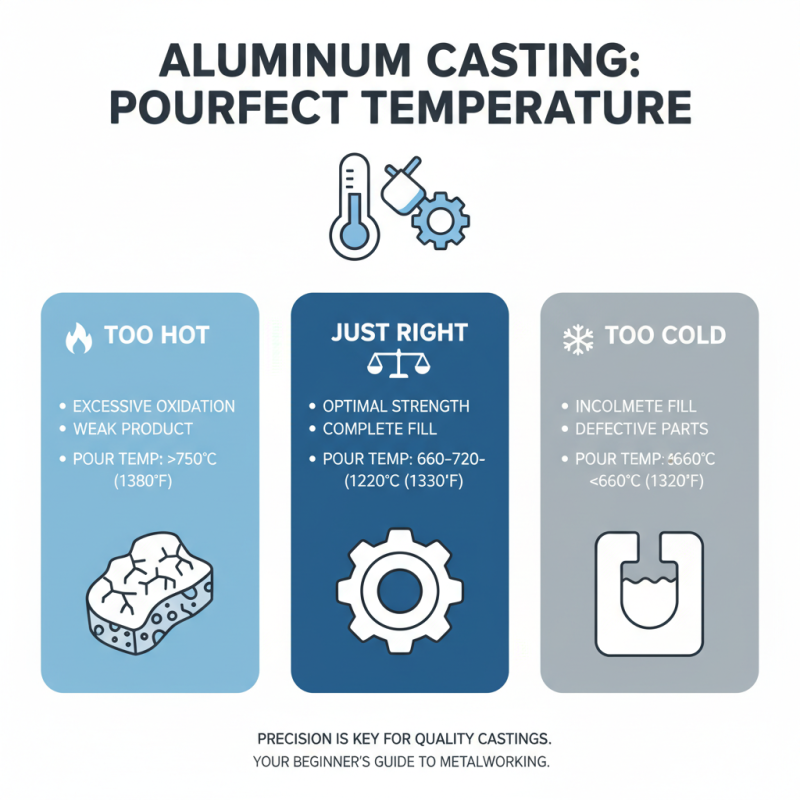

Achieving the perfect aluminum pour requires precision in temperature and consistency. The pouring temperature significantly affects the metal's flow and the final casting quality. If the temperature is too low, aluminum can become difficult to pour. This may lead to defects like cold shuts or insufficient filling in the mold. Conversely, pouring at temperatures that are too high can cause oxidation, which weakens the final product.

Tips for optimal pouring:

1. Use a thermometer: A reliable thermometer can help you maintain the desired pouring temperature range.

2. Monitor your furnace: Regular checks on your heating source can prevent overheating or uneven heating.

3. Pouring consistency is key: Practice makes perfect. Each pour should feel similar in terms of speed and flow.

It’s essential to remember that each casting project can be unique. Different molds may require adjustments in temperature. Sometimes, the first pour doesn’t yield perfect results. Reflecting on what went wrong can guide future attempts. Experimenting with different pouring techniques can help uncover valuable insights. Re-evaluating your method can be the difference between success and failure.

Aluminum casting requires precision. Many beginners face issues that lead to poor results. One common mistake is improper temperature control. Pouring aluminum that is too hot may cause excessive oxidation. This can weaken the final product. On the other hand, pouring at lower temperatures can lead to incomplete filling. It's essential to find the right balance.

Another frequent error is overlooking mold preparation. A dirty or wet mold can disrupt the casting process. Residue may affect the aluminum's adherence to the mold surface. Always ensure the mold is clean and dry before pouring. Regularly inspect your tools and materials to avoid surprises.

Failing to use proper pouring techniques can also lead to defects. Pouring too quickly can create turbulence. This turbulence may trap air bubbles within the cast. Instead, practice a steady, controlled pour. Remember, mastering these techniques takes time and practice. Each mistake offers a chance to learn and improve your skills in aluminum casting.