+86-13516964051

+86-13516964051

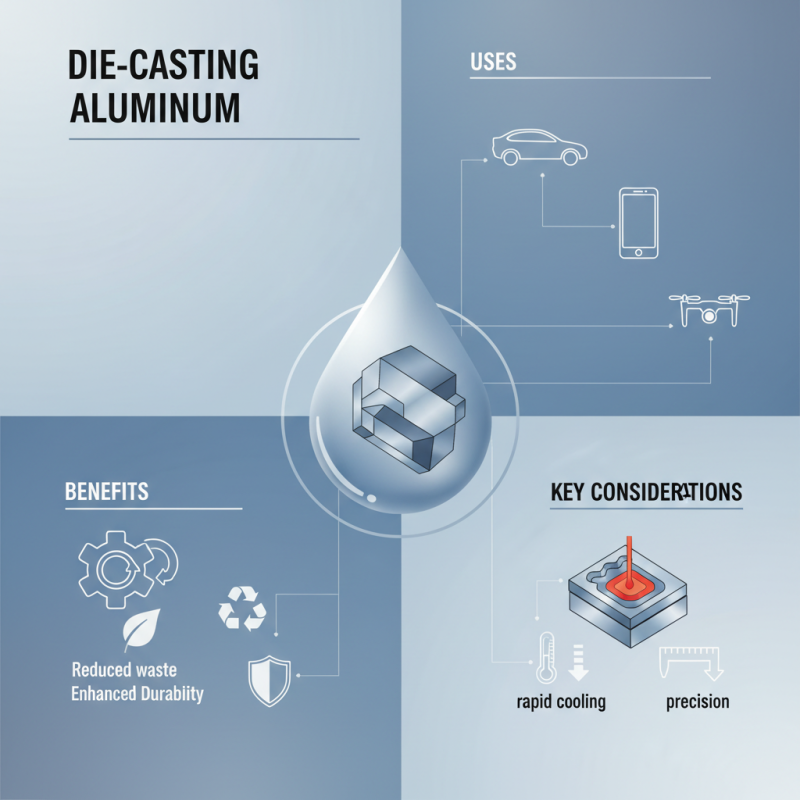

In the realm of metalworking and manufacturing, die-casting aluminum has emerged as a prominent method due to its efficiency and versatility. As noted by renowned expert in the Dies Aluminium industry, Dr. Emily Chen, "The precision and lightweight nature of aluminum make it a perfect material for various applications in die casting." Die-casting aluminum not only allows for complex shapes and high-volume production but also offers significant benefits such as reduced waste and enhanced durability.

This introduction to die-casting aluminum will explore its key advantages, diverse applications, and essential considerations for manufacturers. The process entails injecting molten aluminum into a mold, or die, which leads to rapid cooling and solidification, resulting in high-quality components. Industries ranging from automotive to consumer electronics leverage die-casting aluminum to create critical parts that meet stringent performance and aesthetic standards. Understanding the principles behind dies aluminium can provide valuable insights into optimizing production processes and achieving superior product designs. As we delve deeper into this topic, we'll uncover why die-casting aluminum is a choice that continually influences modern manufacturing practices.

Die-casting aluminum is a manufacturing process that involves forcing molten aluminum alloy into a mold cavity under high pressure. This technique allows for the production of complex shapes with high precision and smooth surface finishes. The process is typically carried out at temperatures around 660°C (1220°F) for aluminum, ensuring that the metal remains fluid enough to fill intricate designs before solidifying.

One of the main advantages of die-casting aluminum is its ability to produce lightweight components that boast strength and durability. This makes it an ideal choice for various industries, including automotive, aerospace, and electronics, where weight reduction and structural integrity are crucial. Additionally, die-casting aluminum components can be produced in high volumes, making it a cost-effective solution for mass production. The quick cycle times associated with this process enable manufacturers to ramp up production efficiently while maintaining quality control throughout.

| Dimension | Details |

|---|---|

| Material Type | Aluminum Alloys (e.g., A380, A383) |

| Process Type | High-Pressure Die Casting |

| Common Applications | Automotive parts, Appliances, Electronics housings |

| Key Benefits | High dimensional accuracy, Complex shapes, Good surface finish |

| Considerations | Initial tooling cost, Limited to non-ferrous metals, Design constraints |

| Environmental Impact | Recyclable material, Energy-intensive process |

Die-casting aluminum is a highly efficient manufacturing process that involves forcing molten aluminum into a metal mold, or die, under pressure. This technique is particularly valued for its ability to produce parts with intricate details and smooth surfaces. The process begins with heating aluminum until it reaches a molten state, after which it is injected into the die. The die is precisely designed to shape the final product, ensuring accuracy and minimizing the need for further machining. Once the aluminum cools and hardens, the die is opened, and the finished part is ejected.

The die-casting process is not only efficient but also offers several advantages. It allows for quick production rates and the ability to produce large volumes of uniform parts, making it ideal for industries like automotive, aerospace, and consumer goods. Additionally, the properties of aluminum, such as its lightweight and corrosion-resistant nature, contribute to the durability of the final products. Key considerations in die-casting aluminum include managing the temperatures of both the aluminum and the die, understanding the lifecycle of the mold, and ensuring the right alloy composition to optimize strength and performance.

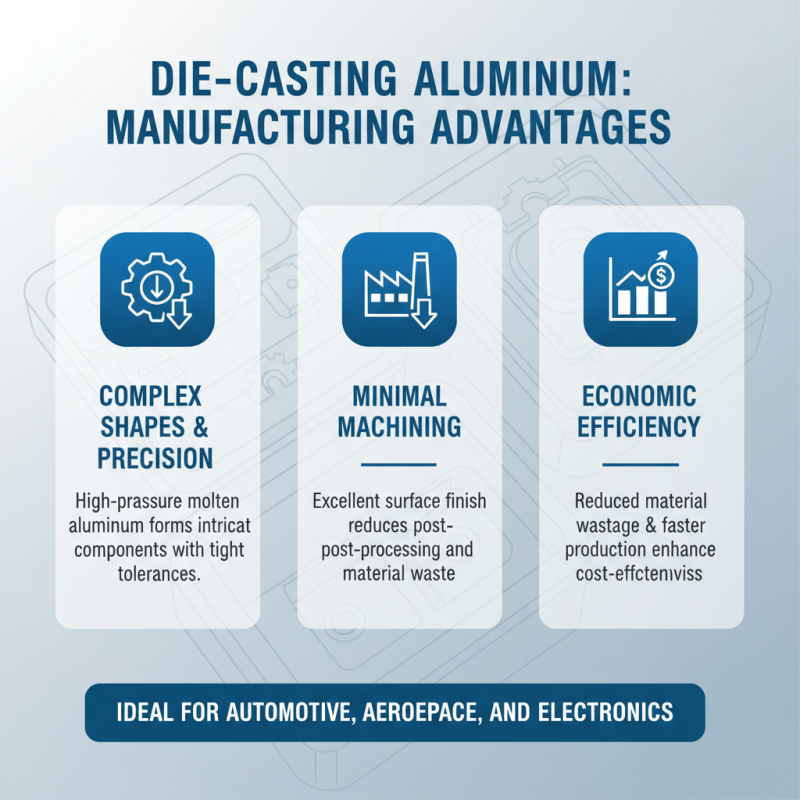

Die-casting aluminum has gained popularity in various manufacturing sectors due to its distinctive advantages. One of the primary benefits is its ability to produce complex shapes with high precision and minimal need for extensive machining. The process involves forcing molten aluminum into a mold under high pressure, which results in components with excellent surface finishes and tight tolerances. This precision reduces material wastage and enhances the overall efficiency of production, making die-casting an economically attractive option for manufacturers.

Additionally, aluminum die-casting components offer a superior strength-to-weight ratio compared to other materials. This characteristic is particularly beneficial in industries such as automotive and aerospace, where reducing weight without sacrificing strength is crucial for improving fuel efficiency and overall performance. Moreover, aluminum is naturally resistant to corrosion, which increases the lifespan of the components and reduces the need for additional surface treatments. As a result, die-casted aluminum parts can contribute significantly to lower maintenance costs and less frequent replacements in high-demand applications, highlighting their long-term economic and practical advantages.

Die-casting aluminum is widely regarded for its versatility and efficiency in producing high-quality metal components. This manufacturing process allows for the creation of intricate shapes with excellent dimensional accuracy, making it ideal for a variety of applications. Common uses of die-cast aluminum parts include automotive components, consumer electronics housings, and industrial machinery parts. According to a recent market analysis, the global die-cast aluminum market is expected to grow at a CAGR of 5.3% through 2026, highlighting its increasing relevance in multiple sectors.

In the automotive industry, die-cast aluminum is often used for engine blocks, transmission cases, and structural components, where strength and lightweight characteristics significantly enhance fuel efficiency. The aerospace sector also benefits from die-cast aluminum due to its high strength-to-weight ratio, promoting energy savings and improved performance in aircraft design. Furthermore, consumer electronics leverage die-casting to create robust and attractive housings that protect delicate internal components while offering aesthetic appeal.

Tips for maximizing the benefits of die-cast aluminum include ensuring proper design considerations, such as wall thickness and draft angles, to facilitate the casting process. Additionally, selecting the right aluminum alloy can significantly impact the mechanical properties of the final product, making it essential to consult with experts during the design phase. By taking these factors into account, manufacturers can achieve optimal performance and cost-efficiency in their die-cast aluminum products.

When considering die-casting aluminum for manufacturing, several key factors come into play. One of the foremost considerations is the material properties of aluminum itself. With a tensile strength ranging from 70 MPa to 350 MPa, aluminum offers a robust profile that suits a variety of applications, from automotive parts to consumer electronics. According to a recent industry report by Grand View Research, the global aluminum die casting market is projected to reach $38.78 billion by 2027, highlighting the demand for lightweight yet durable components across sectors.

Another critical consideration is the cost-effectiveness of die-casting aluminum. The initial setup costs for tooling can be significant, but the high production volumes can lead to reduced per-unit costs in the long run. Industry estimates suggest that die-casting can produce thousands of parts in a single run, making it an economical solution for mass production. Furthermore, the ability to create complex shapes with high precision reduces the need for additional machining processes, further enhancing overall profitability.

Moreover, environmental sustainability is an increasingly important factor in material selection. The recycling rate for aluminum is approximately 75%, making it one of the most recyclable materials in the world. Choosing die-casting aluminum not only aligns with sustainable manufacturing practices but also supports companies in achieving their green initiatives. As industries prioritize eco-friendly approaches, the benefits of die-casting aluminum will likely continue to expand.