+86-13516964051

+86-13516964051

Choosing the right Pressure Die Casting Die is crucial for optimizing your project outcomes. The global die casting market is projected to reach $24.24 billion by 2028, showing significant growth. This growth highlights the importance of selecting the appropriate die for specific applications.

Die casting offers precision and efficiency in producing complex shapes. However, the wrong die choice can lead to costly errors. Studies indicate that over 30% of production costs can arise from die-related issues. Attention to detail is essential; even a slight miscalculation can affect product quality.

Different materials and designs require varied dies. Understanding your project’s specifications is vital. Consider factors such as thermal conductivity and lifespan. This will minimize the potential for defects. Companies that invest time in die selection often report improved performance and reduced waste. Take the time to analyze the options thoroughly.

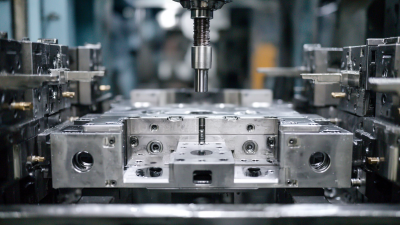

Pressure die casting is a complex process. It involves injecting molten metal into a mold under high pressure. Understanding key concepts can improve your project's success.

The die design plays a crucial role. A well-designed die can increase production efficiency and reduce costs. According to industry reports, improper die design can lead to defects. These defects can increase production time by up to 30%. This is a significant delay in manufacturing schedules.

Material selection impacts the casting's quality. Aluminum and zinc are popular choices due to their lightweight and strength properties. However, using incorrect alloys may result in poor thermal conductivity. This can weaken the final product. Additionally, maintaining the die life is essential. A die can endure around 50,000 cycles under optimal conditions. But wear and tear may reduce this significantly. Thus, regular evaluation is vital for long-term productivity.

Selecting the right pressure die casting die is crucial for the success of your project. Several factors can influence your choice. First, consider the material you plan to use. Different materials have distinct melting points and fluidity. A die suited for aluminum may not work well with zinc. Understanding the characteristics of each material is vital.

Next, think about the complexity of your design. Intricate shapes require dies that can withstand more stress and provide higher precision. A simple shape may not need such detailed engineering. However, opting for a basic design might limit your product’s functionality. Balance is necessary here, and you might find yourself pondering your design choices repeatedly.

Production volume is another factor. If you plan large runs, investing in a high-quality die could be beneficial. Yet, for small batches, this might feel excessive. Reflect on your long-term goals. You may end up overcommitting to a design that doesn’t fit changing project needs. Ultimately, careful consideration is essential to avoid pitfalls.

Choosing the right die for pressure die casting is crucial. Material compatibility plays a key role here. Not all materials suit every die casting process. Understanding the properties of your chosen material is essential. It affects strength, durability, and appearance.

For example, aluminum offers great fluidity. It works well with various die materials. However, magnesium can be trickier. It requires precise control during casting. The wrong die could lead to defects. It limits the functionality of your final product. Knowing these nuances is vital for success.

Scrutinizing the material-die compatibility means examining factors like thermal conductivity and resistance. A mismatch can lead to issues like warping or cracking. Testing various combinations might be necessary. Reflection on past projects can guide decisions. Each choice shapes your results deeply. Always question if the die truly supports your project's needs.

When selecting the right die casting die, complexity is a critical factor. Complex designs often require intricate details and features. Think about the specifications required for your project. You may need a die with multiple cavities or specific cooling channels. The right design can significantly impact production efficiency.

Consider the challenges that may arise. A highly complex die might increase production costs and time. Unexpected issues can surface during the casting process. Ensure your team is prepared for these potential challenges. Simulations can help visualize the end product and identify issues early. Don't underestimate the importance of testing prototypes.

Sometimes, less is more. A simpler die design might serve your needs effectively. Weigh the benefits of complexity against production realities. It's a balancing act that requires careful consideration. Regular feedback sessions with your design team can promote insightful changes. Embrace the possibility of redesigning and refining as needed.

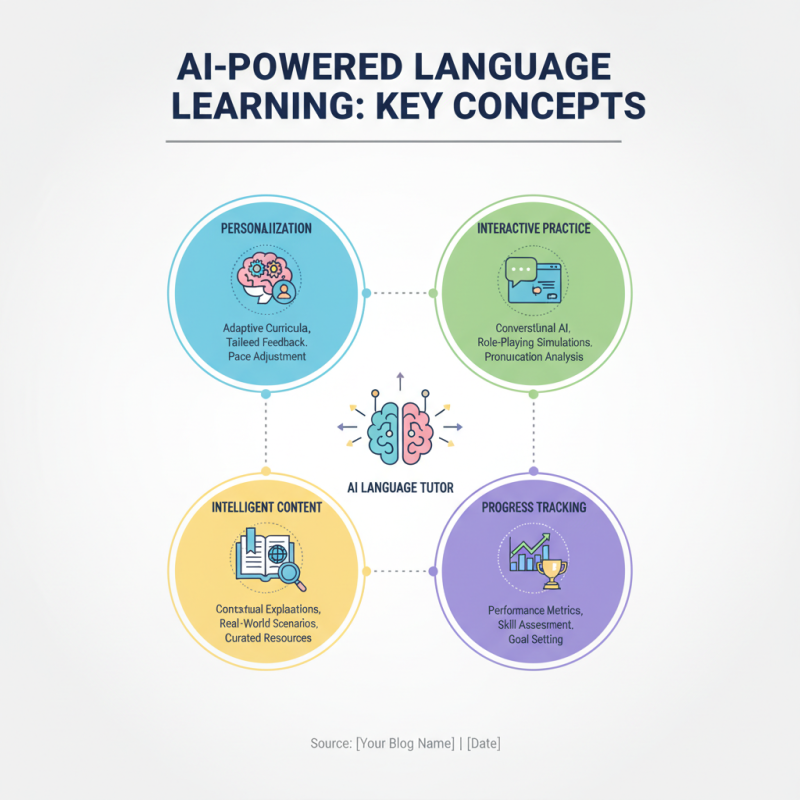

When budgeting for die casting projects, understanding costs is crucial. The die itself is often the largest expense. Complex designs increase costs significantly due to the time required for production. Material choices also influence the budget. Aluminum, for instance, may be cheaper than zinc but can require different tooling and processes.

Labor costs shouldn't be overlooked. Skilled workers are essential for quality results. If the project timeline is tight, prices can rise. Unexpected issues may arise during production. It's wise to set aside a contingency fund. This helps cover delays or design adjustments. Rushing decisions here can lead to overspending or errors.

Consider long-term implications when deciding. A cheaper die might save money initially but could lead to higher maintenance costs. Balancing initial investment with future savings is key. Remember, every project has unique needs. Reflecting periodically on your choices can lead to better budgeting outcomes. Mistakes can teach valuable lessons for future endeavors.

| Parameter | Considerations | Estimated Cost (USD) |

|---|---|---|

| Material | Select appropriate alloy (e.g., Aluminum, Zinc) | $1,000 - $5,000 |

| Die Complexity | Assess the design complexity and detailing required | $3,000 - $15,000 |

| Production Volume | Estimate expected production quantity | $2,000 - $10,000 |

| Lead Time | Consider the time frame required for die fabrication | $1,500 - $4,000 |

| Finish Requirements | Determine surface finish specifications | $500 - $3,000 |

| Assembly Needs | Assess any additional component requirements for assembly | $1,000 - $7,000 |