+86-13516964051

+86-13516964051

In the rapidly evolving landscape of manufacturing, the significance of choosing high-quality Aluminum Die Casting Parts cannot be overstated. According to the "Global Aluminum Die Casting Market Report," the industry is projected to reach a valuation of $18 billion by 2025, driven by the growing demand for lightweight and durable materials in automotive and aerospace applications. With advancements in technology, the capabilities of aluminum die casting are expanding, offering enhanced precision and efficiency that cater to a variety of project requirements.

Expert insights underline the critical nature of selecting the right aluminum die casting parts for successful project outcomes. Dr. Emily Zhang, a leading authority in the field, emphasizes, “The precision and quality of aluminum die casting parts directly impact not only performance but also the overall lifecycle of the product.” This statement echoes the importance of understanding the various factors that contribute to the quality of die cast components, including material selection, design considerations, and manufacturing techniques. As industries look toward sustainable practices, the role of aluminum die casting continues to grow, making it imperative for engineers and project managers to make informed choices tailored to their specific needs.

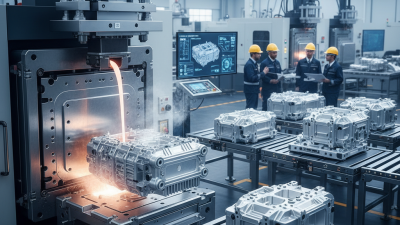

Aluminum die casting is a manufacturing process that utilizes molten aluminum to produce intricate and lightweight parts widely used across various industries. By introducing aluminum into a die at high pressure, manufacturers can achieve high dimensional accuracy and a superior surface finish, making it ideal for applications in automotive, aerospace, and consumer electronics. According to a recent industry report by Smithers Pira, the global market for die casting is projected to grow at a CAGR of 5.5% over the next five years, emphasizing the increasing reliance on aluminum components due to their strength-to-weight ratio and corrosion resistance.

The applications of aluminum die casting are diverse, from complex engine components in vehicles to structural parts in aircraft. For instance, in the automotive sector, light-weighting is critical for improving fuel efficiency, and aluminum die casting allows for the creation of complex geometries that contribute to overall vehicle performance. The American Foundry Society indicates that the automotive industry alone accounts for approximately 40% of the total die casting market, showcasing the significance of this manufacturing method in supporting advancements in fuel-efficient and high-performance vehicles. As more industries adopt aluminum die casting, understanding its capabilities will be crucial for designers and engineers looking to optimize their projects effectively.

When selecting aluminum die casting parts for your projects, several key factors must be considered to ensure optimal performance and cost-effectiveness. One crucial aspect is the alloy composition.

Different aluminum alloys, such as A380 and A383, offer various mechanical properties, including strength, ductility, and corrosion resistance. According to the Aluminum Association, components made from A380 exhibit excellent fluidity and can fill complex molds, making them ideal for intricate designs. Understanding the specific requirements of your application will guide you in choosing the appropriate material for the die casting parts.

Another important factor is the quality of the die casting process itself. The manufacturing technique should be evaluated to ensure that it adheres to industry standards. Reports from the Die Casting Industry suggest that the right choice of tooling and processing parameters can affect the quality of the final part significantly.

Key indicators such as surface finish, dimensional accuracy, and structural integrity should be assessed through regular quality checks and adherence to ISO 9001 standards. Investing in a supplier that maintains high-quality assurance practices can greatly enhance the reliability and performance of the aluminum die casting parts in your projects.

When evaluating the quality of aluminum die casting parts for your projects, several key factors must be considered to ensure optimal performance and durability. First and foremost, assess the dimensional accuracy of the castings. High-quality die casting should exhibit precise measurements and tight tolerances, which are critical for proper fitting and function in assembly processes. Engaging with suppliers that utilize advanced technologies, such as CNC machining post-casting, can enhance accuracy and reduce potential discrepancies in part dimensions.

Additionally, the surface finish of aluminum die casting parts plays a crucial role in their overall quality. A smooth, uniform surface not only improves the aesthetic appeal of the components but also enhances corrosion resistance and minimizes friction during operation. Evaluate the manufacturing processes used to achieve the desired finish, whether it includes polishing, painting, or anodizing treatments. Lastly, inquire about the materials and alloy compositions used in the casting process; the right choice of aluminum alloy can significantly influence the strength, weight, and thermal conductivity of the final product. By comprehensively assessing these aspects, you can make informed decisions that align with your project requirements.

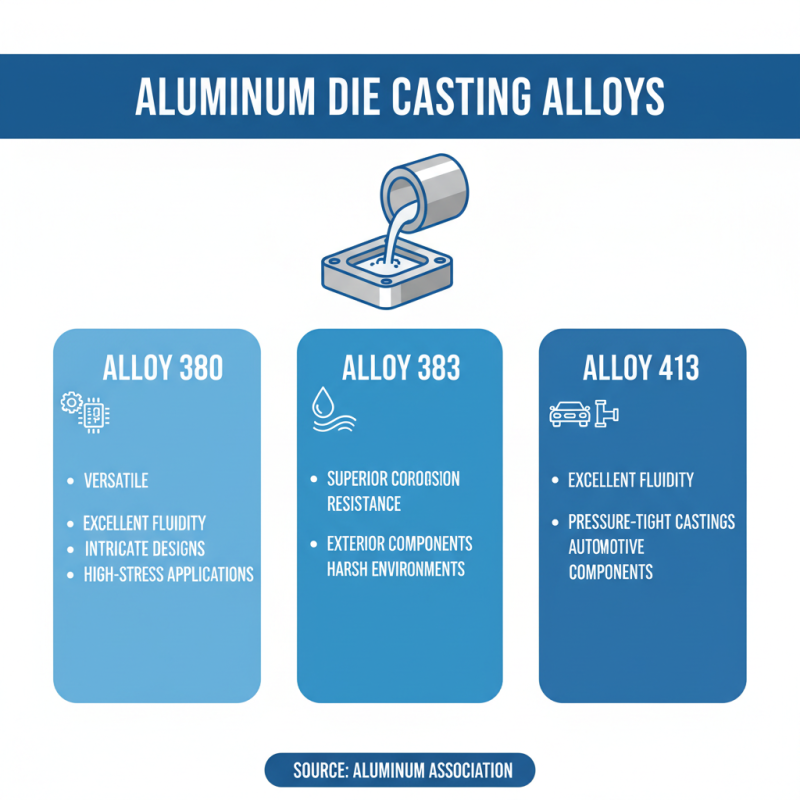

When selecting aluminum alloys for die casting, it is essential to understand the properties of various alloys to ensure compatibility with project requirements. Aluminum die casting commonly employs alloys such as 380, 383, and 413, each offering unique characteristics. According to the Aluminum Association, the 380 alloy is particularly versatile, favored for its excellent fluidity and strength, making it suitable for intricate designs and high-stress applications. Similarly, the 383 alloy, known for its superior corrosion resistance, is ideal for exterior components exposed to harsh environments.

Additionally, alloy 413 is recognized for its high-temperature performance and dimensional stability, which allows for precision in complex parts. Reports from the Die Casting Industry Association indicate that choosing the right alloy can significantly influence the mechanical properties of the final product. For instance, parts made from 380 alloy demonstrate tensile strengths that can reach up to 310 MPa, while 413 alloy can withstand higher operating temperatures, making it valuable in automotive and aerospace applications. Understanding these attributes will aid engineers and designers in making informed decisions that enhance the performance and durability of their die cast parts.

When planning an aluminum die casting project, cost considerations play a crucial role in determining the viability and success of the initiative. An thorough budgeting process begins with evaluating the initial design and production requirements, as these early stages significantly influence overall expenses. It's essential to factor in costs related to mold creation, material procurement, and labor, which can fluctuate based on project specifications. Additionally, unexpected expenses might arise during production; therefore, allocating a contingency budget is prudent to address any unforeseen challenges that may surface.

Moreover, it’s important to analyze the cost-effectiveness of various manufacturing methods and their potential impact on your project's budget. High upfront costs for advanced techniques may lead to long-term savings through increased efficiency and reduced material waste. Conducting a comprehensive cost-benefit analysis will assist in identifying the most suitable options. Engaging with experienced manufacturers can also provide insights into optimizing costs while maintaining quality, ensuring that your aluminum die casting parts meet the required standards within the established budget constraints.