+86-13516964051

+86-13516964051

Choosing the right Pressure Die Casting Die is crucial for production efficiency and product quality. According to a recent industry report by Market Research Future, the global pressure die casting market is expected to grow at a CAGR of 6.2% between 2021 and 2028. This highlights the increasing importance of selecting the appropriate die for specific applications.

Expert John Smith, an engineer with over 20 years in the die casting industry, emphasizes, “The right Pressure Die Casting Die can make or break the manufacturing process.” Understanding the different types of dies and their specifications is essential. Factors like material, design complexity, and production volume play significant roles in decision-making.

However, many manufacturers overlook these details. In some cases, the wrong die can lead to waste and increased costs. The complexity of the design process can be daunting. Improperly selected dies can hinder production and affect product integrity. Investing time in research and consulting industry experts can lead to better outcomes and avoid costly mistakes in the long run.

Pressure die casting is a widely used manufacturing process.

It involves forcing molten metal into a mold under high pressure. This method allows for the creation of

precision parts. The metals often used include aluminum, zinc, and magnesium.

Each material has unique characteristics. These materials influence the final product’s strength and

weight.

Understanding the applications of pressure die casting is crucial. Industries like automotive,

aerospace, and consumer electronics rely on this technique.

It produces complex shapes with excellent surface finish.

However, choosing the right die is not always straightforward. Consider the production volume and

part complexity. A simple design may not require elaborate dies. On the other hand, intricate parts may need more advanced tooling.

Mistakes in die selection can be costly. Sometimes manufacturers overlook the importance of proper cooling.

This can lead to defects in the final product. Additionally, cost constraints might push some to choose cheaper dies.

However, this could compromise quality. Analyzing the design and requirements is essential. A well-thought-out decision can save time and resources in the long run.

When selecting a pressure die casting die, it’s essential to identify specific requirements first. Consider the type of metal you will use. Different materials require different die designs. Aluminum, for example, has unique characteristics that influence the die's structure. Think about the size of the parts, too. Larger components may need more robust dies, influencing cost and production time.

Project goals matter as well. Define your objectives clearly to ensure your die meets those criteria. Adjustments might be needed during the process. It's common to overlook this, resulting in wasted resources. Balancing precision and efficiency can be tricky. A slight miscalculation can lead to significant delays.

Visualizing the end product can help clarify your needs. What will the components look like? Will they be functional right away? Engage with engineers or designers early on. Their insights can shape the die selection process effectively. Remember, flexibility is crucial. Be prepared to re-evaluate your choices as the project evolves.

When considering the right pressure die casting die, it's essential to evaluate the different types available. There are several designs, each tailored for specific applications. For instance, you might find cold chamber and hot chamber dies, each serving unique purposes. Cold chamber dies are ideal for materials with high melting points. Hot chamber dies cater to lower melting point metals, providing efficiency in production speed.

Tips: Always match the die type to your material. This can significantly impact quality. Misalignment could lead to defects. Pay close attention to the surface finish of the die. A well-finished die reduces defects in the final product.

Furthermore, consider the production volume. High-volume needs may demand a robust die design. Conversely, lower volumes may allow for more flexible options. Exploring the die's cooling mechanisms is also crucial. The right cooling design enhances cycle times and improves overall performance. Remember, these choices can directly affect cost and effectiveness. Make sure to reflect on how your needs align with these factors.

Choosing the right pressure die casting die is essential to achieving optimal results in your casting operations. When considering die selection, three major factors come into play: material, design, and costs.

Material selection is crucial. The die material impacts durability, heat resistance, and overall performance. According to industry reports, high-quality steel can last up to 1 million cycles, while lower grades may yield only 200,000 cycles. This difference can significantly affect production timelines and costs.

Design is another pivotal aspect. A well-engineered die can minimize defects and improve production efficiency. Complex geometries may require advanced design methods. However, intricate designs often inflate costs. Balancing detailed design and budget is a common challenge.

Cost is often the deciding factor. Initial die costs may be high, but long-term savings through durability and efficiency can justify the investment. Many experts suggest a total cost of ownership analysis. Yet, companies may overlook this, focusing only on upfront costs. This may lead to missed opportunities for cost-saving over time.

| Factors | Description | Examples |

|---|---|---|

| Material | The type of metal used in die casting that affects durability and application | Aluminum, Zinc, Magnesium |

| Design Complexity | The intricacy of the part design, influencing tooling and production | Thin walls, intricate geometries, surface finishes |

| Production Volume | The expected quantity of parts to be produced, guiding cost-effectiveness | Low volume (<1000), Medium volume (1000-10000), High volume (>10000) |

| Cost | Budget constraints affecting the choice of materials and complexity | Tooling costs, material costs, production costs |

| Lead Time | The timeframe for design approval, tooling creation, and production | Standard (2-4 weeks), Accelerated (1-2 weeks) |

| Post-Processing Needs | Additional operations required after casting to meet specifications | Machining, finishing, assembly |

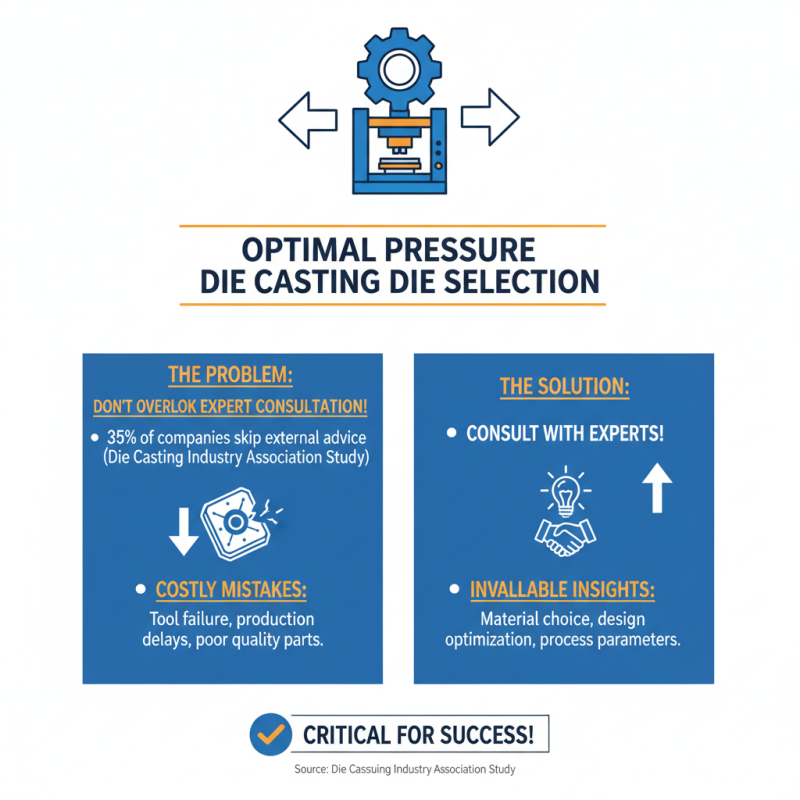

Choosing the right pressure die casting die is critical. Consulting with experts can offer invaluable insights. Many manufacturers overlook this step, leading to costly mistakes. A study by the Die Casting Industry Association revealed that 35% of companies fail to seek external advice when making decisions.

Engaging professionals provides access to experience and knowledge. Experts can help identify project needs. They assess materials, production volume, and design complexity. A recent report indicated that utilizing expert consultation can reduce production issues by 25%. This highlights the importance of their guidance.

Reflections on past decisions reveal gaps in knowledge. Relying solely on internal teams can limit creativity. Sometimes, an outsider's perspective uncovers opportunities for improvement. The die casting process is complex, and navigating it alone can lead to oversights. Embracing expert advice is a step toward enhanced production efficiency.