+86-13516964051

+86-13516964051

Choosing the right metal parts for your project is crucial. Metal parts play a pivotal role in various industries. According to a report by the Metal Service Center Institute, the metal parts industry is projected to grow by 5% annually due to increased demand.

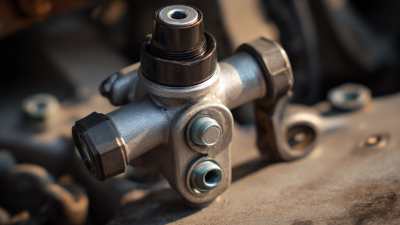

Selecting suitable metal parts can be overwhelming. Multiple factors influence the decision. Material strength, corrosion resistance, and weight are vital considerations. For instance, stainless steel is preferred for its durability in harsh environments. Still, it can be costly compared to aluminum, which is lighter but less durable. Evaluating your project's requirements is essential for making informed choices.

However, not every selection will be perfect. Sometimes, compromises are unavoidable. You may choose a more economical option, but performance may suffer. Reflecting on these choices is necessary for future success. Each decision shapes the overall project outcome, so careful thought is key. Understanding the nuances of metal parts will lead to better results.

When selecting metal parts for a project, start by identifying specific requirements. Consider the function needed. Will the parts undergo stress or wear and tear? Understanding the demands can help you avoid common pitfalls. For instance, using aluminum in a high-stress scenario may lead to failure.

Next, think about the environment where the metal parts will be used. Will there be exposure to moisture, chemicals, or extreme temperatures? Assessing these factors is crucial. A low-cost option might work at first, but long-term reliability is key. You may need to invest more upfront for better durability.

Don’t forget to factor in fabrication methods. Are the metal parts being welded, machined, or cast? Each method has its limitations. Misunderstanding these can lead to oversights. It’s essential to communicate these requirements clearly to avoid costly mistakes later on. Addressing these questions thoroughly can lead to better outcomes for your project.

Choosing the right metal for your project is crucial. Different metals have distinct properties. Understanding these can save you time and money.

Steel is strong and versatile. It resists wear and can handle heavy loads. However, it can rust if not treated. Aluminum is lightweight and corrosion-resistant. It is good for projects needing lower weight. But it may not handle high stress as well as steel.

Copper is excellent for electrical projects. It conducts electricity efficiently. Still, it's softer and prone to wear. Consider your project needs carefully. Researching properties can prevent mistakes. Each metal has strengths and weaknesses, and it’s essential to find the right match.

When selecting metal parts for your project, evaluating cost versus quality is crucial. Quality often dictates performance and lifespan. Higher-quality metals resist wear, corrosion, and deformation over time. They may have a higher upfront cost, but the long-term benefits can offset this. Cheaper options might save money initially. However, they can lead to increased maintenance and replacement costs later on.

Consider the specific demands of your project. If it requires precision and durability, investing in quality parts is wise. In contrast, for projects with less stringent requirements, lower-cost materials may suffice. There is always a risk when prioritizing cost over quality. Lower-grade metals can fail unexpectedly, leading to potential project delays or safety issues. Reflecting on these trade-offs is essential. Ultimately, understanding your project's needs will guide you toward a more informed decision.

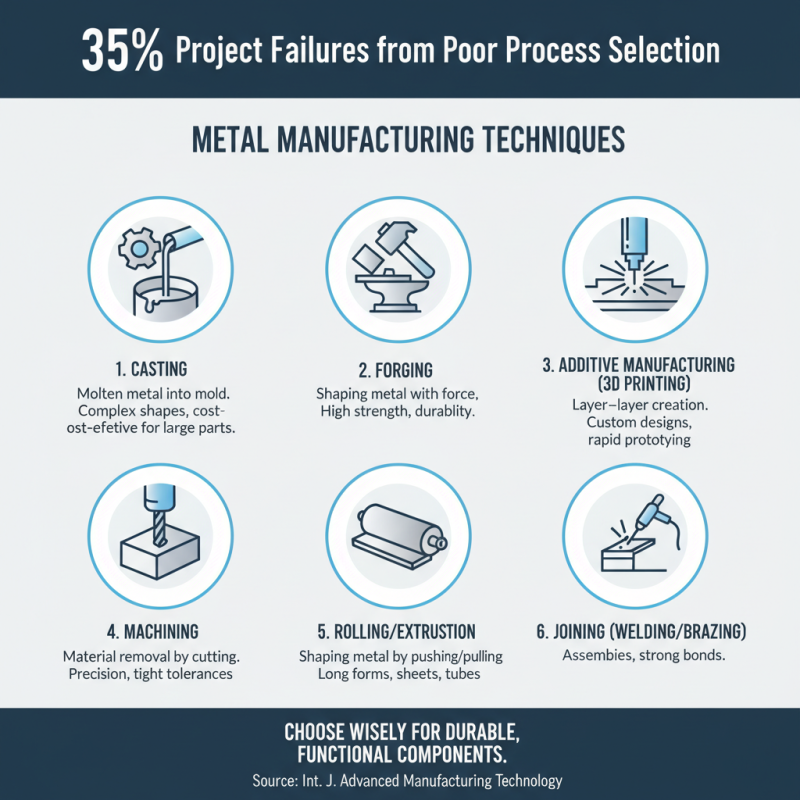

Choosing the right manufacturing technique for metal components can significantly impact your project's success. According to a report from the International Journal of Advanced Manufacturing Technology, nearly 35% of project failures stem from poorly selected materials and manufacturing processes. Understanding various techniques is essential for achieving durability and functionality.

Milling, casting, and 3D printing are common methods, each with advantages and drawbacks. For instance, machining provides tight tolerances, yet it can be costly and time-consuming. Conversely, 3D printing allows for rapid prototyping, but might face challenges in material strength. A study by the American Society for Metals indicates that about 40% of companies struggle with meeting performance requirements due to improper technique choices. Considering these factors early in your planning process is critical.

It's important not to overlook the quality of the raw materials used. A flawed metal can compromise the entire project. Reports suggest that 30% of metal parts tested fall short of industry standards. Therefore, a thorough assessment of both the manufacturing technique and the material quality is vital for any successful project.

Choosing the right metal parts for your project is crucial. Compatibility with other materials can make or break your design. Consider how different materials react together. Some metals corrode when in contact with certain plastics or wood. This can lead to premature failure or increased maintenance costs.

Evaluate the properties of the metals you plan to use. For instance, aluminum is lightweight but may not withstand heavy loads like steel. Think about thermal expansion as well. Metals expand when heated, which can create stress in joints with less stable materials. Test your combinations before finalizing your design.

It's also essential to consider the environment your project will face. Will it be exposed to moisture or varying temperatures? These factors can influence your choice of metal. Beware of the fragility that some combinations can create. Reflect on the potential long-term impacts. Don't rush your decisions; prioritizing compatibility can save you time and resources in the end.