+86-13516964051

+86-13516964051

Choosing the right Metal Casting Machine is crucial for your business's success. A suitable machine can improve efficiency and reduce costs. However, the process can be challenging. There are various models and features to consider.

Different industries require different capabilities. High precision may be vital for aerospace parts. In contrast, automotive industries might need faster production. Understanding these needs is essential. It’s easy to overlook important features that suit your business. A detailed assessment can prevent costly mistakes later.

Investing in the wrong machine is a significant risk. You may waste resources and time. Reflecting on your specific requirements is necessary. What materials will you use? How much production capacity do you need? These questions guide your decision. Making an informed choice ensures that your Metal Casting Machine meets your current and future needs.

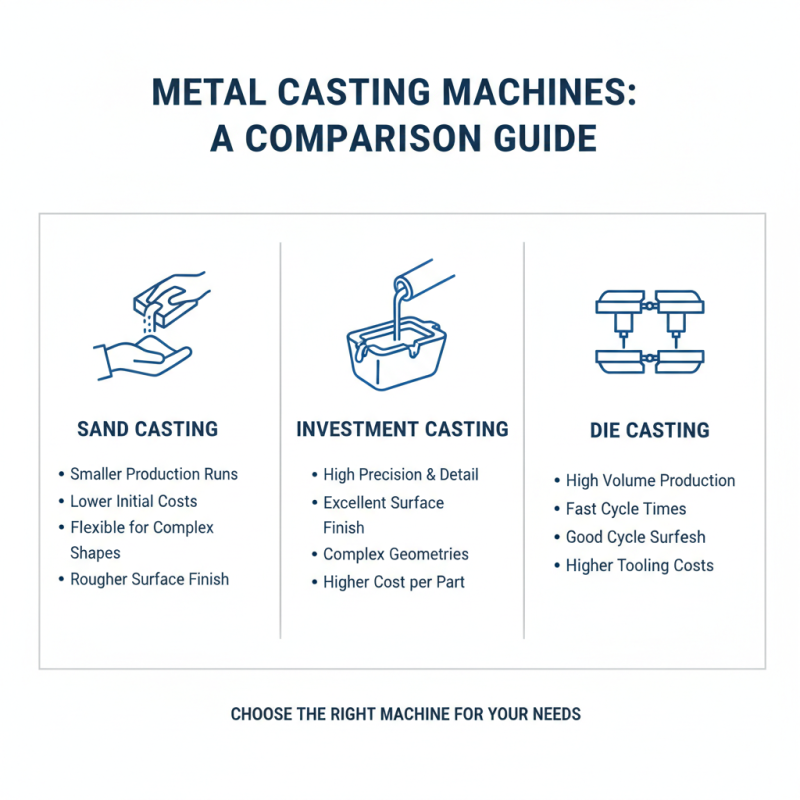

When selecting a metal casting machine, it's essential to understand the variations available. Basic types include sand casting machines, investment casting, and die casting. Each type serves distinct purposes and has unique advantages. For smaller production runs, sand casting machines offer flexibility and lower initial costs. They are suitable for complex shapes. However, the surface finish may not be as refined.

Investment casting machines produce high-precision parts. This method creates detailed designs with excellent surface finishes. It is ideal for intricate components. Yet, the process can be expensive and time-consuming. Evaluate your production needs carefully.

Tip: Consider your output volume. High-volume production might justify investing in die casting machines for speed and efficiency. However, if only a few pieces are required, other options may be more practical.

When choosing, assess the materials you plan to use. Not all machines handle every metal type effectively. Some machines have limitations concerning heat tolerance. Always verify compatibility with your desired metals.

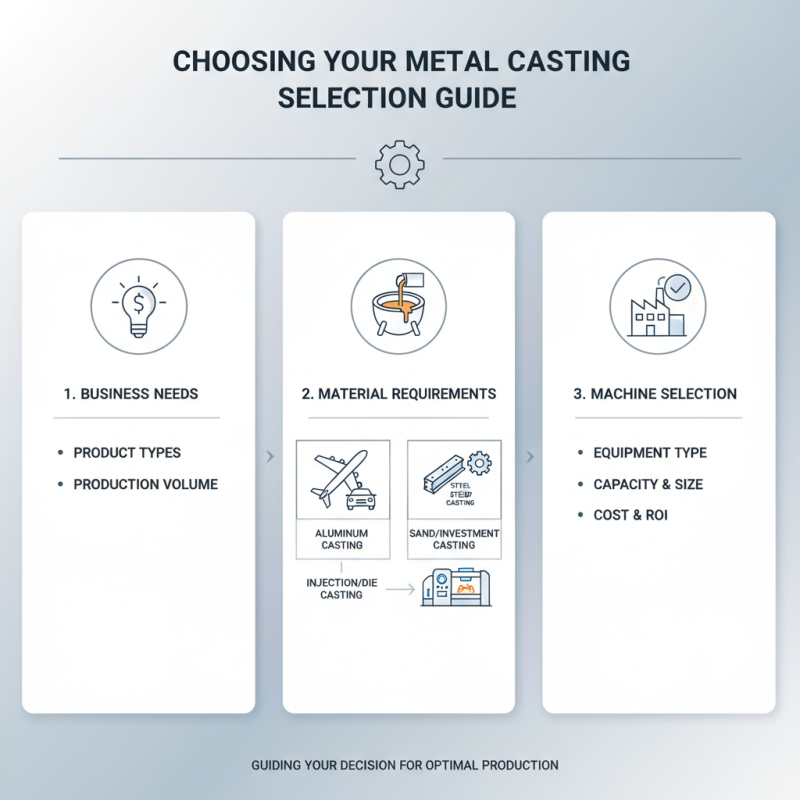

When considering a metal casting machine, understanding your business needs is essential. Start by evaluating the types of products you plan to manufacture. Different projects require machinery tailored for specific materials. For example, aluminum casting demands different machines than steel casting. Assessing your material requirements will guide your decision.

Next, consider production volume. If your business focuses on low-volume, custom parts, a smaller, flexible machine may suffice. However, higher production rates will necessitate more advanced machinery. Look into your budget too. Some machines come with high initial costs but may save money over time. It’s crucial to weigh these factors carefully.

Lastly, don't forget the technical support and maintenance. Poor support can lead to unplanned downtime. Always plan for potential issues. Think about training for your staff as well. A sophisticated machine might require specialized knowledge. Balancing these needs will help you make a well-informed choice.

Choosing the right metal casting machine for your business can be daunting. You must evaluate several key features to make an informed decision. Power and capacity are critical. Consider how much metal you plan to cast at once. Machines vary widely in size and output. Erring on the side of caution can lead to costly delays.

Next, think about the types of molds you'll be using. Some machines work better with specific mold materials. Compatibility matters for achieving quality casts. Additionally, look into the machine’s cooling system. A robust cooling system ensures faster production times. However, it may increase initial costs.

Don’t forget about maintenance. A machine that is easy to maintain can save you time and money in the long run. Not all machines come with clear maintenance guidelines. This can lead to issues later if not addressed. Also, consider the technical support available. Sometimes, machines break down unexpectedly, and you need prompt assistance. Reflecting on these factors will help you find a machine that truly meets your needs.

When considering a metal casting machine, budget is crucial. Assessing costs requires more than just the price tag. Often, hidden expenses can inflate initial costs. Think about maintenance, energy consumption, and operational efficiency. These factors can dramatically affect your bottom line over time.

Price isn't the only concern. Many machines may seem affordable upfront but have high long-term operating costs. Do thorough research to understand each machine's lifecycle. Some might require special facilities or skilled labor, which adds to expenses. You may also face unexpected repair costs that disrupt production.

It's essential to find a balance between quality and cost. Sometimes, the cheapest option isn't the best choice. Investing in a reliable machine could yield better returns. Reflect on your production needs and future growth. A well-thought-out investment now could lead to significant savings later. Remember, making the right choice takes time and careful analysis.

When searching for metal casting machines, it's essential to identify reputable manufacturers and suppliers. Start by conducting online research. Check for reviews and testimonials from other customers. Look for feedback on the quality and durability of machines. High ratings reflect reliability, but be cautious. Some reviews may be biased or fake. Fact-check information from multiple sources.

Attend industry trade shows and events, if possible. Connecting with suppliers face-to-face provides deeper insights. Discuss their products and services. Ask about their manufacturing processes and materials. Reliable manufacturers will share this information confidently. Pictures and demonstrations help visualize machines in action. Pay attention to those details.

Consider reaching out to industry associations for recommendations. They often have insights into trustworthy suppliers. However, it’s crucial to remain vigilant. Even recommended suppliers might not meet expectations. Verify their credentials and past projects. A thorough evaluation can prevent potential pitfalls when investing in metal casting equipment.

| Feature | Description | Importance Level |

|---|---|---|

| Machine Type | Consider the type of casting required (sand casting, die casting, etc.) | High |

| Capacity | Evaluate the production volume needed | High |

| Energy Efficiency | Look for machines that consume less energy | Medium |

| Cost | Analyze the budget for the machine | High |

| Manufacturer Reputation | Research the reliability of manufacturers | High |

| Support and Training | Check if the manufacturer provides training and support | Medium |

| Warranty and Maintenance | Consider warranty duration and maintenance services | Medium |