+86-13516964051

+86-13516964051

When navigating the dynamic landscape of the aluminum casting industry, selecting the right Aluminum Casting Machine is a critical decision that can significantly influence production efficiency and product quality. According to industry expert Dr. James Connors, a renowned metallurgist and consultant, “The right choice of casting machine tailored to specific production needs not only enhances productivity but also optimizes material use and reduces waste.” This underscores the importance of thoroughly understanding one’s requirements before making an investment.

A well-chosen Aluminum Casting Machine can make the difference between a thriving operation and one that struggles to meet demand. Factors such as the type of aluminum alloy, casting volume, and desired detail are crucial to consider. As the technology continues to evolve, staying informed about advancements is essential for manufacturers who wish to remain competitive. By examining the various types of machines available and understanding the specific needs of a business, companies can navigate the selection process with confidence, ensuring they invest in equipment that aligns with their operational goals and capacities.

Aluminum casting machines are essential tools for various industries that require the production of aluminum components. Understanding the basics of these machines is crucial to selecting the right one for your specific needs. At their core, aluminum casting machines are designed to melt aluminum and pour it into molds to create desired shapes. The fundamental processes involved include die casting, sand casting, and investment casting, each offering unique benefits depending on the application.

When choosing an aluminum casting machine, it is important to consider the type of casting process you plan to use. Die casting is ideal for high-volume production because of its efficiency and precision, while sand casting is more suitable for creating larger parts with complex geometries. Additionally, investment casting is preferred for producing high-quality components that require intricate details. Knowing the characteristics and advantages of each casting method can guide you toward the best choice that aligns with your production goals and budget constraints.

When selecting the right aluminum casting machine, the first step is to thoroughly identify your specific casting needs and requirements. Start by assessing the types of aluminum components you plan to produce. Consider factors such as size, weight, and complexity of the designs, as these will dictate the necessary capabilities of the machine. For instance, high-pressure die casting may be essential for intricate geometries, while sand casting might be more suitable for larger, simpler parts. Additionally, evaluate your production volume. Machines vary significantly in their throughput, so understanding your demand will help in choosing equipment that aligns with your operational goals.

Another critical aspect to consider is the level of automation required in your casting process. Automated systems can enhance efficiency and consistency, reducing labor costs and minimizing human error. However, for smaller-scale operations or prototyping, a semi-automated or manual machine might suffice. Furthermore, think about the machine's adaptability for future projects. As industry demands evolve, having a machine that can accommodate a variety of casting methods and materials can be invaluable. By clearly defining your specific production needs, you set a strong foundation for selecting the most suitable aluminum casting machine for your operations.

When selecting the right aluminum casting machine, evaluating key features and specifications is crucial to meet production needs effectively. One of the primary considerations is the machine’s capacity and efficiency. According to a recent industry report by MarketsandMarkets, the aluminum casting market is expected to grow at a CAGR of 5.7% from 2021 to 2026, highlighting the increasing demand for efficient casting processes. A good casting machine should have a throughput that aligns with your production goals while ensuring high-quality output.

In addition to capacity, the type of melting furnace integrated within the casting machine plays a significant role. Induction furnaces are gaining popularity due to their energy efficiency and precise temperature control, making them suitable for high-quality aluminum casting. Research shows that induction furnaces can reduce energy consumption by up to 30% compared to traditional melting methods.

Tips: When choosing a machine, ensure to analyze the features such as automation capabilities and ease of maintenance. A machine with advanced automation can streamline operations and minimize labor costs, while exceptional maintenance support can significantly impact long-term productivity. Evaluate user feedback and seek data-backed operational performance statistics to make an informed decision.

When selecting the right aluminum casting machine, it's essential to understand the different types available in the market. Each type is designed to meet specific production needs and achieve various casting techniques. Common types include gravity die casting machines, pressure die casting machines, and sand casting machines.

Gravity die casting machines utilize the force of gravity to fill molds; they are ideal for simpler shapes and lower production volumes. On the other hand, pressure die casting machines apply pressure to inject aluminum into molds, making them suitable for high-volume production and intricate designs.

Another type worth considering is the sand casting machine, which uses sand as a mold material. This method offers versatility and is often used for larger parts or components that require more complex shapes. Sand casting, while not as rapid as die casting methods, allows for significant customization and can accommodate varied alloy compositions.

Furthermore, modern advancements have led to hybrid machines that combine the benefits of different casting methods, providing greater flexibility and efficiency. By understanding these variations, you can better align your choice of machine with your production goals and material requirements.

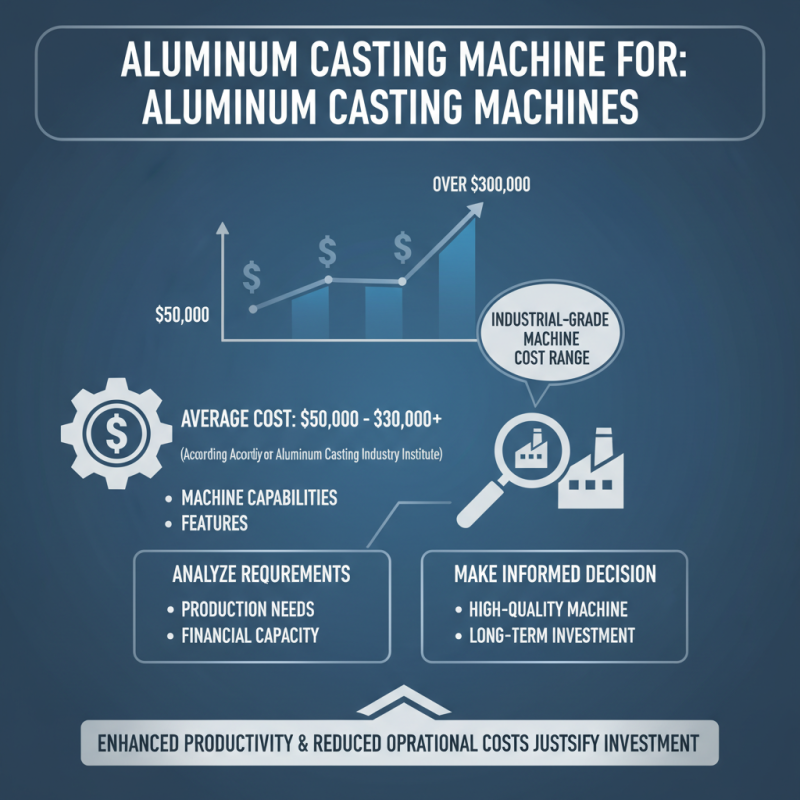

When selecting an aluminum casting machine, budget considerations play a crucial role. According to a recent report by the Aluminum Casting Industry Institute, the average cost of an industrial-grade aluminum casting machine ranges from $50,000 to over $300,000, depending on the machine's capabilities and features. Companies should analyze their production requirements and financial capacity before making a decision. Investing in a high-quality machine is often justified if it significantly enhances productivity and reduces long-term operational costs.

Tips: Prioritize machines that offer a balance between initial cost and operational efficiency. It's prudent to consider the long-term savings that come from energy-efficient models. Additionally, spare parts availability and maintenance costs can impact the overall budget; hence, understanding these factors beforehand can prevent unforeseen expenses down the line.

Another key aspect to consider is the total cost of ownership for the aluminum casting machine. This includes not just the purchase price, but also operational costs, maintenance requirements, and potential downtime impacts. The same report indicates that manufacturers can expect up to 20% of the total machine cost in maintenance over its lifetime. Therefore, conducting a thorough cost-benefit analysis is essential to ensure that the chosen machine aligns with both operational needs and fiscal constraints.