+86-13516964051

+86-13516964051

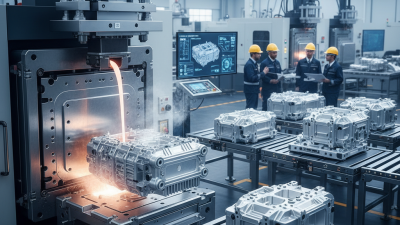

Die casting aluminum parts are pivotal in various industries due to their lightweight, durability, and excellent thermal conductivity. According to a recent market analysis published by Research and Markets, the die casting market is projected to reach $85 billion by 2025, driven largely by the growing demand in automotive and consumer electronics applications. These components not only provide cost-effective solutions but also enhance performance and efficiency, making them an essential choice for manufacturers.

When selecting die casting aluminum parts for your project, one must consider several critical factors that impact both quality and functionality. A comprehensive understanding of the manufacturing process, including the intricacies of mold design and material selection, can significantly influence the final product's performance. The Global Aluminum Die Casting Market Report indicates that advancements in die casting technologies have led to improved precision and reduced cycle times, which are crucial for meeting modern production requirements.

Furthermore, as industries increasingly focus on sustainability, the choice of die casting aluminum parts is further justified. Aluminum is highly recyclable, and using it in die casting not only minimizes waste but also reduces the carbon footprint of production. As you embark on your project, leveraging the benefits of die casting aluminum parts can provide competitive advantages, ensuring that your application stands out in a crowded marketplace.

Die casting is a manufacturing process that involves pouring molten metal into a mold cavity to produce parts with high precision and complex geometries. When it comes to aluminum, die casting is an ideal choice due to its lightweight characteristics, excellent corrosion resistance, and thermal conductivity. This technique allows for the production of intricate shapes that can be used in various applications, from automotive components to consumer electronics. Understanding the fundamentals of die casting is essential for selecting the best aluminum parts for your project.

One of the key advantages of aluminum die casting is its efficiency in mass production. The molds used in die casting can withstand the high pressure and temperature, enabling the creation of consistent and uniform parts with minimal finishing work required. Additionally, die-cast aluminum parts often have a superior surface finish, which can improve the aesthetic appeal and functionality of the final product. As you consider your project requirements, it is crucial to evaluate factors such as weight tolerance, strength, and potential for secondary operations, ensuring that the chosen parts align with the intended application effectively.

When selecting die casting aluminum parts for your project, it’s essential to consider several key factors to ensure optimal performance and quality. First and foremost, assess the design complexity of the parts you require. Die casting allows for intricate shapes and thin-walled designs that can significantly reduce machining time and material waste. Ensure that your designs align with the capabilities of the die casting process to maximize efficiency.

Material purity and alloy selection also play a crucial role in the durability and strength of the cast parts. Different aluminum alloys offer varying characteristics such as corrosion resistance, thermal conductivity, and mechanical strength. Conducting a thorough analysis of the alloy properties in relation to your project's specific requirements will help you choose the best fit.

**Tips:** Always request samples from your supplier to evaluate the quality of the die-cast aluminum parts. This can provide valuable insights into their manufacturing process and the overall finish of the components. Additionally, consider the supplier's experience and reputation in the industry, as a reliable partner can often ensure better quality control and delivery timelines. Furthermore, evaluate the post-processing options available, as machining or surface treatments may be necessary for achieving the desired final result.

When selecting die casting aluminum parts for your project, evaluating the quality and precision of the die casting process is paramount. High-quality die casting results in consistent, reliable parts that meet your specifications. Key factors to consider include the skill and experience of the manufacturer, the technology utilized in the casting process, and the materials used. Quality assurance measures, such as metallurgical testing and dimensional inspection, are essential in ensuring that the final product adheres to the desired standards.

Tips:

Always request samples from potential suppliers to assess their quality firsthand. Look into a manufacturer’s certifications, such as ISO standards, which indicate a commitment to quality management and process consistency. Additionally, do not hesitate to inquire about their production techniques and machinery; advanced technology usually correlates with higher precision in die casting.

Precision in die casting is achieved through careful control of the process parameters. This includes temperature management, cooling rates, and gating systems that influence metal flow. A precise die casting process not only enhances the dimensional accuracy of the parts but also reduces material wastage and post-processing needs.

Choosing a supplier who employs state-of-the-art technology and rigorous testing protocols will significantly contribute to the overall success of your project.

Tips: Engage in discussions with technical experts at the manufacturing facility to understand their approach to maintaining precision. Consider the complexity of your design; intricate features may require specific tooling or casting techniques. Always factor in the potential for tolerances and how they affect the fit and function of the final product.

When selecting die casting aluminum parts for your projects, understanding the costs and benefits associated with different aluminum alloys is crucial. The most commonly used alloys for die casting include A380 and A356, each offering distinct advantages in terms of mechanical properties and application suitability. According to a report from the American Foundry Society, A380 is favored for its excellent fluidity and surface finish, making it ideal for intricate designs and components requiring a high degree of detail. In contrast, A356 is often chosen for applications demanding higher strength and corrosion resistance, which is particularly beneficial in automotive and aerospace industries.

Cost considerations also play a significant role in the choice of aluminum alloys. Alloy A380 tends to be less expensive due to its widespread availability and simplified processing, making it a popular choice for high-volume production. However, A356, while initially costlier, can lead to lower overall project costs in applications where durability and performance are paramount. A study by the Aluminum Association suggests that using high-strength alloys can result in a 20% reduction in maintenance costs over the life cycle of a component, emphasizing the long-term financial benefits of choosing the right alloy for specific applications. Understanding these factors will enable project managers and engineers to make informed decisions that align with both budget constraints and performance requirements.

| Aluminum Alloy | Cost per kg | Tensile Strength (MPa) | Corrosion Resistance | Typical Applications |

|---|---|---|---|---|

| A356.0 | $3.00 | 260 | Good | Automotive, Aerospace |

| A380.0 | $3.25 | 310 | Moderate | Electrical Housings, Engine Blocks |

| A535.0 | $2.75 | 210 | Excellent | Marine Applications, Outdoor Equipment |

| A319.0 | $3.50 | 240 | Good | Engine Components, Structural Parts |

When sourcing reputable suppliers for die casting aluminum components, it's crucial to select partners that demonstrate a strong track record in quality and reliability. According to a recent industry report by Research and Markets, the global die casting market is expected to grow at a CAGR of 6.3% from 2021 to 2026, driven by increasing demand for lightweight and durable components in various sectors, including automotive and aerospace. Therefore, finding a supplier who not only understands the technical requirements of aluminum die casting but also adheres to international quality standards can significantly enhance the success of your project.

In addition to quality assurance, evaluating a supplier’s production capabilities is essential. A study by Freedonia Group highlighted that manufacturers increasingly prefer suppliers who utilize advanced technologies such as computer-aided design (CAD) and automated quality control systems. These technologies ensure precision and minimize defects, aligning with the industry's shift towards high-quality, close-tolerance components. When assessing potential suppliers, inquire about their production processes, certifications (like ISO 9001), and any past projects that illustrate their expertise in handling specific requirements of aluminum die casting. This due diligence will help mitigate risks and foster long-term, mutually beneficial partnerships in your manufacturing endeavors.

This chart displays key metrics for evaluating die casting aluminum parts suitable for different projects. The weight is measured in grams, production time in hours, cost per unit in dollars, and the defect rate as a percentage.