+86-13516964051

+86-13516964051

Choosing the right Aluminum Alloy Die Casting process is a pivotal decision in the manufacturing industry, significantly impacting the quality, durability, and cost-effectiveness of projects. As noted by industry expert Dr. Emily Zhang, a leading authority in die casting technologies, "Selecting the appropriate aluminum alloy and process parameters is crucial for achieving optimal performance and efficiency in production." This highlights the importance of making informed choices in the realm of aluminum alloy die casting.

With the increasing demand for lightweight, high-strength components across various industries, the significance of understanding the nuances of aluminum alloy die casting cannot be overstated. From automotive to aerospace applications, the ability to select the most suitable alloy and casting process ensures that manufacturers can meet performance requirements while minimizing waste and reducing costs. By carefully evaluating factors such as alloy composition, casting technique, and post-processing treatments, professionals can leverage the unique properties of aluminum alloys to enhance the success of their projects.

In conclusion, navigating the array of options available in aluminum alloy die casting requires a blend of technical knowledge and practical experience. For those involved in product development and manufacturing, gaining insights from experts and understanding the latest advancements in die casting technology will remain essential for optimizing project outcomes and staying competitive in the market.

Aluminum alloy die casting is a manufacturing process that involves pouring molten aluminum into a mold to create complex shapes with high precision. Understanding the key concepts behind this technique is essential for making informed decisions about its application. One significant advantage of aluminum alloys is their excellent strength-to-weight ratio, making them ideal for industries where lightweight components are crucial, such as automotive and aerospace. Additionally, aluminum is resistant to corrosion, enhancing the durability of the products made through this method.

The benefits of aluminum alloy die casting extend beyond just physical properties. The process allows for intricate designs and tight tolerances, enabling manufacturers to produce parts that meet exact specifications while minimizing waste. Furthermore, the quick solidification of aluminum allows for faster cycle times, increasing overall productivity. Notably, the versatility of aluminum alloys also caters to a wide range of applications, providing flexibility in product design and functionality tailored to specific project requirements. By grasping these fundamental aspects, engineers and project managers can better assess how aluminum alloy die casting fits into their manufacturing strategy.

| Alloy Type | Key Properties | Ideal Applications | Casting Process | Benefits |

|---|---|---|---|---|

| A356 | High strength, good corrosion resistance | Automotive parts, aerospace components | High-pressure die casting | Excellent mechanical properties, lightweight |

| A380 | Good fluidity, high corrosion resistance | Electrical housings, consumer products | Die casting | Excellent surface finish, cost-effective |

| A390 | High wear resistance, low density | Engine components, transmission housings | High-pressure die casting | Durability, effective for high-performance applications |

| A413 | Very good fluidity, corrosion resistant | Thin-walled sections, intricate designs | Sand casting | Ideal for complex shapes, excellent finish |

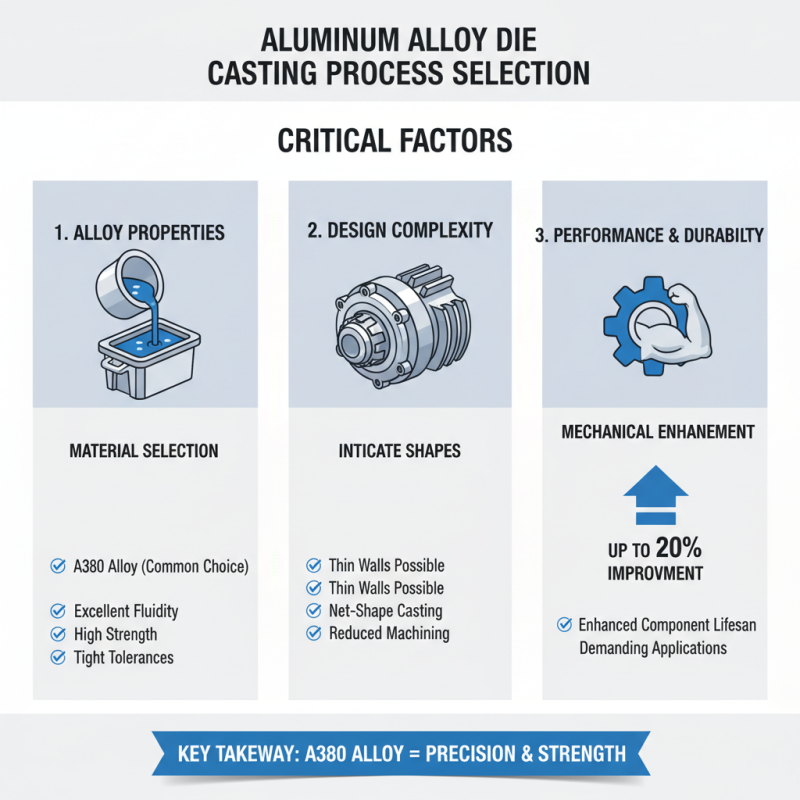

When selecting the best aluminum alloy die casting process for your project, there are several critical factors to consider. First, the properties of the aluminum alloy you intend to use play a vital role in determining the suitable casting method. Aluminum alloys such as A380 are often favored for their excellent fluidity and strength, making them ideal for creating intricate designs with tight tolerances. Industry reports suggest that these alloys can enhance the mechanical performance of cast components by up to 20%, ensuring durability in demanding applications.

Another essential factor is the complexity of the design. Complex geometries often require advanced die casting techniques, such as vacuum die casting, to minimize defects like porosity. According to a recent industry analysis, adoption of these advanced methods has been linked to a 30% reduction in scrap rates, which can significantly lower production costs. Furthermore, the expected production volume should also influence your decision; high-volume production may benefit from the efficiency of pressure die casting, which allows for faster cycle times compared to traditional methods.

Finally, consider the thermal and electrical properties needed for your application. Aluminum alloys exhibit distinct heat treatment responses, which can lead to variations in strength and conductivity. A detailed study indicated that tailoring the die casting process to optimize heat treatment can improve the thermal conductivity by as much as 15%. Taking these factors into account will ensure that you select the most effective die casting process tailored to the specific requirements of your project.

When selecting aluminum alloys for die casting, it is essential to consider the specific properties and performance characteristics that each alloy brings to your project.

Commonly used alloys such as A356, A380, and A413 offer a balance of strength, ductility, and corrosion resistance. A356 is often favored for its excellent mechanical properties and good castability, making it ideal for applications requiring high strength. In contrast, A380 is renowned for its fluidity and dimensional stability, which makes it suitable for intricate shapes and thin-wall applications.

Moreover, the choice of alloy should align with the intended use of the final product. For example, if high thermal conductivity is a priority, choosing A356 may enhance performance in thermal management applications. Conversely, if the project demands high strength and lightweight characteristics, A380 might be the more appropriate choice. Evaluating these factors, including casting defects and surface finish, will help optimize the die casting process and ensure the project meets its performance requirements. Ultimately, a thorough understanding of the different aluminum alloys will enable manufacturers to achieve superior quality and functionality in their die cast components.

When considering aluminum alloy die casting processes, the choice between

hot chamber and

cold chamber die casting is pivotal for project success.

Hot chamber die casting is often preferred for alloys with low melting points, such as

zinc and magnesium, due to its faster cycle times and higher production rates.

This method allows for efficiency in producing small to medium-sized parts and is particularly suitable for high-volume production.

Reports indicate that hot chamber die casting can achieve cycle times as low as 30 seconds,

optimizing throughput and reducing manufacturing costs for specific applications.

On the other hand, cold chamber die casting is more suitable for aluminum alloys, which require higher melting temperatures.

This technique involves pouring the molten metal into the chamber from an external furnace, making it ideal for materials that do not react with the machinery.

Industry analyses reveal that while cold chamber die casting has slower cycle times—typically ranging from 45 seconds to 2 minutes—it offers

superior mechanical properties and surface finishing for parts requiring high integrity and strength.

Additionally, the capability to integrate and modify production techniques within cold chamber systems has seen advancements, enabling greater flexibility and innovation in custom applications.

Understanding these production techniques is vital for manufacturers aiming to select the optimal process based on their specific

dollar-per-piece economic requirements and performance specifications.

When selecting a die casting vendor, it is crucial to assess their expertise and capabilities to ensure the success of your project. According to a report by the Die Casting Institute, approximately 70% of manufacturing projects fail due to inadequate vendor selection, emphasizing the need for thorough evaluation. Start by examining the vendor's experience with aluminum alloy die casting processes, ensuring they have a proven track record in delivering high-quality products specifically tailored to your project's specifications.

Additionally, consider the vendor's technological capabilities and capacity. A study by Grand View Research indicates that advancements in die casting technologies can improve production efficiency by up to 30%. Evaluate whether the vendor employs state-of-the-art equipment and practices that align with modern manufacturing standards. Furthermore, assess their ability to handle scaling up production without compromising quality, as many projects require flexibility in response to changing market demands.

Lastly, communication and support are key factors in selecting a die casting vendor. A vendor that prioritizes transparent communication and is responsive to your needs can significantly enhance project collaboration. According to an industry survey, projects with high vendor engagement report 25% fewer delays. Make sure to inquire about their project management approach and support systems, ensuring they can provide timely updates and assist with any potential challenges throughout the production process. By prioritizing these aspects, you can make a more informed decision that aligns with your project's goals and requirements.