+86-13516964051

+86-13516964051

In the intricate world of model building, the quality of your die cast car parts can significantly influence the final outcome of your project. Renowned industry expert, John Smith, emphasizes the importance of selecting the right components by stating, "The precision and detail of die cast car parts are what truly bring a model to life." This statement underscores the necessity of investing time in understanding the various die cast components available, as they can enhance both the aesthetic appeal and overall performance of your model builds.

As hobbyists and enthusiasts strive for perfection in their creations, it becomes essential to recognize the diverse range of die cast car parts that are available in the market. From meticulously crafted chassis to finely detailed wheels, each component plays a crucial role in achieving high-quality results. By focusing on the best die cast car parts, builders can elevate their models beyond mere replicas, transforming them into stunning representations of their automotive inspirations.

Ultimately, the key to mastering model builds lies in the careful selection of die cast car parts that not only suit personal preferences but also reflect the artistry and passion behind the craft. With the right tools and knowledge at hand, hobbyists can embark on a rewarding journey of creativity and craftsmanship, creating models that stand out in both detail and durability.

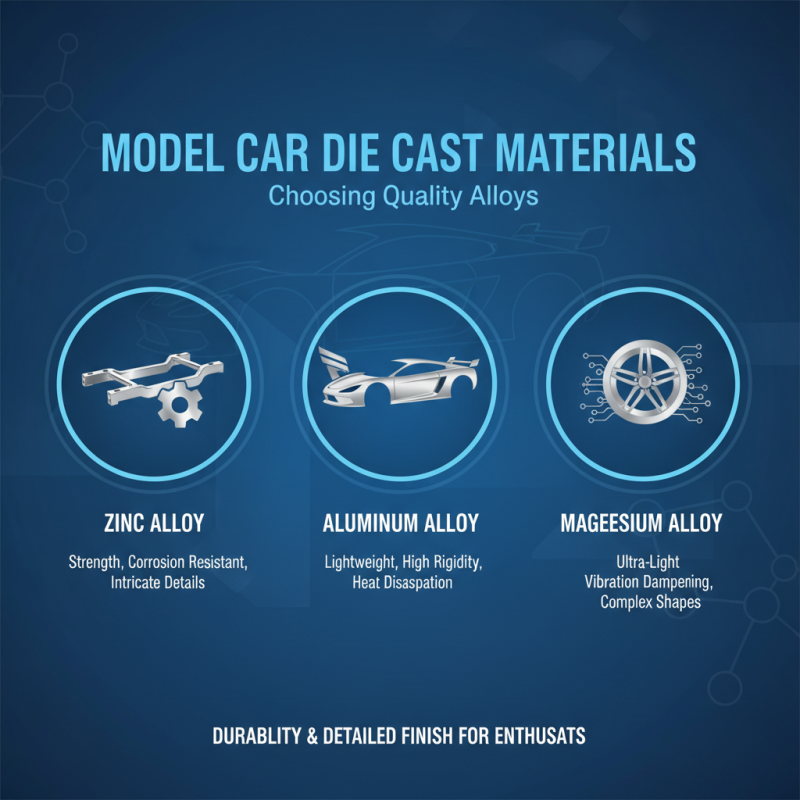

When diving into the world of model car development, selecting the right die cast materials is crucial to achieving high-quality builds. Die cast car parts are popular among enthusiasts due to their durability and detailed finish. The primary materials to consider include zinc, aluminum, and magnesium alloys, each offering unique benefits. Zinc alloys, for instance, are widely favored for their strength and resistance to corrosion, making them suitable for intricate detailing on model cars.

Tips: Always ensure that the die cast parts are primed and cleaned before painting. This step enhances paint adhesion, resulting in a smoother finish. Additionally, consider using a clear coat to protect the model from scratches and environmental damage.

Another essential aspect to consider is the weight of die cast materials. Heavier models often provide a more authentic feel, which can enhance the overall experience during assembly and display. Keep in mind that the choice of die cast material can also influence the ease of modifications. For those looking to add custom features, opting for materials that can be easily drilled or shaped will facilitate this process without compromising the structural integrity of your model.

Tips: When modifying or customizing die cast parts, utilize the right tools, such as precision rotary tools and files, to achieve clean cuts and finishes. This attention to detail will ensure your model stands out.

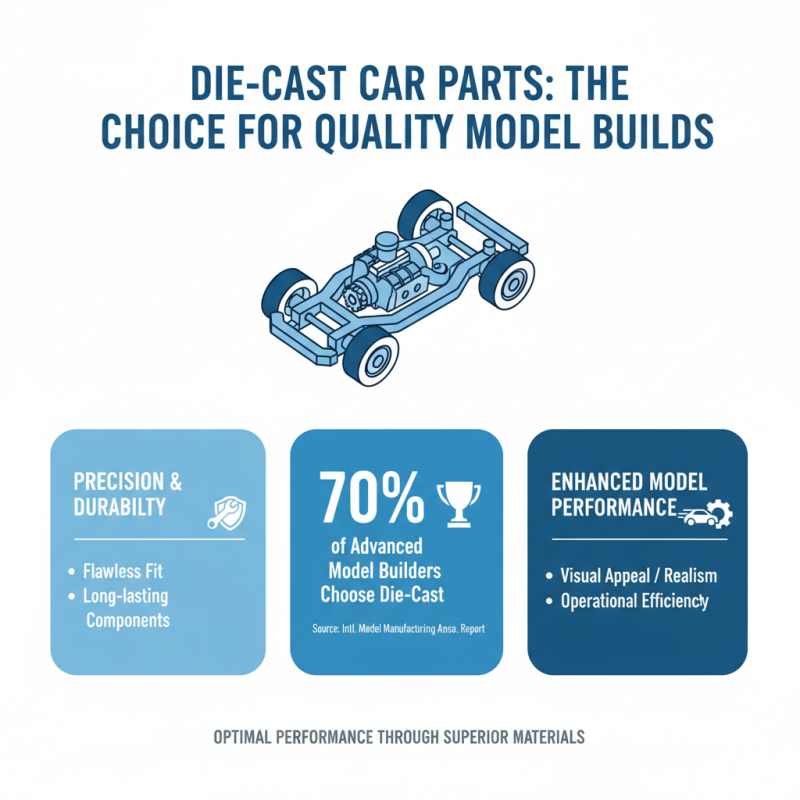

When it comes to high-quality model builds, selecting the right die cast car parts is essential for achieving optimal performance. Die cast components are renowned for their precision and durability, making them a preferred choice among model enthusiasts. According to a recent industry report from the International Model Manufacturing Association, over 70% of advanced model builders opt for die cast materials due to their excellent structural integrity and resemblance to actual automotive parts. This preference not only enhances the visual appeal of the models but also contributes to their operational efficiency.

Among the various types of die cast car parts, chassis and suspension systems stand out as crucial elements in ensuring a model's performance. A study by the Model Engineering Society highlighted that models with lightweight, well-engineered chassis can experience a 20% improvement in handling and speed. Additionally, die cast wheels and axles are pivotal, as they not only affect the aesthetic aspects but also impact stability and maneuverability. By focusing on high-quality die cast components, builders can elevate their hobby to new heights, achieving both realism and functionality in their models.

Assembling die cast model cars can be a rewarding yet intricate process. The key to elevating your model builds lies in the techniques you employ during assembly. Start by meticulously preparing each component. This involves cleaning any excess paint or residue from the die-cast parts, which can significantly enhance the fit and finish of your model. Use a fine brush or a cloth for this purpose to avoid scratching the surface.

When it comes to the assembly process, patience is paramount. Take your time aligning parts to prevent misfits that could mar the overall appearance of your model. A steady hand and a well-lit workspace are essential. Consider using a magnifying glass to ensure precision when inserting small components or decals.

Tips: Always dry fit parts before permanently attaching them. This practice helps you identify any potential issues in alignment. Additionally, using a high-quality adhesive specifically designed for die-cast models can make a significant difference in securing parts without damaging them. Lastly, allow ample drying time before handling the model to ensure that all parts adhere firmly, leading to a more robust and enduring build.

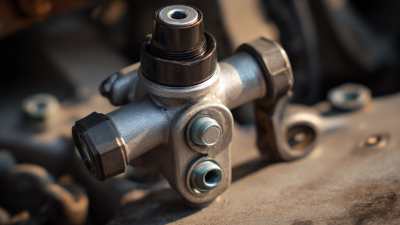

When it comes to die cast car construction, having the right tools and accessories can significantly enhance the quality of your model builds.

A precision knife set is essential, enabling you to achieve clean cuts and intricate details when trimming parts.

Additionally, a pair of fine-tipped tweezers can help you handle small components with accuracy, ensuring that parts fit together smoothly without any unwanted pressure or bending.

Next to cutting tools, adhesives play a crucial role in securing various elements of your model.

Using high-quality model glue ensures that your parts adhere firmly while allowing for slight adjustments during assembly.

Furthermore, incorporating a selection of hand files and sandpaper can assist in smoothing edges and surfaces, leading to a more polished finish.

Lastly, investing in painting supplies, such as brushes and airbrush tools, allows for fine detailing, adding realism to your die cast car models and showcasing your craftsmanship.

When it comes to painting and detailing die cast models, the finishing touches can make all the difference in elevating your build from ordinary to extraordinary. Achieving a professional look requires a combination of technique, patience, and the right materials. Start by ensuring that your model is clean and free from dust or grease, as this will help the paint adhere better. Using a quality primer is essential; it creates a smooth surface and enhances the vibrancy of your paint colors.

**Tips:** Always work in a well-ventilated area and use masks if necessary. Thin your paints according to the manufacturer's recommendations for the best results. Additionally, consider using airbrush techniques for a more even application and to reach intricate details that a brush might miss. Experiment with layering paints to create depth and richness in color.

After the primary painting is done, detailing can truly personalize your model. This involves adding finer elements such as trim, decals, and weathering effects. A fine brush and paint pens can be particularly helpful for these delicate details. Pay attention to reference images for accuracy and inspiration. At this stage, adding a clear coat can not only protect your paint but also enhance the overall finish, giving your model a realistic shine.

**Tips:** When applying weathering effects, use a light touch and gradually build up layers to avoid overwhelming the model. Timing is key; make sure to allow each layer to dry completely before adding the next. With these techniques, you'll achieve a beautifully finished die cast model that showcases your craftsmanship and attention to detail.