+86-13516964051

+86-13516964051

In the fast-evolving industry of manufacturing, the "Aluminum Die Casting Mould" plays a crucial role. Experts like James Thompson, a leading figure in die casting technology, emphasize that "The quality of the mould directly impacts production efficiency." This highlights the necessity for high-quality designs and materials.

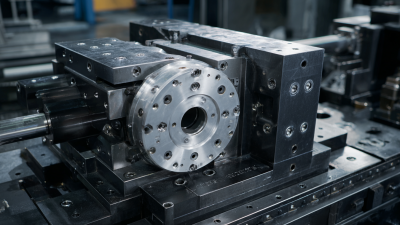

Aluminum die casting is not just about creating moulds. It's about precision and reliability. Companies must consider factors such as temperature control and mold design intricacies. A poorly designed mould can lead to defects, wasted materials, and increased costs. Addressing these issues requires an understanding of both technology and the specific application needs.

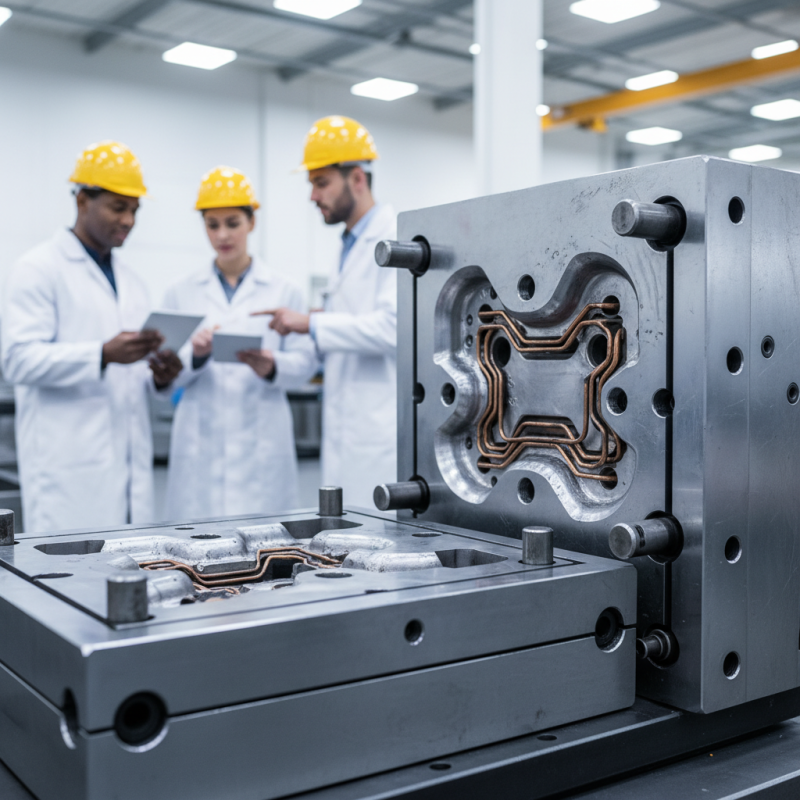

Quality production hinges on collaboration among designers, engineers, and manufacturers. It’s a journey of constant improvement. The challenge remains: how to find the best practices and materials. Continuous evaluation is needed to adapt to market demands. Only then can the full potential of the Aluminum Die Casting Mould be realized.

In the world of manufacturing, aluminum die casting moulds play a crucial role in ensuring quality production. These moulds are essential for creating precise parts. They allow for efficient mass production while maintaining the integrity of designs. However, not all moulds achieve the same level of quality, making careful selection important.

When choosing a die casting mould, consider the material quality. Poor quality materials can lead to defects. Make sure the mould can withstand high temperatures and pressure. This is vital for consistency in production. Inadequate moulds may cause a high rejection rate of parts due to imperfections.

Tips: Regular maintenance is key. Inspect moulds for wear and tear frequently. This will prolong their lifespan and ensure quality output. Also, don't overlook the design phase. A complex design can complicate the mould-making process. Keep it simple yet effective.

In this industry, it’s common to face challenges. Sometimes, unexpected issues arise during production. Reflect on these moments. They can provide valuable insights for future projects. Continuous improvement is the goal, making each setback a learning opportunity.

| Mould Type | Material Used | Production Rate (Units/hour) | Dimensional Tolerance (mm) | Typical Applications |

|---|---|---|---|---|

| High Pressure Die Casting | Aluminum Alloy ADC12 | 300 | ±0.05 | Automotive Parts |

| Low Pressure Die Casting | Aluminum Alloy A380 | 150 | ±0.1 | Consumer Electronics |

| Gravity Die Casting | Aluminum Alloy A356 | 100 | ±0.15 | Industrial Equipment |

| Sand Casting | Aluminum Alloy A413 | 50 | ±0.2 | Machinery Components |

| Die Casting with Inserts | Aluminum Alloy 6061 | 120 | ±0.05 | Aerospace Parts |

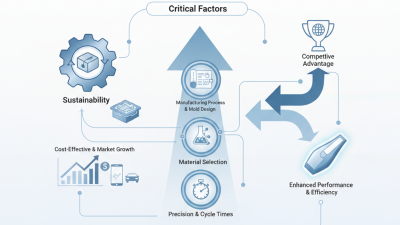

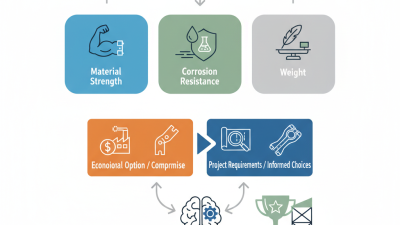

Choosing the right die casting mould is crucial for producing high-quality aluminum parts. Several key factors come into play. Material selection is vital. The mould's material must withstand high temperatures and pressures. Steel and aluminum are popular choices, but they come with pros and cons. Steel offers durability but may be more expensive.

Design complexity is another consideration. Sometimes, intricate designs require more advanced moulds. This can increase costs and lead times. It’s essential to balance complexity with production efficiency. An overly complicated mould may not yield optimal results.

Lastly, the intended production volume should guide mould selection. High-volume production can justify a more durable mould. But for smaller batches, a simpler mould might suffice. An inappropriate choice can lead to defects and waste, impacting overall quality. It's a delicate balance that demands reflection and assessment.

The aluminum die casting industry is evolving rapidly. In 2026, new technologies promise to enhance quality and efficiency. Innovations focus on automation and improved alloys. These advancements streamline production processes. They also help reduce waste, which is a key concern in manufacturing.

Tips: Regular training for operators is essential. Familiarize them with new technologies for better efficiency. A skilled workforce can prevent errors that lead to costly defects.

Another trend in 2026 is 3D printing’s integration. This allows for rapid prototyping of molds. Companies can create complex designs with reduced lead times. However, the learning curve can be steep. Embracing this technology requires time and investment.

Tips: Start with small projects to gauge the benefits. This approach minimizes risk and allows for adjustments. Reflect on outcomes to optimize processes and decisions moving forward.

When considering the best aluminum die casting mold for quality production, it's essential to analyze leading manufacturers in the industry. Different manufacturers have distinct design philosophies and production techniques. Some prioritize material strength, while others focus on precision engineering or cost-effectiveness. These differences impact the overall quality of the molds they produce.

One notable aspect is the variability in their customer support. A company with solid support can enhance the user experience. Quick responses and helpful guidance can ease the production process. Conversely, a lack of communication can lead to frustration and operational delays. Additionally, how manufacturers handle post-sale services often reveals their commitment to quality. Some offer maintenance packages, while others leave their customers in the lurch.

Another critical factor is the innovation within the mold-making process. Not all companies embrace new technologies. Some are stuck in traditional methods, which may not meet current demands. Others explore advanced techniques to improve efficiency and reduce waste. This is where molds become a blend of old and new. Reflections on these aspects can help companies select the right partner for their production needs. Each choice presents unique challenges and benefits that need careful consideration.

In aluminum die casting, maintaining high quality in production is crucial. Industry reports indicate that 30% of casting defects arise from poor maintenance and operator errors. Regular upkeep of molds is essential. For instance, a mold that isn't cleaned properly can lead to surface imperfections. These defects reduce the overall strength and aesthetic quality of the final product.

Adopting best practices can mitigate these issues. Implementing a routine inspection schedule can help identify wear and tear. Reports show that consistent climate control during the pouring process can reduce thermal fatigue in molds. Proper cooling prevents deformation, which is vital for intricate designs. In contrast, neglecting these practices can lead to significant waste and increased costs.

Training operators is equally important. Well-trained personnel are less likely to make errors during the die casting process. In fact, studies reveal that companies with comprehensive training programs see up to 50% fewer defects. Overall, maintaining quality in aluminum die casting requires attention to detail and a commitment to continuous improvement.