+86-13516964051

+86-13516964051

Choosing the right Aluminum Casting Machine is crucial for any manufacturing operation. This decision can significantly impact efficiency and product quality. With various options on the market, it is essential to evaluate features carefully.

Different machines serve different purposes. Some are better for small-scale production, while others excel in high-volume settings. Consider your production needs and limitations. It is often challenging to find a machine that meets all criteria perfectly. Many machines come with trade-offs.

Investing in the right Aluminum Casting Machine may bring significant benefits. However, it's important to reflect on past experiences. Not every machine performs as expected. Researching customer reviews can aid in making an informed choice. Ultimately, a well-chosen machine can enhance your manufacturing process and lead to better results.

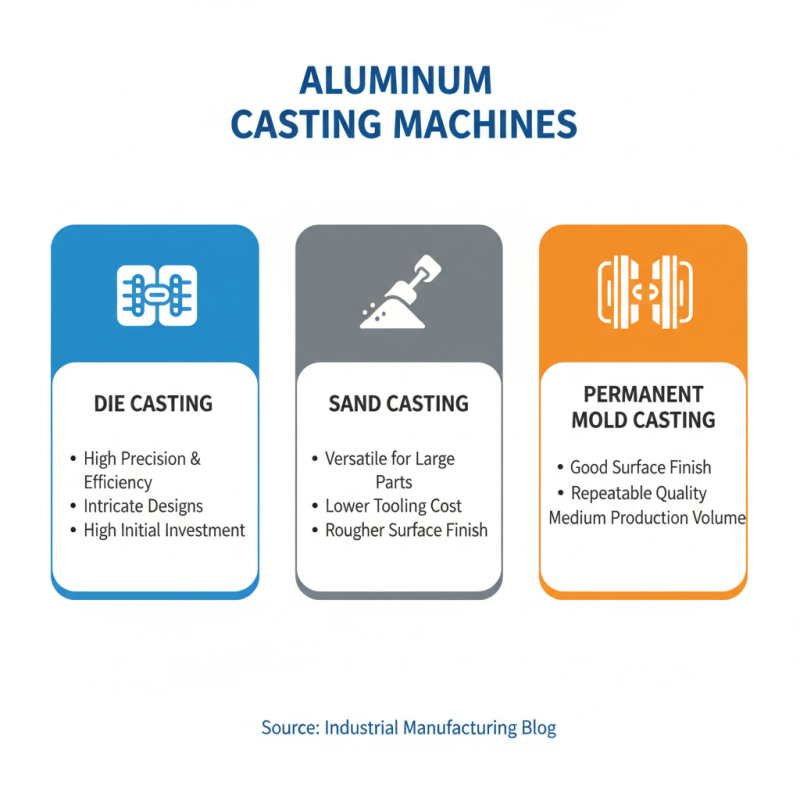

When exploring aluminum casting machines, you'll find several types catering to different manufacturing needs. The primary categories include die casting, sand casting, and permanent mold casting machines. Each type has unique advantages and challenges. For instance, die casting machines offer high precision and efficiency. They can produce intricate designs quickly. However, they require significant initial investment.

Sand casting machines are quite versatile. They allow for larger pieces and complex molds. The setup is simpler, making it accessible for small operations. Yet, the finish might not always be perfect. This process sometimes leads to surface imperfections that require additional finishing.

Permanent mold casting is another option. It balances speed and quality of finishes. These machines can deliver reliable outcomes. However, they may not be suitable for high-volume production settings. Choosing the right machine is crucial. Each option has implications on cost, quality, and production speed. Manufacturers must carefully assess their specific needs and limitations.

When selecting an aluminum casting machine, consider key features that impact your production efficiency. One crucial aspect is the machine's capacity. It's essential to choose a model that meets your volume needs. If your requirements fluctuate, opt for a versatile machine that can adapt. Next, keep an eye on the power consumption. Machines that save energy can reduce operational costs in the long run.

Another important feature is the cooling system. Effective cooling can enhance casting quality and prevent defects. Pay attention to usability as well. A user-friendly interface can ease the learning curve for your team. Sometimes, the most advanced technology can be challenging to operate. Additionally, evaluate maintenance requirements. A machine that is difficult to service can lead to extended downtime.

Lastly, consider the machine’s compatibility with various aluminum alloys. The right machine should accommodate different materials, enhancing flexibility. Reflect on these aspects carefully. Not every machine will meet all your needs perfectly, and you must weigh the pros and cons. Finding the ideal aluminum casting machine might take time, and some choices may not live up to expectations.

When selecting an aluminum casting machine, various brands and models stand out in the market. Industry reports indicate that the demand for high-performance casting equipment has surged by over 25% in recent years. This trend highlights the importance of choosing reliable and efficient machinery tailored to specific manufacturing needs.

Several models are particularly noteworthy. Some machines are known for their rapid cycle times, enhancing productivity. Others emphasize precision, vital for intricate designs. However, a common issue arises with maintenance. Frequent downtime for repairs can disrupt production schedules. Data shows that manufacturers often overlook this aspect, focusing solely on output efficiency.

Moreover, energy consumption in aluminum casting can be significant. Reports confirm that newer models are designed to be more energy-efficient. Yet, many factories still operate older machines, which can lead to higher operational costs. Balancing cost and performance is crucial. Therefore, manufacturers should carefully assess their long-term needs before investing in new equipment.

| Model | Max Capacity (tons) | Features | Price Range ($) | User Rating (out of 5) |

|---|---|---|---|---|

| Model A | 5 | Automatic, High efficiency | 15,000 - 20,000 | 4.8 |

| Model B | 10 | User-friendly, Compact design | 20,000 - 30,000 | 4.5 |

| Model C | 15 | Advanced casting technology, Low energy consumption | 30,000 - 40,000 | 4.7 |

| Model D | 8 | Robust construction, High durability | 18,000 - 25,000 | 4.6 |

| Model E | 12 | Fast production speed, Reliable performance | 22,000 - 28,000 | 4.4 |

Investing in an aluminum casting machine requires careful budgeting. The costs generally range from $50,000 to $200,000, depending on the machine's capabilities. A key factor in your decision is the intended production volume. Machines with higher outputs tend to cost more. Yet, they can lead to significant savings over time. Understanding your production needs helps avoid overspending.

Another consideration is ongoing operational costs. These machines consume energy, affecting overall budget. According to industry reports, energy costs for aluminum casting can represent 25% of total operational expenses. Maintenance is also essential. Regular upkeep can prevent costly downtimes. Some manufacturers might overlook this point, leading to unexpected expenses.

Don’t forget about the potential for additional costs. Software for design and control systems can add thousands to the initial investment. Training staff to operate sophisticated machines might incur extra costs too. Balancing these factors is crucial. While the upfront cost is significant, long-term savings can provide a solid return on investment if managed wisely.

Maintenance plays a crucial role in extending the lifespan of aluminum casting machines. Experts recommend regular inspections to prevent unexpected breakdowns. Data shows that proper maintenance can increase machine longevity by up to 30%. A simple routine can save thousands in repairs.

Lubrication is essential. Use the right oil to minimize wear and tear on moving parts. Neglecting lubrication can lead to overheating and reduced efficiency. It's surprising how many operators overlook this simple task. Dust and debris can accumulate, obstructing key components. Keeping the workspace clean can enhance machine performance significantly.

Operators should also monitor operating temperatures. Machines running too hot may indicate underlying issues. These problems often go unnoticed until it’s too late. Regular temperature checks can help identify them early. Training personnel on maintenance protocols is vital. Knowledgeable staff can make a big difference. Ignoring these tips can result in costly downtimes and less productivity.