+86-13516964051

+86-13516964051

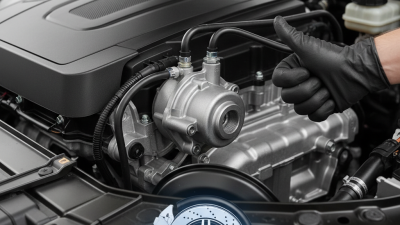

Aluminum parts have revolutionized the manufacturing industry. With their lightweight nature and corrosion resistance, they offer significant advantages. Dr. Emily Chen, a leading expert in materials engineering, states, "The versatility of aluminum parts drives innovation in various sectors." Manufacturers can achieve better efficiency using aluminum parts. Their reduced weight can lead to increased fuel efficiency in transportation. However, challenges remain in recycling and production costs. Companies must devise strategies to address these issues. Adopting aluminum parts is not merely about benefits. The industry must also confront realities in sustainability and market demands. As businesses integrate aluminum, they need to ensure responsible sourcing and production practices. Aluminum parts can be a game-changer, but careful consideration is essential.

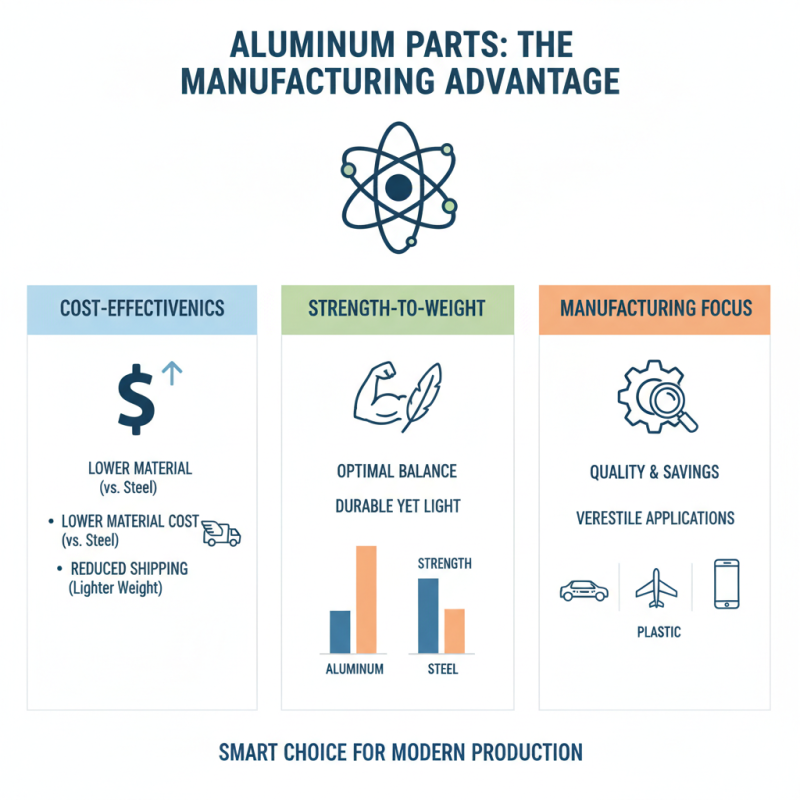

Aluminum parts offer numerous benefits in manufacturing. They are lightweight yet strong, making them ideal for various applications. According to a report from the Aluminum Association, aluminum can be 30% to 50% lighter than steel. This weight reduction leads to lower transportation costs and improved fuel efficiency in vehicles.

In aerospace, using aluminum reduces overall aircraft weight, a critical factor for efficiency.

Aluminum also boasts excellent corrosion resistance. This attribute increases the lifespan of parts significantly. Industries like automotive and construction benefit the most from this characteristic. A study from the International Aluminum Institute shows that aluminum's natural resistance to corrosion can extend product life by up to 50%. Manufacturers spend less on replacements and repairs, enhancing overall productivity.

However, there are challenges. Aluminum can be more expensive than other materials initially. Some manufacturers hesitate to switch due to higher upfront costs. Additionally, joining aluminum parts requires specific techniques, which may not be readily available in all facilities. These factors require careful consideration when integrating aluminum into production lines. The potential benefits often outweigh these initial drawbacks, but it’s crucial to evaluate specific project needs and capabilities.

Aluminum has emerged as a popular choice in manufacturing, mainly due to its lightweight properties. This metal weighs about one-third as much as steel. Such a reduction in weight can greatly enhance production efficiency. With lighter parts, machines use less energy to operate. This can lead to savings on electricity bills and reduce wear and tear on machinery.

In diverse industries, lighter components optimize handling. Workers can lift and move parts easily. This ease of use can cut down on labor costs and minimize injury risks. However, the downsides should be acknowledged. Lighter materials sometimes impact the overall strength of parts. Engineers must consider trade-offs carefully. Not every application benefits from weight reduction—some require stronger materials.

These advantages draw many manufacturers towards aluminum. Yet, it’s essential to contemplate the specific needs of each project. The balance between weight and strength can be a tricky one. Simply choosing aluminum for its lightness without thorough testing may lead to unforeseen challenges. Manufacturers must remain vigilant and critical, ensuring the best outcomes in their production lines.

Corrosion resistance is a crucial benefit of using aluminum parts in manufacturing. Aluminum naturally forms a protective oxide layer. This layer shields the material from moisture and various chemicals, significantly slowing down corrosion. Studies show that aluminum components can last up to 50 years without significant deterioration in harsh environments. In sectors like transportation, this longevity means fewer replacements and lower operational costs.

Maintenance costs also see a pronounced reduction. Equipment that resists corrosion needs less frequent inspections and repairs. According to a report by the International Aluminum Institute, companies using aluminum parts cut maintenance costs by an estimated 30%. That's substantial, especially in industries where downtime can lead to severe losses. However, this focus on corrosion resistance does not eliminate the need for proper maintenance practices. Users must balance this benefit with regular checks to ensure optimal performance.

Despite the advantages, aluminum is not flawless. Its susceptibility to galvanic corrosion when in contact with certain metals is a concern. Proper design choices must mitigate this risk. By treating aluminum components carefully during assembly, its benefits can truly shine. Investing in aluminum might seem costly upfront, but the long-term savings can be significant with proper management.

| Benefit | Description | Impact on Longevity | Impact on Maintenance Costs |

|---|---|---|---|

| Corrosion Resistance | Aluminum forms a protective oxide layer that prevents further corrosion. | Significantly increases the lifespan of components in harsh environments. | Reduces frequency of repairs and replacements, lowering costs. |

| Lightweight | Aluminum is significantly lighter than many metals, reducing overall weight. | Allows for easier handling and longer-lasting support structures. | Lowers transportation and installation costs. |

| Thermal Conductivity | Aluminum has excellent thermal conductivity characteristics. | Enhances efficiency in heat dissipation, prolonging component life. | Minimizes cooling system repairs and maintenance costs. |

| Recyclability | Aluminum can be recycled without loss of properties. | Contributes to sustainable practices and longevity of resources. | Reduces disposal and raw material costs over time. |

| Aesthetic Appeal | Aluminum offers an attractive finish and can be anodized for color. | Increases product desirability, improving market longevity. | May reduce costs associated with surface treatments and finishes. |

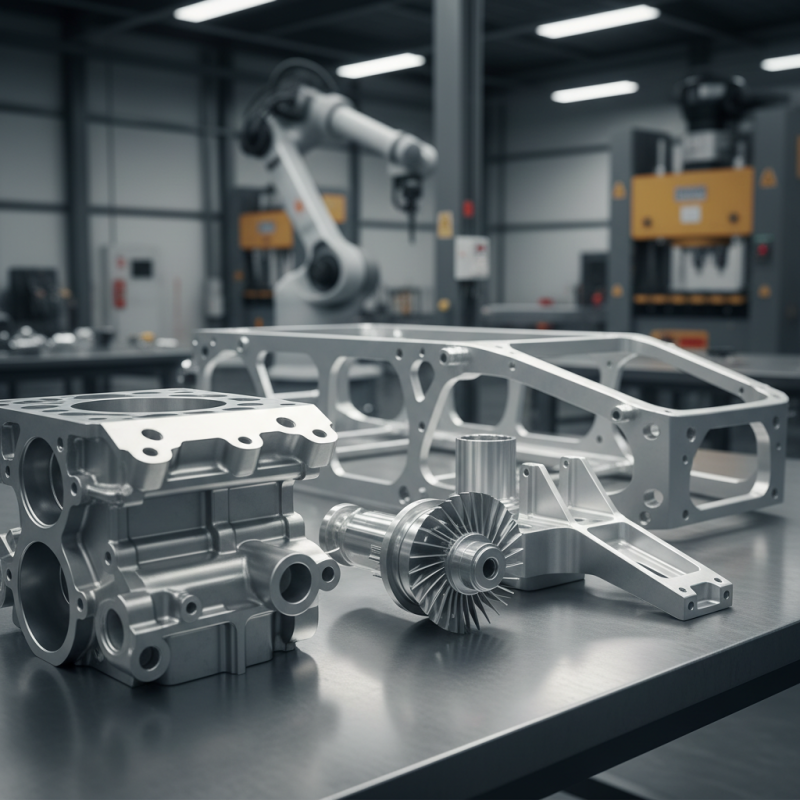

Aluminum parts have become a popular choice in manufacturing. Their cost-effectiveness is a significant factor. Compared to steel or plastic, aluminum offers a balance of strength and weight. This balance can lead to lower shipping costs. Many manufacturers focus on savings while maintaining quality.

The versatility of aluminum also helps reduce costs. It can be easily molded into various shapes. This adaptability minimizes waste during production. However, the initial costs of aluminum can be higher. Smaller companies might hesitate to invest at first. Yet, long-term savings often outweigh this concern.

Another consideration is the maintenance of aluminum parts. They resist corrosion better than some alternatives. This durability reduces replacement rates and overall costs. Yet, some manufacturers may overlook these benefits, focusing solely on upfront prices. Embracing aluminum requires thoughtful assessment and planning in manufacturing processes.

Aluminum is a key material in modern manufacturing. Its sustainability advantages are striking. Recycling aluminum saves up to 95% of the energy needed to produce new aluminum from raw materials, according to a report by the Aluminum Association. This substantial energy savings significantly reduces greenhouse gas emissions. In fact, recycling aluminum cuts emissions by 1.3 billion tons annually, equivalent to taking 17 million cars off the road. The environmental impact of aluminum production is a topic of concern. While primary aluminum production can be energy-intensive, the lifecycle benefits of aluminum recycling are noteworthy. A study published in the Journal of Cleaner Production revealed that recycling aluminum leads to a significant reduction in land use and pollution. However, challenges remain. Not all aluminum products are recycled effectively. Lack of awareness and inadequate recycling facilities hinder progress. Despite these issues, the use of aluminum supports a circular economy. Its properties make it highly versatile and long-lasting. With an infinite recyclability, aluminum can often be reused without compromising its quality. This potential offers a promising path toward a more sustainable future in manufacturing. While the industry has made strides, continuous improvements are necessary for optimal recycling practices.