+86-13516964051

+86-13516964051

In the realm of modern manufacturing, the pursuit of efficiency, cost-effectiveness, and product quality is paramount. One solution that has gained considerable traction is the use of Aluminum Die Casting Parts. These components offer a unique combination of lightweight durability and precision, making them an ideal choice for a diverse range of industries, from automotive to consumer electronics. The innovative die casting process not only enhances production speeds but also significantly reduces waste, aligning perfectly with the growing emphasis on sustainable manufacturing practices.

Aluminum Die Casting Parts stand out due to their exceptional mechanical properties and versatility. The manufacturing process allows for intricate designs that would be challenging or impossible to achieve with traditional machining methods. This adaptability to design requirements, coupled with the inherent advantages of aluminum—such as corrosion resistance and thermal conductivity—makes these parts invaluable for engineers and manufacturers alike. As industries continue to evolve, understanding the top benefits of Aluminum Die Casting Parts is crucial for businesses aiming to stay ahead in competitive markets while optimizing their manufacturing capabilities.

Aluminum die casting has gained considerable traction in various manufacturing sectors due to its numerous advantages. According to a report by MarketsandMarkets, the global die casting market is projected to reach $75.5 billion by 2025, driven significantly by the automotive and aerospace industries. The lightweight nature of aluminum allows for the production of strong and durable components, which are crucial for enhancing performance and efficiency in these sectors. Additionally, the ability to achieve intricate designs with tight tolerances provides manufacturers with flexibility in product development, enabling them to meet specific engineering requirements more effectively.

Another key benefit of aluminum die casting is its cost-effectiveness in high-volume production runs. A study conducted by Research and Markets indicates that die casting can reduce production costs by up to 30% compared to other manufacturing methods due to its low material waste and fast production speed. Moreover, aluminum’s excellent thermal conductivity and corrosion resistance make it an ideal choice for components that must withstand harsh environments. This combination of attributes not only prolongs the lifecycle of the parts but also minimizes maintenance costs, reinforcing the economic viability of aluminum die casting as a standard manufacturing process in various industries.

This chart illustrates the key benefits of using aluminum die casting parts in manufacturing. Each benefit is represented as a percentage, showcasing their relative importance in the industry.

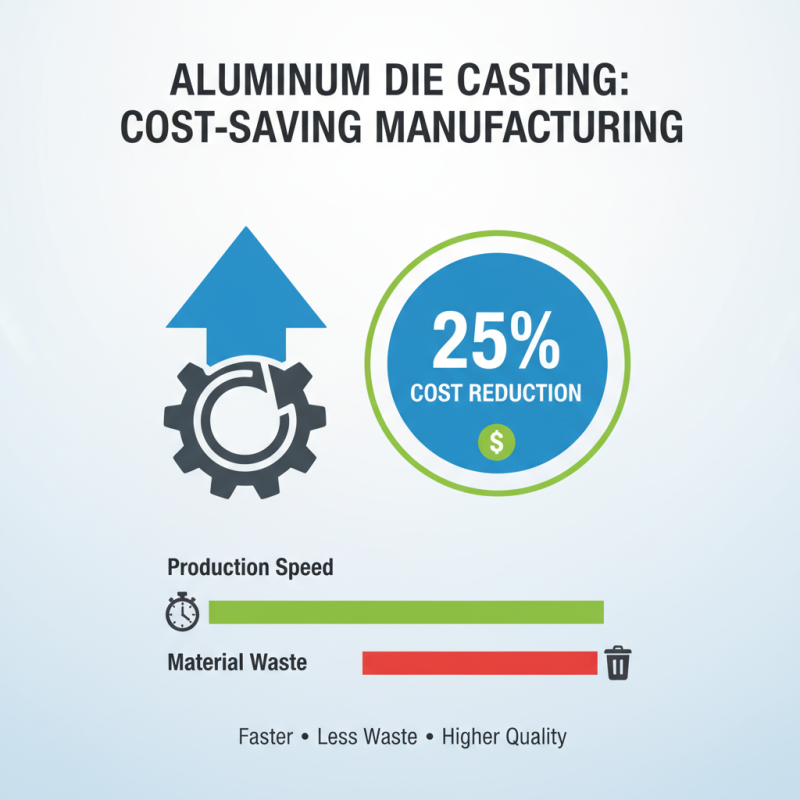

Aluminum die casting has emerged as a favored manufacturing process, particularly in sectors seeking to reduce costs while maintaining quality. According to a recent industry report by the Casting Industry Association, companies utilizing aluminum die casting processes can reduce production costs by up to 25% compared to traditional machining techniques. This significant cost reduction can be attributed to the advantages of faster production speeds and minimized material waste, making it an attractive option for manufacturers looking to optimize their budgets.

To further illustrate these benefits, case studies reveal that manufacturers transitioned to aluminum die casting and experienced a reduction in labor costs by up to 30%, due to lower machining requirements. Additionally, the recycling value of aluminum encourages manufacturers to adopt die casting, as nearly 80% of aluminum used in die casting can be reclaimed, translating into further financial benefits.

Tips: When considering aluminum die casting for your projects, ensure that you select the right tooling and machine settings to maximize efficiency. Regular maintenance of die casting equipment can also lead to significant cost savings by reducing downtime and enhancing production capabilities. Moreover, collaborating with experienced partners in the die casting field can provide valuable insights and help optimize your operations for better cost management.

Aluminum die casting has become increasingly popular in various manufacturing sectors due to its superior material properties, specifically its strength-to-weight ratio. According to the Aluminum Association, aluminum components can be up to 33% stronger than their steel counterparts while weighing significantly less. This lightweight advantage allows for easier handling and assembly, making it a favorite among industries such as automotive and aerospace, where every ounce counts towards improving fuel efficiency and performance.

In addition to its impressive strength, aluminum die cast parts exhibit excellent corrosion resistance, a feature driven by the natural oxide layer that forms on the material surface. A study by the U.S. Department of Energy highlights that using aluminum in vehicle manufacturing can enhance longevity and reduce maintenance costs, as these components can withstand harsh environmental conditions without succumbing to rust or deterioration. This durability combined with low density offers manufacturers an ideal solution when seeking materials that can support innovative designs while maintaining robustness. Ultimately, the combination of strength and lightweight properties in aluminum die casting plays a crucial role in driving efficiency and sustainability in contemporary manufacturing processes.

Die casting stands out as a pivotal process in manufacturing, particularly when it comes to achieving high precision and accuracy in parts production. Utilizing molten aluminum, die casting allows for the creation of intricately designed components that meet exacting specifications. The process involves forcing the aluminum into a mold under high pressure, which not only ensures that each part has a consistent shape but also minimizes material waste. This method is exceptionally beneficial for industries where dimensional tolerance is critical, as it produces parts that are both lightweight and robust.

The precision inherent in die casting significantly enhances manufacturing efficiency. Because the molds can be reused multiple times, they allow for high-volume production capabilities without sacrificing quality. This repeatability ensures that every component manufactured is nearly identical, reducing the need for extensive post-processing and inspection. Furthermore, the surface finishes achieved through die casting can often eliminate the need for additional machining, streamlining the overall production process and reducing lead times. As a result, manufacturers can meet the demands of complex projects more effectively, while also optimizing resource utilization and costs.

| Benefit | Description | Application |

|---|---|---|

| High Precision | Die casting allows for tight tolerances and intricate designs. | Automotive parts, consumer electronics |

| Cost-Effectiveness | High-volume production reduces cost per unit significantly. | Mass production scenarios |

| Lightweight | Aluminum parts are lighter compared to other metals. | Aerospace and automotive industries |

| Durability | Aluminum die-cast parts exhibit excellent corrosion resistance. | Outdoor equipment, marine applications |

| Complex Shapes | Can produce complex geometries without additional machining. | Custom machinery parts |

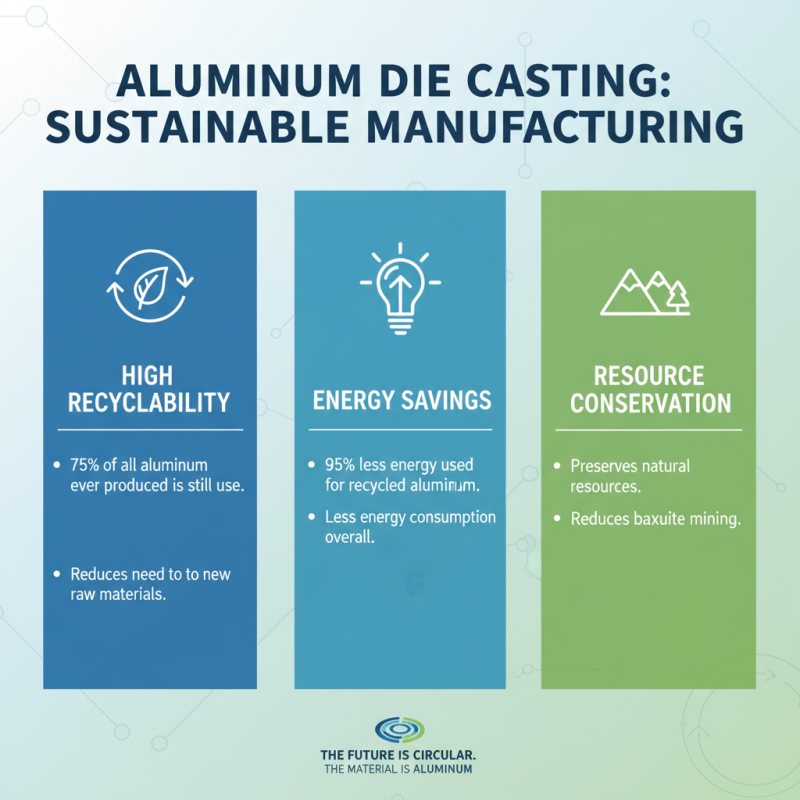

Aluminum die casting has emerged as a leading choice in sustainable manufacturing, largely due to its inherent environmental benefits. One of the most significant advantages of aluminum is its recyclability; nearly 75% of the aluminum ever produced is still in use today, according to the Aluminum Association. This high recyclability ratio not only reduces the need for raw material extraction but also minimizes energy consumption. In fact, recycling aluminum uses about 95% less energy compared to primary aluminum production. The U.S. Geological Survey has reported that aluminum recycling helps conserve significant amounts of natural resources, notably bauxite, the primary ore from which aluminum is derived.

Furthermore, aluminum die casting contributes to sustainable manufacturing practices by enabling lightweight design solutions that improve energy efficiency in applications such as automotive and aerospace. According to a study by the U.S. Department of Energy, lightweight materials can lead to fuel savings of 5% to 8% for every 10% reduction in vehicle weight. This translates into lower greenhouse gas emissions over the lifespan of vehicles. Additionally, the closed-loop recycling process in die casting facilities reduces waste generation and encourages responsible production, aligning with global sustainability goals. By embracing aluminum die casting, manufacturers can significantly lessen their environmental impact while meeting the increasing demand for sustainable products.