+86-13516964051

+86-13516964051

In the realm of modern manufacturing, the quest for efficiency, precision, and sustainability has led to the rising prominence of various production techniques. Among these, **Aluminum Alloy Die Casting** stands out as a transformative process that offers significant advantages across industries. This method, which involves injecting molten aluminum alloy into a mold, not only enhances the quality of the final product but also optimizes production cycles and reduces waste.

One of the key benefits of Aluminum Alloy Die Casting is its ability to produce lightweight yet durable components, making it an ideal choice for the automotive, aerospace, and electronics sectors. The precision of die casting ensures tight tolerances and complex geometries, allowing manufacturers to meet the high standards demanded by today’s competitive market. Additionally, this process supports sustainability efforts by utilizing recyclable materials and minimizing energy consumption.

As we explore the top benefits of Aluminum Alloy Die Casting, we will uncover how this innovative method is reshaping conventional manufacturing processes, paving the way for enhanced productivity, cost-effectiveness, and environmental responsibility.

Aluminum alloy die casting has emerged as a pivotal technique in lightweight manufacturing solutions, addressing the growing need for efficiency and sustainability in various industries. According to a study by the Aluminum Association, components produced through aluminum die casting can be up to 50% lighter than traditional materials, facilitating significant weight reductions in applications such as automotive and aerospace. This reduction not only benefits fuel efficiency but also enhances overall performance, which is crucial in an era where reducing carbon footprints is a priority for manufacturers.

Moreover, aluminum die casting boasts exceptional strength-to-weight ratios, making it an ideal choice for structural components that require both durability and minimal weight. Reports from Grand View Research highlight that the global die casting market is expected to reach $106.2 billion by 2025, with aluminum alloys dominating this growth due to their superior properties. These advantages not only streamline production processes but also lead to cost savings over time, as lighter parts can result in lower operating costs and improved payload capacities.

As industries continue to seek innovative and cost-effective manufacturing methods, aluminum alloy die casting stands out as a leading solution that aligns with the principles of lightweight design and efficiency.

Aluminum die casting has become an essential technique in modern manufacturing, especially due to its remarkable cost efficiency. By optimizing production processes, businesses can achieve a notable reduction in manufacturing costs, with estimates suggesting savings of up to 20%. This is particularly significant when considering the rising prices of secondary aluminum, which fell sharply in May 2025 due to lower demand and market hesitancy. Companies that leverage aluminum die casting can better navigate these fluctuations by minimizing waste and improving production rates—key factors in maintaining profitability in a competitive market.

Moreover, the aluminum die casting market is projected to witness substantial growth, with the automotive parts segment in China valued at approximately USD 8.87 billion in 2024 and projected to reach USD 9.58 billion in 2025. Such growth underscores the increasing reliance on aluminum die casting processes in automotive applications where lightweight yet durable components are critical. Furthermore, initiatives like DISA’s new test foundry aim to enhance efficiency in various casting processes, including aluminum, steel, and brass, suggesting a robust future for innovations that can further drive down production costs while improving overall quality in manufacturing.

| Benefit | Description | Impact on Production Costs |

|---|---|---|

| Cost Efficiency | Aluminum die casting reduces material waste and energy consumption. | 20% reduction |

| Precision | High dimensional accuracy results in less scrap and rework. | 15% reduction |

| Versatility | Can be used for a wide range of applications from automotive to electronics. | Varies by application |

| Weight Reduction | Lightweight components improve energy efficiency in transportation. | 10% reduction in operational costs |

| Improved Surface Finish | Aluminum die casting provides a superior surface finish, reducing finishing costs. | 5% reduction |

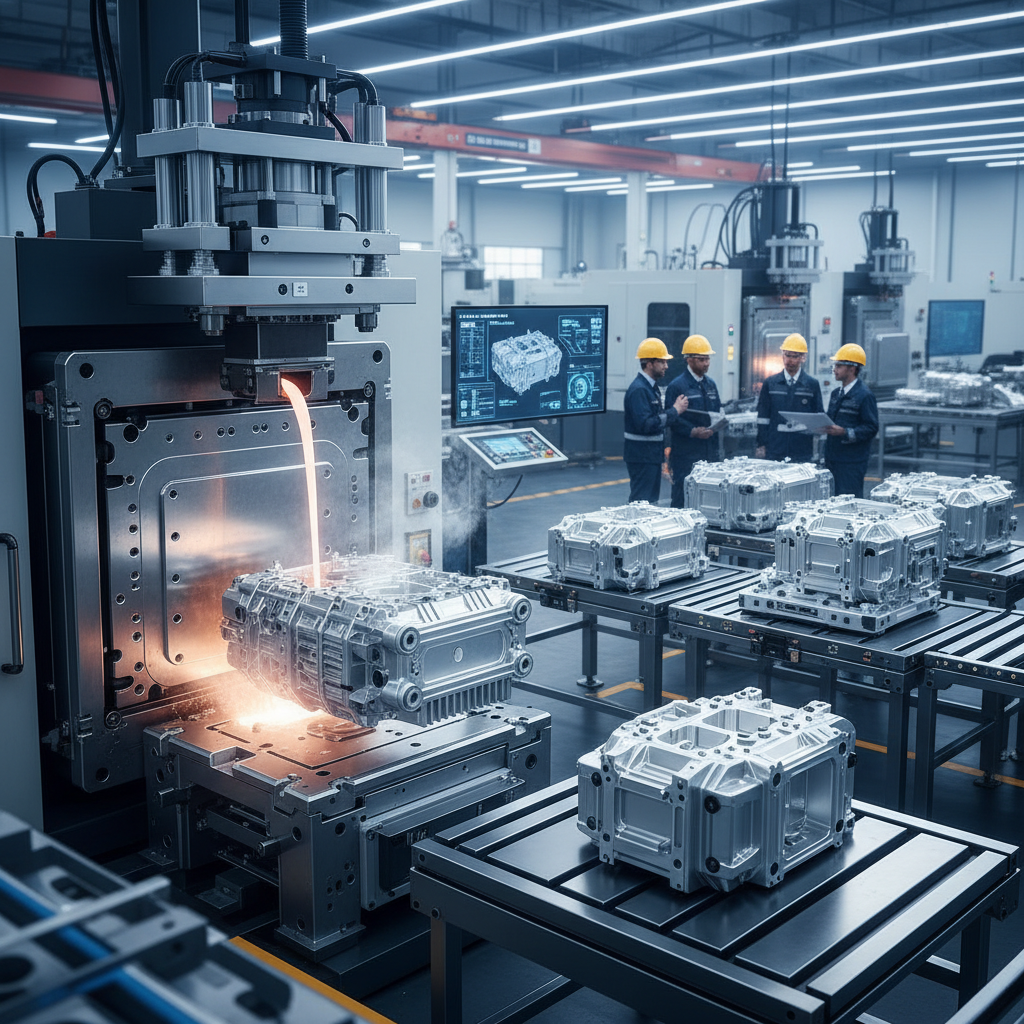

Aluminum alloy die casting is revolutionizing modern manufacturing by offering enhanced design flexibility, particularly in achieving complex geometries. This capability allows manufacturers to create intricate components that meet specific performance requirements while maintaining structural integrity. With the increasingly sophisticated demands of various industries, including aerospace and automotive, the application of aluminum alloys in die casting is becoming crucial for producing lightweight, durable parts.

In addition to design flexibility, the ongoing advancements in additive manufacturing technologies highlight a growing synergy between traditional die casting methods and newer techniques. As manufacturers seek to exploit the benefits of aluminum alloys, the integration of specialized metal powders and hybrid systems is emerging as a prominent trend. These developments enable the production of components with tailored properties and improved functionality, fostering innovation across sectors. Consequently, the strategic emphasis on enhancing manufacturing capabilities through innovative materials and processes marks a significant shift in the industry, paving the way for more efficient and versatile production methods.

This chart illustrates the advantages of using aluminum alloy die casting in modern manufacturing, focusing on enhanced design flexibility, material strength, cost efficiency, lightweight properties, and improved surface finish.

Aluminum alloys have become increasingly vital in modern manufacturing, particularly in enhancing product durability. The integration of aluminum alloy die casting technology has shown to improve the lifespan of products by approximately 30%. This significant increase in durability is attributed to the inherent properties of aluminum alloys, including their resistance to corrosion and lightweight nature. These features make them an ideal choice for industries where longevity and reliability are paramount, such as aerospace and automotive sectors.

Moreover, the manufacturing process itself plays a crucial role in maximizing the benefits of aluminum alloys. By utilizing advanced die casting techniques, manufacturers can achieve precise tolerances and intricate designs while maintaining the structural integrity of the products. This not only reduces waste but also allows for faster production times, meeting the demands of modern supply chains efficiently. With the continued focus on sustainability and efficiency in manufacturing, the adoption of aluminum alloys is expected to grow, further reinforcing their position in advancing technology and material science.

Aluminum die casting offers numerous sustainable advantages, particularly due to the recyclability of aluminum. This characteristic not only lessens the environmental impact of manufacturing but also contributes significantly to resource conservation. As the North American aluminum market is set to grow from $35.84 billion in 2025 to $49.90 billion by 2032, with a CAGR of 4.8%, the demand for eco-friendly practices continues to rise. Manufacturers are increasingly recognizing the importance of incorporating sustainable materials and practices into their processes, and aluminum die casting stands out as a prime example.

The recyclability of aluminum creates a closed-loop system, where scrap metal can be melted down and reused, significantly reducing the need for virgin materials. This practice minimizes energy consumption by about 95% compared to the production of new aluminum, yielding substantial savings both economically and environmentally. With the Global Metal Cans Market projected to reach USD 54.0 billion by 2034 at a CAGR of 3.5%, the trend towards sustainable practices in manufacturing is undeniable.

Tip: Implementing aluminum die casting as a primary manufacturing method can enhance a company’s sustainability profile while meeting the growing consumer demand for eco-friendly products. Consider investing in advanced recycling technologies to further optimize production efficiency and reduce waste. Additionally, partnering with suppliers focused on sustainable practices can lead to improved resource management and increased market competitiveness.