+86-13516964051

+86-13516964051

In the world of manufacturing, Aluminum Parts have emerged as a pivotal component across various industries, thanks to their lightweight yet durable characteristics. As John Smith, an industry expert with over two decades of experience in metallurgical engineering, wisely stated, "The versatility and strength of aluminum allow for innovative designs that traditional materials simply cannot achieve." This statement encapsulates the essence of why Aluminum Parts are not only favored but also widely used in applications ranging from automotive production to aerospace engineering.

The significance of Aluminum Parts lies not only in their material properties but also in the numerous benefits they offer. They are resistant to corrosion, have excellent thermal and electrical conductivity, and are recyclable, which aligns with the growing demand for sustainable manufacturing practices. As industries continue to evolve and embrace advanced technologies, the role of Aluminum Parts becomes increasingly critical, providing solutions that enhance efficiency and reduce environmental impact.

As we delve deeper into the topic of Aluminum Parts, we will explore their key benefits and diverse applications, shedding light on how they are transforming industries and shaping the future of manufacturing. Understanding these elements is essential for anyone looking to leverage the advantages of this remarkable material in their projects.

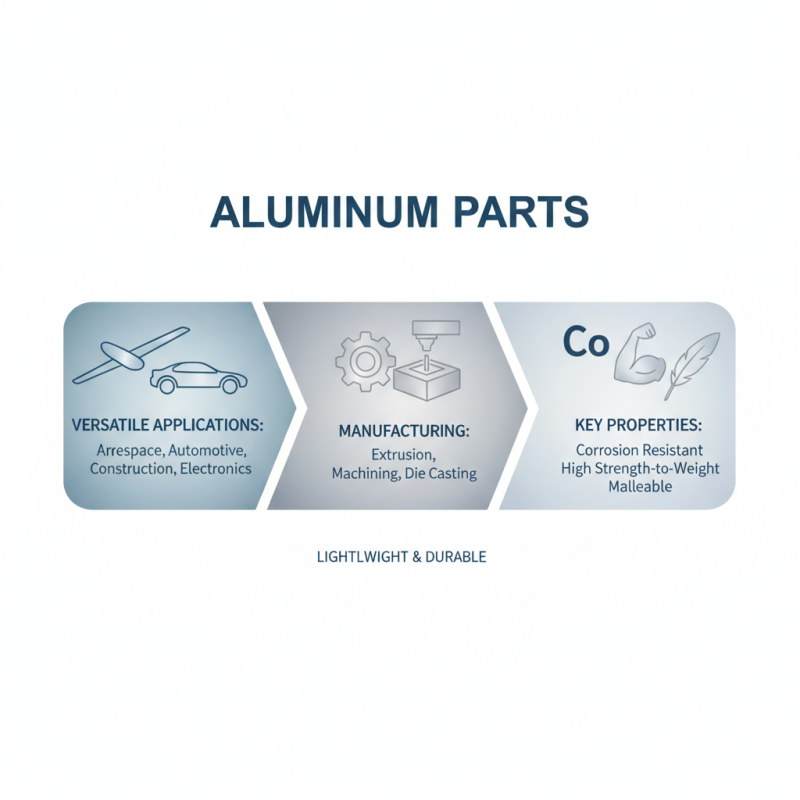

Aluminum parts are components made from aluminum, a lightweight and versatile metal known for its excellent properties such as corrosion resistance, high strength-to-weight ratio, and malleability. This makes aluminum an ideal choice for a wide range of applications, from aerospace and automotive industries to construction and consumer electronics. The manufacturing process can involve various methods like extrusion, machining, and die casting, allowing for the creation of intricate designs that meet specific engineering requirements.

One of the key attributes of aluminum parts is their ability to be anodized, which enhances their durability and aesthetic appeal. This anodization process creates a protective layer that not only prevents oxidation but also provides a surface that can be customized in color and texture. Additionally, aluminum's conductive properties make it suitable for electrical applications, while its recyclability contributes to sustainable practices in manufacturing. As industries continue to seek solutions that balance performance with environmental responsibility, aluminum parts remain a reliable choice for modern engineering challenges.

Aluminum parts are widely used in various industries due to their remarkable properties. One of the key benefits of aluminum parts is their lightweight nature, which makes them an ideal choice for applications where weight reduction is paramount, such as in the automotive and aerospace sectors. This lightweight characteristic not only enhances fuel efficiency but also contributes to improved performance and handling.

Another significant advantage of aluminum parts is their excellent resistance to corrosion. This property is particularly beneficial in environments where exposure to moisture and chemicals is common. The natural oxide layer that forms on aluminum surfaces protects it from further degradation, making it a reliable option for outdoor applications, marine environments, and chemical processing industries.

Tips: When considering aluminum parts for your project, it’s important to assess the specific requirements of your application. Conduct thorough tests to evaluate their performance under different conditions, and always consult with experts to select the right aluminum alloy for your needs. Additionally, utilizing proper finishing techniques can enhance the aesthetics and durability of aluminum components.

| Description | Key Benefits | Applications |

|---|---|---|

| Aluminum Extrusions | Lightweight, customizable shapes, high strength-to-weight ratio | Construction, automotive parts, frames, and supports |

| Aluminum Castings | Complex shapes, excellent surface finish, good wear resistance | Machinery, engine components, and automotive parts |

| Aluminum Sheets | Corrosion resistance, easy to fabricate, good aesthetics | Packaging, signage, and consumer goods |

| Aluminum Forgings | High strength, improved structural integrity, and toughness | Aerospace, automotive, and heavy machinery |

| Aluminum Alloys | Enhanced properties for specific applications, lightweight | Various industries including electronics, automotive, and aerospace |

Aluminum parts are increasingly utilized across various industries due to their unique combination of lightweight properties, high strength, and excellent corrosion resistance. Common applications of aluminum parts can be found in automotive, aerospace, construction, and electronics sectors. For instance, in the automotive industry, approximately 200 million pounds of aluminum are used annually in vehicle manufacturing, accounting for about 40% of the total body structure of modern vehicles. This significant use reflects the material's ability to improve fuel efficiency and reduce emissions, aligning with global sustainability goals.

In aerospace, aluminum components contribute to reducing weight while maintaining structural integrity, which is crucial for enhancing aircraft performance and fuel efficiency. Reports indicate that the demand for aluminum in aerospace is projected to grow at a CAGR of 3.5% over the next five years, showcasing its essential role in aviation technology. Meanwhile, in the construction sector, aluminum is favored for window frames, roofing, and facades because of its durability and low maintenance requirements. The global construction industry is expected to consume around 30 million metric tons of aluminum by 2025.

In aerospace, aluminum components contribute to reducing weight while maintaining structural integrity, which is crucial for enhancing aircraft performance and fuel efficiency. Reports indicate that the demand for aluminum in aerospace is projected to grow at a CAGR of 3.5% over the next five years, showcasing its essential role in aviation technology. Meanwhile, in the construction sector, aluminum is favored for window frames, roofing, and facades because of its durability and low maintenance requirements. The global construction industry is expected to consume around 30 million metric tons of aluminum by 2025.

Tips: When considering the use of aluminum parts, it's essential to evaluate the specific demands of your application. Look for factors such as weight reduction opportunities, corrosion resistance needs, and overall lifecycle costs to make informed decisions. Additionally, establishing strong supplier relationships can ensure access to high-quality materials tailored to your project requirements.

Aluminum parts are integral components in various industries, thanks to their lightweight nature, corrosion resistance, and excellent machinability. The manufacturing processes for aluminum parts are vital in determining the quality and performance of the final products. Key methods include extrusion, die casting, and machining, each offering unique benefits suited for specific applications.

Extrusion is one of the most common techniques used in the production of aluminum parts, particularly for creating long, continuous shapes with uniform cross-sections. According to a report by the Aluminum Association, the extrusion process accounts for approximately 28% of the total aluminum production in the United States. This method not only allows for complex geometries but also has a high throughput, making it cost-effective for high-volume production runs. Additionally, die casting is another essential technique that offers high precision and excellent surface finishes, particularly useful for complex shapes and intricate designs.

Machining, on the other hand, involves cutting, drilling, or milling aluminum to achieve desired dimensions and finishes. As per the findings from the International Journal of Advanced Manufacturing Technology, the machining of aluminum parts is projected to grow by 5.2% annually, driven by increasing demand in aerospace and automotive sectors. Each manufacturing process for aluminum parts contributes to the versatility and functionality of aluminum, making it a preferred choice for manufacturers looking to balance performance and efficiency.

When comparing aluminum to other materials such as steel, plastic, and titanium, several key factors emerge that highlight aluminum's unique advantages. Aluminum is significantly lighter than steel and titanium, which makes it an excellent choice for applications where weight is a critical factor, such as in the aerospace and automotive industries. This reduced weight can contribute to improved fuel efficiency in vehicles and lower transportation costs in various applications. Furthermore, aluminum boasts a high strength-to-weight ratio, allowing for the production of components that are both strong and lightweight.

In addition to its weight advantages, aluminum also exhibits excellent corrosion resistance, particularly when naturally oxidized. This attribute sets it apart from steel, which can rust without proper treatment. The longevity and durability of aluminum components make them ideal for use in environments exposed to moisture and harsh weather conditions. Furthermore, aluminum's malleability allows for complex shapes and designs that are often difficult to achieve with other materials. While plastics may be lighter and less expensive, they generally lack the strength and thermal resistance that aluminum provides. As a result, industries that prioritize lightweight, durable, and corrosion-resistant materials often favor aluminum over its counterparts.