+86-13516964051

+86-13516964051

In the realm of modern manufacturing, efficiency and adaptability are paramount, with industries consistently seeking innovative methods to enhance production processes. One such transformative technique is Aluminum Alloy Die Casting, which has emerged as a frontrunner in delivering superior mechanical properties and intricate designs at competitive costs. According to a recent report by MarketsandMarkets, the global die casting market size is projected to reach $82.8 billion by 2027, underscoring the growing reliance on this manufacturing method across various sectors, including automotive and aerospace.

Aluminum Alloy Die Casting not only offers outstanding weight-to-strength ratios but also promotes faster turnaround times, reducing the time to market for new products. The lightweight nature of aluminum in combination with its excellent thermal and electrical conductivity positions it as an ideal choice for industries aiming to optimize their product performance while minimizing energy consumption. A study conducted by the Aluminum Association indicates that using aluminum in automotive applications can result in a reduction of over 30% in vehicle weight, further enhancing fuel efficiency.

As manufacturers continue to innovate and embrace sustainable practices, Aluminum Alloy Die Casting stands out for its recyclability and minimal waste generation. The ability to produce complex shapes with precise tolerances makes it a vital manufacturing process for the future, ensuring that industries can meet the evolving demands of consumers while adhering to stringent environmental standards.

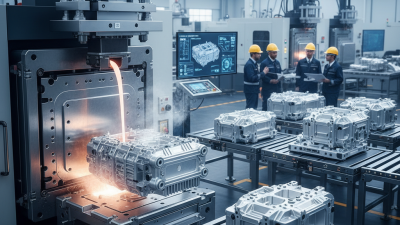

Aluminum alloy die casting has become a critical process in modern manufacturing, particularly within the automotive industry, where the demand for lightweight materials can significantly impact fuel efficiency and emissions. Reports indicate that using aluminum alloys can reduce the weight of components by up to 30% compared to traditional materials, leading to better performance in electric vehicles (EVs). As the industry shifts towards electrification, the combination of aluminum's strength and lightweight properties makes it an ideal choice for manufacturing structural components, battery enclosures, and other critical parts.

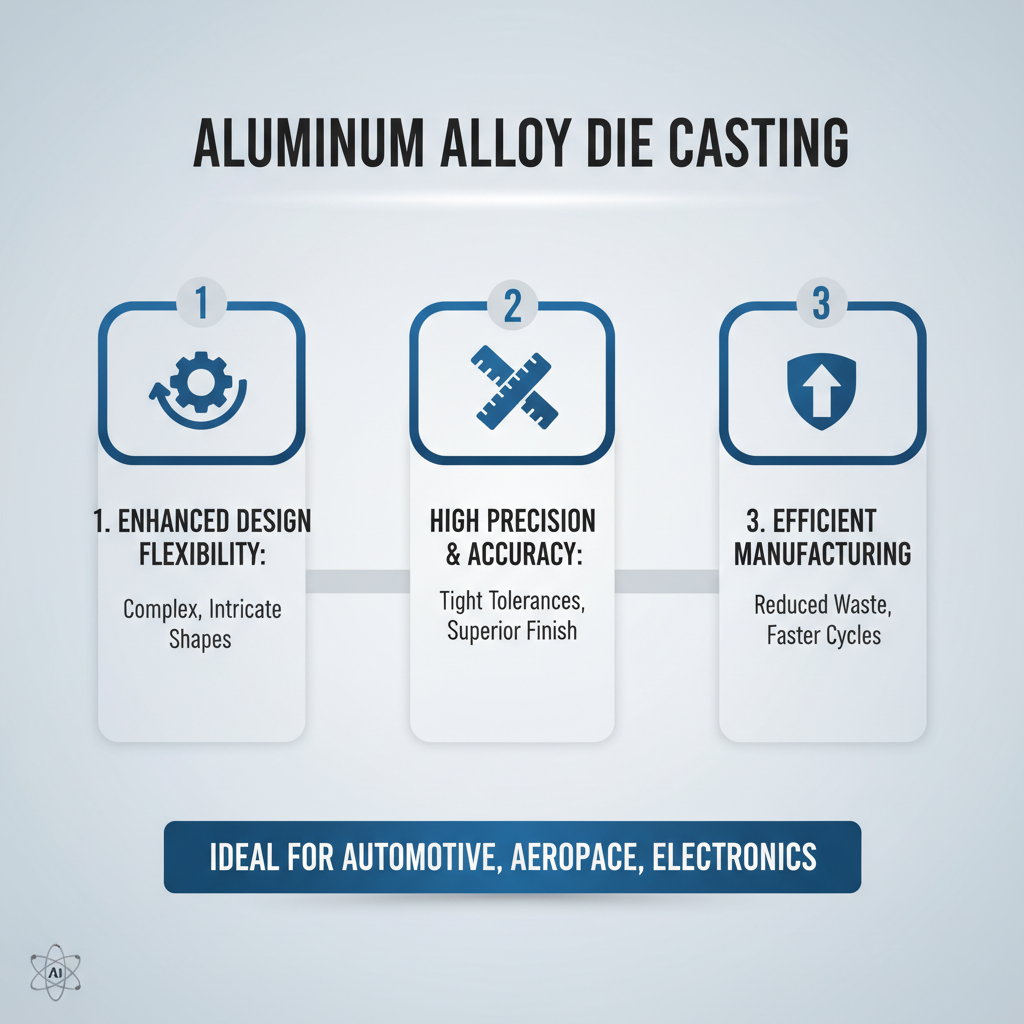

In comparison to other casting processes, high-pressure die casting (HPDC) stands out for its ability to produce complex shapes with excellent dimensional accuracy. This process not only enhances production efficiency but also reduces material waste, making it a sustainable choice for manufacturers. According to industry data, the global aluminum die casting market is projected to grow at a CAGR of over 5% from 2023 to 2028, underscoring its vital role in modern manufacturing practices. The hybrid production process that integrates HPDC with additive manufacturing further exemplifies innovation in creating lightweight and cost-effective solutions, setting a new standard for production in the automotive sector.

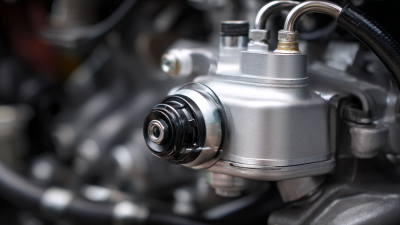

Aluminum alloy die casting has become a preferred choice in modern manufacturing due to its remarkable durability and strength. The unique properties of aluminum alloys enhance component performance under various conditions, making them ideal for industries ranging from automotive to aerospace. These alloys boast a high strength-to-weight ratio, which allows manufacturers to produce lightweight components that do not compromise on structural integrity. As a result, products made from aluminum alloys can withstand significant stress and impacts, ensuring longevity and reliability.

Tips: When considering aluminum alloy die casting for your projects, ensure you select the right alloy formulation that suits your specific application demands. You may also want to work closely with experienced manufacturers who can optimize the casting process to enhance the strength and durability of your components. Regular testing and quality assurance protocols can further improve the performance of your aluminum parts over their lifecycle.

The versatility of aluminum alloys offers the added benefit of corrosion resistance, enabling components to maintain their aesthetics and functionality over time, even in harsh environments. This protection is essential for applications where exposure to moisture and chemicals is a concern. By leveraging these advantages, manufacturers can deliver products that not only meet industry standards but also exceed customer expectations for quality and performance.

| Benefit | Description | Impact on Manufacturing |

|---|---|---|

| High Strength-to-Weight Ratio | Aluminum alloys offer excellent strength while remaining lightweight. | Reduces material costs and improves efficiency in shipping and handling. |

| Corrosion Resistance | Aluminum naturally forms a protective oxide layer. | Increases the lifespan of components, reducing the need for replacements. |

| Complex Geometries | Die casting allows for intricate designs without additional tooling. | Enhances product design flexibility and reduces assembly time. |

| Rapid Production | High efficiency in mass production of die-cast parts. | Speeds up time-to-market for products. |

| Recyclability | Aluminum can be recycled without degrading its properties. | Promotes sustainability and reduces raw material costs. |

Aluminum alloy die casting processes offer significant cost advantages for manufacturers, especially in industries that prioritize efficiency and scalability. The inherent properties of aluminum alloys, such as their lightweight yet strong nature, play a crucial role in reducing material costs and enhancing product performance. This is particularly beneficial in the automotive sector, where shifting towards lighter materials is essential for improving fuel efficiency and meeting strict emissions regulations.

Moreover, the automated nature of die casting allows for high-volume production with minimal waste, further driving down costs. This process not only ensures uniformity in product quality but also shortens manufacturing cycles, making it a preferred choice for many manufacturers looking to optimize productivity. As the demand for cost-effective and efficient manufacturing solutions continues to rise, the aluminum alloy die casting process stands out as a reliable method to meet these challenges while maintaining competitive pricing.

Aluminum alloy die casting offers improved design flexibility and precision in manufacturing, making it an invaluable process for industries seeking efficient production methods. With the ability to create intricate designs with high dimensional accuracy, manufacturers can produce complex components that meet stringent performance specifications. This versatility allows for innovative product development, enabling companies to stay competitive in rapidly evolving markets.

Tips for maximizing design flexibility include early collaboration between design and manufacturing teams. Engaging engineers during the initial stages can help identify potential design challenges and optimize the casting process, ultimately saving time and reducing costs. Additionally, leveraging simulation tools can help predict performance outcomes and refine designs before physical prototypes are created.

As the market for specialized metal powders grows, particularly in additive manufacturing, businesses should consider the integration of aluminum alloys in their design processes. These materials not only enhance strength-to-weight ratios but also support more sustainable manufacturing practices. By investing in advanced materials and techniques, manufacturers can achieve greater efficiency while delivering high-quality products that cater to diverse applications.

Aluminum alloys, widely used in die casting, offer significant environmental sustainability advantages that are crucial for modern manufacturing practices. One of the key benefits is their lightweight nature, which contributes to energy efficiency in product transportation and usage. Reduced weight translates to lower fuel consumption in vehicles and machinery, thereby decreasing greenhouse gas emissions. As industries increasingly focus on eco-friendly practices, the adoption of aluminum alloys aligns with these sustainability goals.

Moreover, aluminum alloys are highly recyclable, which further enhances their environmental benefits. The recycling process requires only a fraction of the energy needed to produce new aluminum, significantly reducing the carbon footprint associated with manufacturing. This not only conserves natural resources but also minimizes waste, as recycled aluminum can be repurposed repeatedly without loss of quality. By choosing aluminum alloy die casting, manufacturers can significantly contribute to a circular economy, wherein materials are reused and repurposed, fostering a more sustainable approach to production and consumption.