+86-13516964051

+86-13516964051

Application of aluminum alloy high pressure casting in the field of intelligent robots

description1

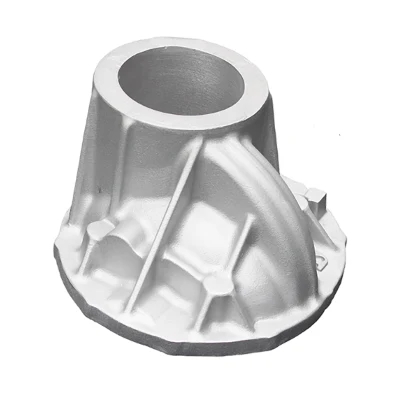

Precision joint housing of intelligent robots

The joints of intelligent robots, like the joints of the human body, have extremely high requirements for materials with both flexibility and bearing capacity. The aluminum alloy high-pressure casting process enables the joint housing to accurately fill the aluminum alloy liquid into every tiny corner of the complex mold during the molding process. For example, the wrist joint housing of a six-axis industrial robot has a wall thickness of only 3-5mm, but can bear a torque of 50-100N・m, thanks to the dense organizational structure given by high-pressure casting. In production, we precisely control the temperature at 660±5℃ to make the aluminum alloy fit tightly with the mold under a high pressure of 100-150MPa, ensuring that the dimensional accuracy of the housing reaches ±0.1mm and the surface roughness Ra is controlled within 1.6μm, laying the foundation for high-precision assembly and smooth operation of joint components.

Reducer housing

As the core transmission component, the housing quality of the robot reducer directly affects the transmission efficiency and stability. The reducer housing formed by aluminum alloy high-pressure casting has excellent thermal stability and mechanical properties. Take the harmonic reducer housing as an example. Although it is small in size, it has a complex structure with fine meshing teeth and mounting holes inside. During the casting process, we use advanced mold design and optimization technology to control the deformation of the housing within 0.05mm under the alternating stress of 80-120MPa. At the same time, through a special surface treatment process, the wear resistance of the housing is enhanced, and the transmission accuracy is guaranteed during the high-frequency reciprocating motion of the robot, the maintenance cost is reduced, the service life is extended, and a reliable transmission guarantee is provided for the precise movement of the intelligent robot.

Controller housing

The controller housing of the intelligent robot must not only protect the internal precision electronic components from the external environment, but also have good heat dissipation performance. The controller housing made of aluminum alloy high-pressure casting has 10-15 heat dissipation ribs evenly distributed on a length of 150-200mm through an optimized heat dissipation rib structure design, and the spacing is precisely controlled at 3-5mm. When the robot generates heat during continuous operation, the high thermal conductivity of aluminum alloy (thermal conductivity of 100-200W/(m・K)) can quickly transfer heat to the surface of the shell, and then control the temperature within the safe working range of electronic components (generally not exceeding 60℃) through the contact between the heat dissipation ribs and the air. At the same time, its good electromagnetic shielding performance effectively prevents electromagnetic interference and ensures the stable operation of the controller, which is a solid protection for the efficient "brain" of the intelligent robot.

01

FAQ

Q1: How to ensure the durability of robot parts made of aluminum alloy high-pressure casting under high-frequency use?

A1: We strictly control the source of materials and select high-quality aluminum alloys to ensure that their tensile strength can reach 250-300MPa. During the high-pressure casting process, precise process parameter control makes the internal structure of the casting dense and reduces defects such as pores and inclusions. At the same time, through the subsequent heat treatment strengthening, internal stress is eliminated and the fatigue strength of the components is further improved. In actual application, after simulation test, the robot joint shell can still maintain stable performance under 10^7 cycles of loading, meeting the needs of high-frequency use.

Q2: Can the dimensional accuracy of robot castings with complex shapes be guaranteed?

A2: Of course. We use advanced mold manufacturing technology and precision casting equipment. In the mold design stage, we use computer simulation analysis to optimize the pouring system and mold temperature field distribution. During the casting process, the aluminum alloy liquid is accurately filled into the mold cavity at high speed and high pressure through a high-precision injection device, so that the dimensional accuracy of the casting can reach IT7-IT8 level, and the dimensional deviation of key parts is controlled within ±0.05mm, which fully meets the high-precision assembly requirements of intelligent robots for complex-shaped castings.

Q3: Are robot parts cast by aluminum alloy high-pressure casting prone to corrosion?

A3: We have perfect protection measures for this. First of all, select aluminum alloy materials with less impurities to fundamentally reduce the risk of corrosion. After casting, special surface treatments such as anodizing will be performed to form a dense oxide film with a thickness of up to 10-25μm. This film has excellent corrosion resistance and can effectively resist corrosive media such as acids, alkalis and salts in industrial environments. After the salt spray test, the treated castings had no obvious corrosion on the surface in a 500-hour salt spray environment, ensuring the long-term stable operation of robot components in harsh environments.

Q4: Is the delivery cycle long for customized aluminum alloy high-pressure casting robot components?

A4: We have a mature customized production process and an efficient supply chain system. From customer requirements to mold design and manufacturing, to product trial production and mass production, each link is closely connected. For customized parts of conventional size and structure, delivery can generally be completed within 3-4 weeks; for complex and large parts, the delivery cycle is only 6-8 weeks. At the same time, we will maintain real-time communication with customers, provide timely feedback on production progress, and ensure the smooth progress of customer projects.

Q5: Is the cost of aluminum alloy high-pressure casting robot parts high?

A5: From the perspective of long-term benefits, the cost advantage is obvious. Although the cost of aluminum alloy raw materials is slightly higher than that of some engineering plastics, the high-pressure casting process can achieve near-net molding, with a material utilization rate of up to 85% - 95%, reducing subsequent processing allowances. At the same time, during mass production, the mold sharing cost is reduced, and the casting performance is stable, reducing the rework and scrap costs caused by quality problems. Compared with traditional manufacturing processes, the overall cost can be reduced by 20% - 30%, providing intelligent robot companies with cost-effective component solutions.