+86-13516964051

+86-13516964051 High-Precision Aluminum CNC Machining Parts | Reliable ODM & Factory Solutions

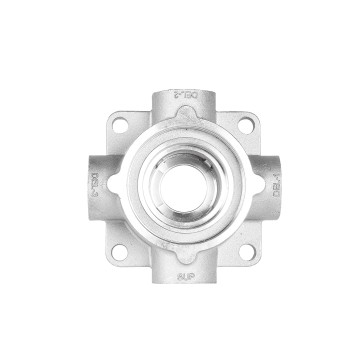

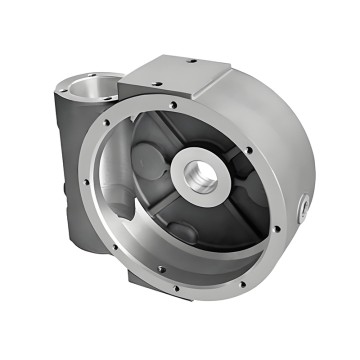

I provide exceptional Aluminum Cnc Machining Parts solutions tailored to the diverse needs of various industries. Specializing in ODM, my production process focuses on your specific requirements, guaranteeing optimal performance and precision. By collaborating with trusted factories and suppliers, I source high-quality materials to manufacture custom parts that enhance the reliability of your products. My extensive experience in machining and manufacturing enables me to deliver components that exceed expectations. At Yongkang Hantai Industry And Trade Co., Ltd., I am committed to maintaining exceptional quality standards and efficiency throughout every project phase. Together, we can bring your designs to life with precision-engineered aluminum parts that elevate your business.

Methods To Aluminum Cnc Machining Parts Where Service Meets Innovation Factory

In today's rapidly evolving manufacturing landscape, the importance of innovative solutions in aluminum CNC machining cannot be overstated. At Yongkang Hantai Industry & Trade Co., Ltd., established in 1997, we harness cutting-edge technology to produce precision components tailored for the automotive industry. Our commitment to quality improvement ensures that each part meets the highest standards, providing our global customers with products they can rely on. Our methods combine traditional machining techniques with modern innovations, allowing us to offer tailored solutions to meet the specific needs of our clients. From prototyping to full-scale production, we leverage our expertise to deliver components that enhance performance and durability. By prioritizing both service and innovation, we create lasting partnerships with our clients, helping them stay competitive in their markets. By choosing Yongkang Hantai, procurement professionals gain access to a dedicated team focused on delivering excellence in every project. Our extensive experience and commitment to technological advancement make us the ideal partner for businesses looking to excel in the automotive sector and beyond. Join us on this journey of innovation and quality, and discover the difference in machining excellence.

Methods To Aluminum CNC Machining Parts Where Service Meets Innovation Factory

| Method | Description | Applications | Advantages |

|---|---|---|---|

| CNC Milling | A process that uses rotary cutters to remove material from a workpiece. | Complex shapes, prototypes, and custom parts. | High accuracy, versatility, and a smooth finish. |

| CNC Turning | A technique used to rotate a workpiece while a cutting tool is fed into it. | Cylindrical parts and shafts. | High precision in round components and efficient material removal. |

| Laser Cutting | Utilizes a laser beam to slice through materials with high precision. | Sheet metal fabrication and intricate designs. | Clean cuts, minimal heat affected zone, and ability to cut complex shapes. |

| Waterjet Cutting | Uses a high-pressure jet of water mixed with abrasives to cut through materials. | Cutting thick materials and delicate operations. | No thermal distortion and versatility with different materials. |

| EDM (Electrical Discharge Machining) | A manufacturing process where a series of rapid electrical discharges is used to remove material. | Molds, dies, and complex geometries. | Ability to create intricate shapes and high precision on hard materials. |

Top Picks For Aluminum Cnc Machining Parts Where Service Meets Innovation Exceeds Industry Benchmarks

A

Ava Williams

This product is everything I hoped for and more! Customer service was quick to respond and very knowledgeable—simply fantastic!

22 June 2025

A

Alexander Young

What a fantastic product! I was pleasantly surprised by how knowledgeable and friendly the customer service team was.

07 June 2025

S

Stella Rodriguez

Absolutely love this product! Support staff were quick and professional, addressing all my concerns impressively.

30 June 2025

K

Katie Sanchez

The quality of this item is excellent! I was impressed with the dedicated and professional customer service staff.

27 June 2025

L

Lucas Young

Quality is impressive! Their customer service team was quick and knowledgeable, making my purchase a pleasure.

22 May 2025

B

Brandon Cooper

The quality stands out! The after-sales support team was quick, helpful, and clearly knowledgeable.

15 May 2025