+86-13516964051

+86-13516964051

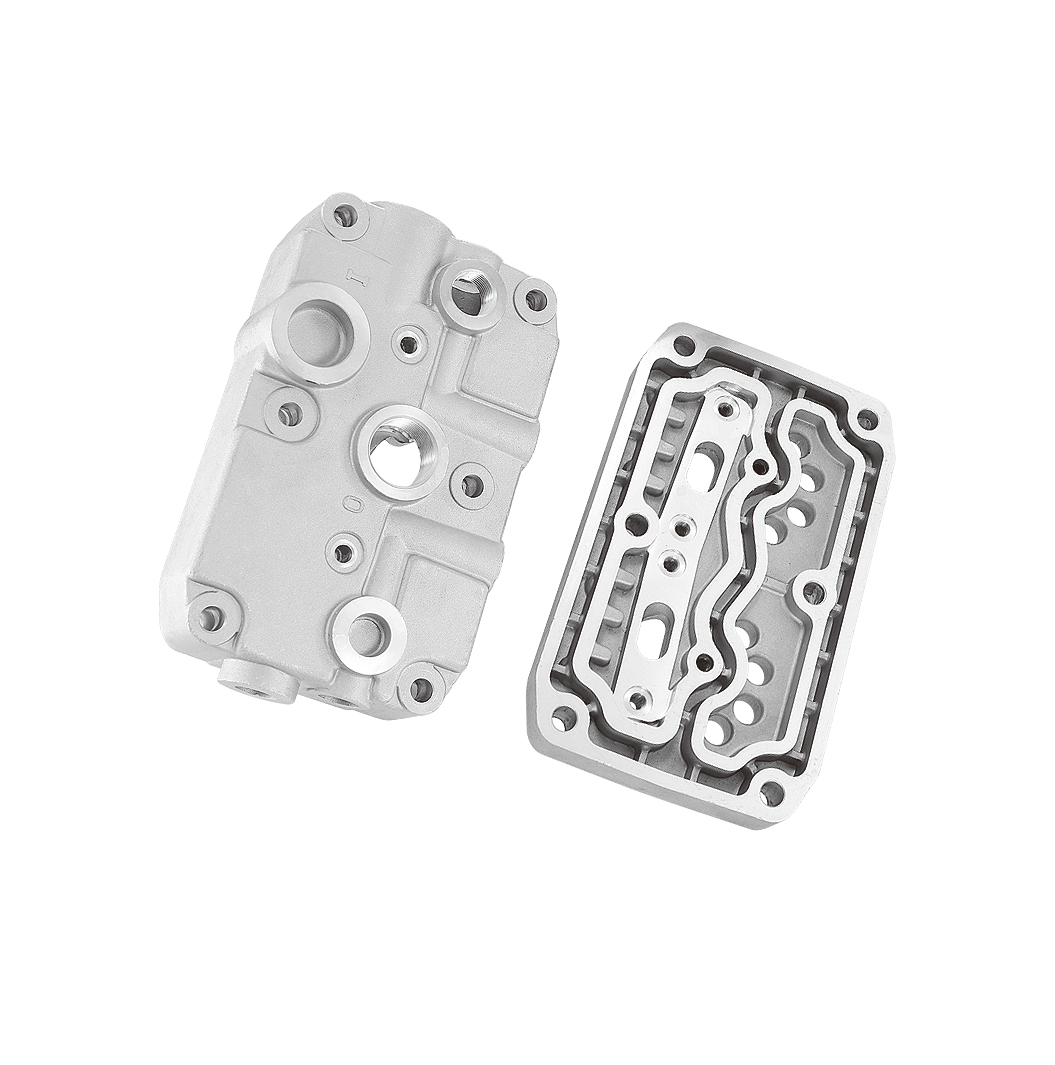

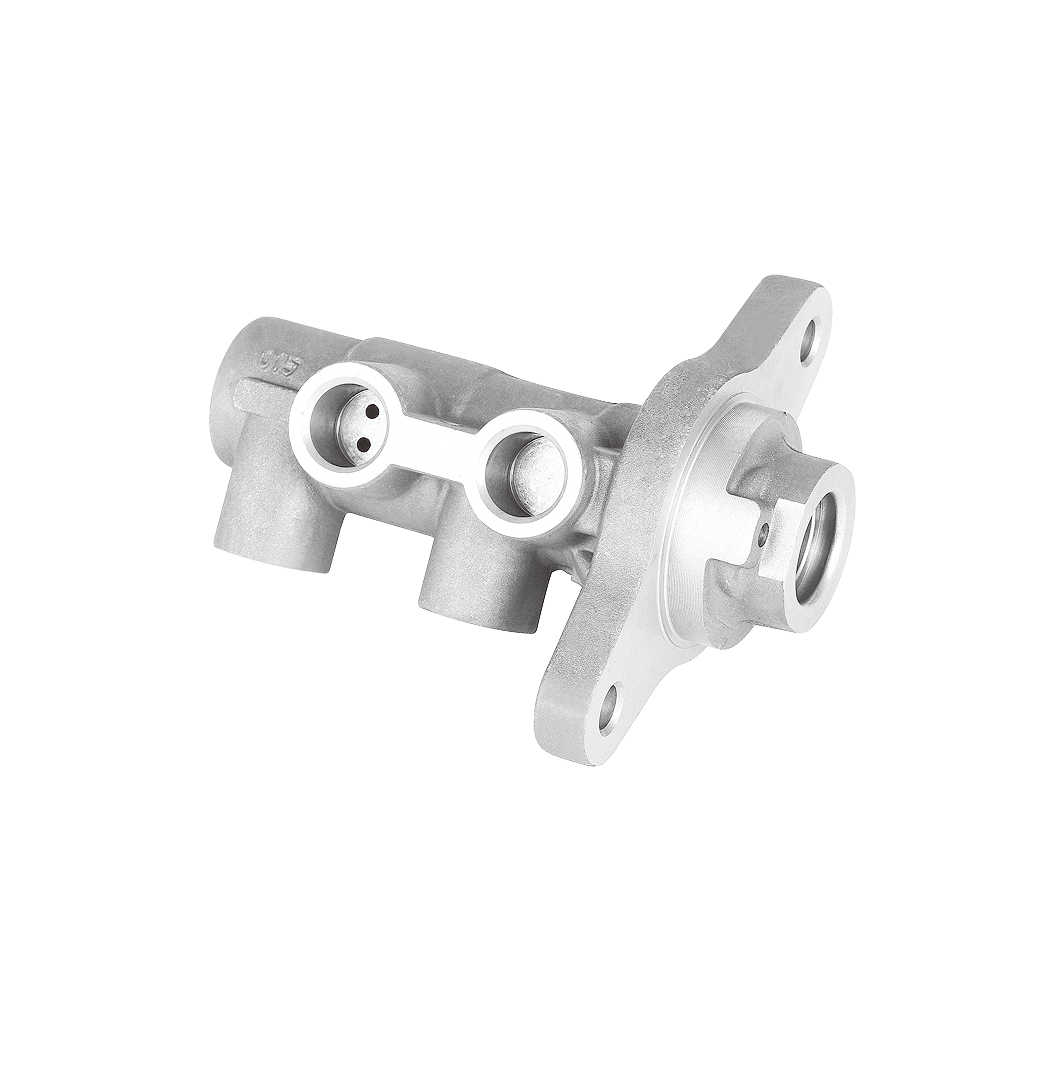

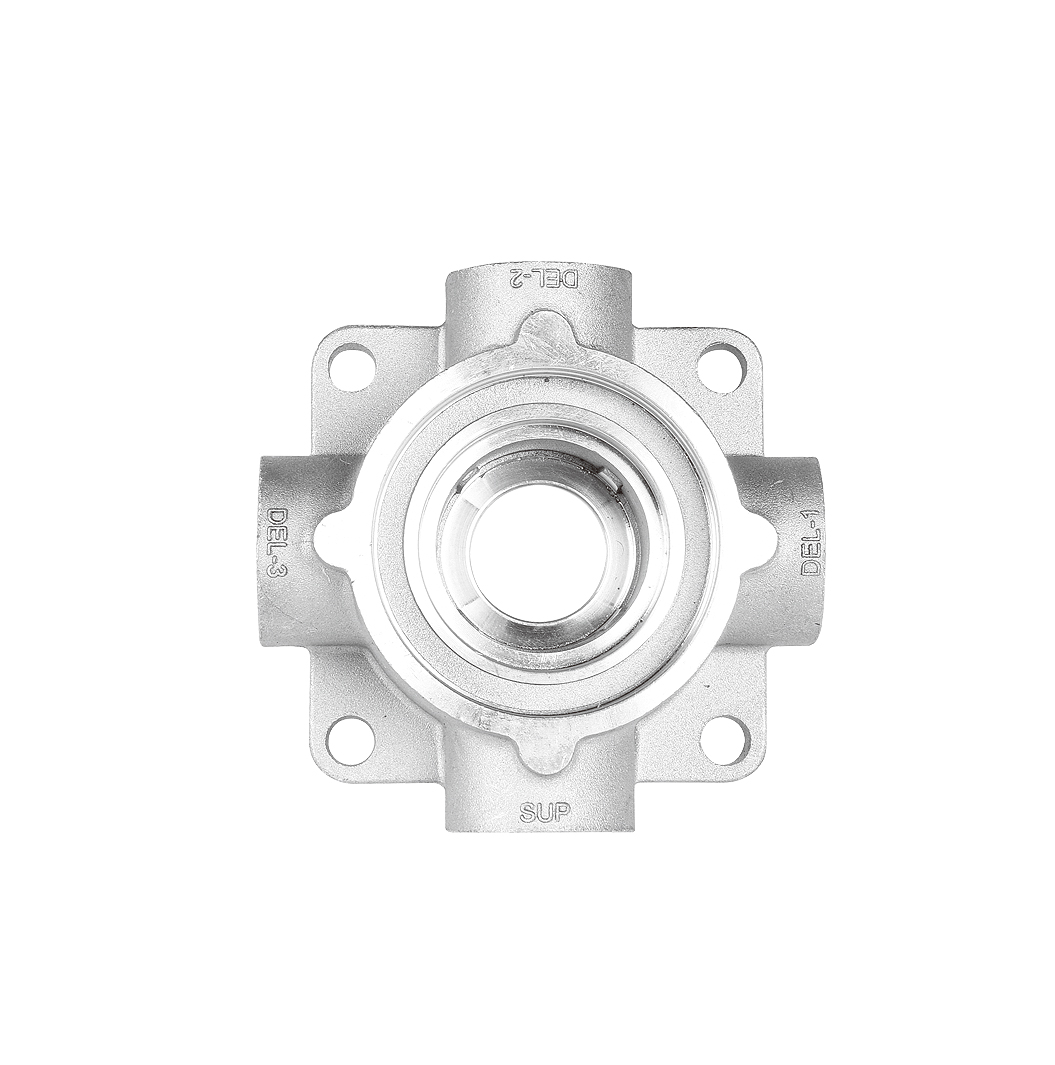

Aluminum alloy gravity casting

description1

01

advantage

1. The mold is metal type. can be repeated production of aluminum castings.

2. By assembling multiple sand cores in the mold. aluminum castings with complex shapes can be produced.

3. The size of the casting is good consistency. high dimensional accuracy.

4. liquid aluminum is poured into the metal mold at a very low speed. so a well-designed mold can produce high-quality aluminum castings without sand holes; Especially with the flip casting process. it is not easy to produce pores.

5. Because the aluminum castings produced have no pores inside. the aluminum castings can be strengthened by heat treatment. usually using the T6 heat treatment process to achieve good tensile strength and elongation.

02

Specific steps

Aluminum alloy melting: Select the appropriate aluminum alloy material (such as aluminum-silicon alloy, aluminum-copper alloy, aluminum-zinc alloy, etc.), and heat it to the melting state (usually above 660℃)

Injection mold: Pour the molten aluminum alloy liquid into the pre-designed mold. Due to the action of gravity, the liquid of aluminum alloy naturally flows into the cavity of the mold

Cooling and solidification: The molten aluminum alloy begins to cool and gradually solidify in the mold. The cooling rate, the material of the mold and the composition of the aluminum alloy will affect the structure and performance of the casting

Take out the casting: When the aluminum alloy is completely solidified, remove the casting from the mold. This process requires careful handling to avoid damage to the casting

Post treatment: The casting may require further processing, such as removal of sprue, flash, burr, grinding, polishing, or heat treatment to improve strength and hardness. Some castings also need surface coating treatment, such as spraying, anodizing, sandblasting, etc., to improve appearance and corrosion resistance .