+86-13516964051

+86-13516964051 High-Quality Aluminum Die Casting Process by Top Manufacturers in the Industry

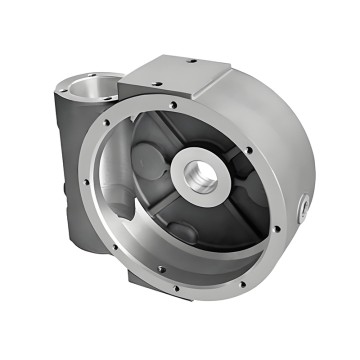

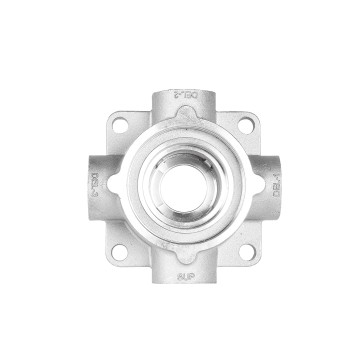

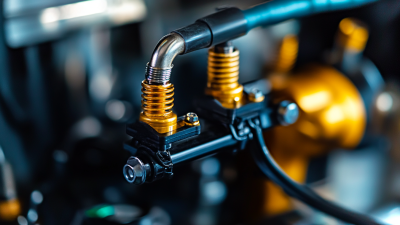

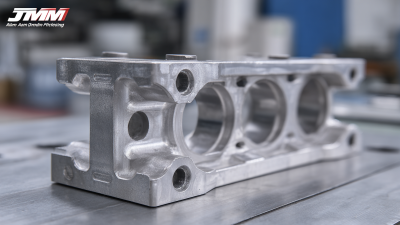

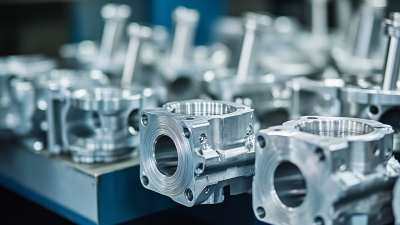

For your aluminium die casting needs, our ODM service excels in delivering quality and precision. We specialize in the Die Casting Process, guaranteeing durability in every product. With extensive manufacturing experience, we cater to multiple industries by providing customized solutions tailored to your specific requirements. Our commitment to quality ensures stringent control throughout the production phases, and our team collaborates closely with you from the initial design to the final product, whether you need prototypes or large-scale runs. Choosing our service means partnering with a dedicated team that values efficiency and effectiveness in manufacturing. Let’s turn your ideas into reality with superior aluminium die casting solutions!

Step-by-Step Guide To Aluminium Die Casting Process More Than a Supplier - A Partner Stands Out

At Yongkang Hantai Industry & Trade Co., Ltd., we understand that the aluminium die casting process is not merely a manufacturing technique; it’s a strategic partnership that drives innovation and quality in the automotive industry. Established in 1997, our company has consistently focused on technological advancements and quality improvements, positioning us as a reliable ally in the supply chain rather than just another supplier. In the aluminium die casting process, we utilize state-of-the-art technology to create Precision Parts that meet the stringent standards of our clients. Our commitment to quality is reflected in our rigorous testing and quality assurance protocols, ensuring that each component not only meets but exceeds expectations. As a partner, we collaborate closely with our clients to understand their specific needs, enabling us to deliver customized solutions that enhance their product efficiency and reliability. By choosing Yongkang Hantai as your partner, you’re not just sourcing parts; you're investing in a relationship that prioritizes your success. With decades of experience, a focus on continuous improvement, and a dedication to excellence in every project, we are here to help you navigate the complexities of the automotive supply chain and drive your business forward. Let's redefine the potential of aluminium die casting together!

Step-by-Step Guide To Aluminium Die Casting Process More Than a Supplier - A Partner Stands Out

| Step | Description | Key Considerations | Outcome |

|---|---|---|---|

| 1 | Design Phase | Ensure robustness and manufacturability of the design | Optimized design for casting |

| 2 | Tooling Creation | High-quality molds that reflect the design accurately | Durable and precise molds |

| 3 | Material Selection | Select appropriate aluminum alloy based on application | Material properties aligned with end-use |

| 4 | Die Casting Process | Melt aluminum and inject into the mold under pressure | High precision components |

| 5 | Cooling and Solidification | Allow component to cool and solidify in the mold | Ensured dimensional stability |

| 6 | Ejection and Finishing | Remove the cast component and perform finishing processes | Ready-to-use components with high surface quality |

| 7 | Quality Control | Conduct inspections and tests to ensure compliance | High-quality, reliable end products |

China Top Aluminium Die Casting Process Industry Giant From Concept to Delivery

L

Lucas Wilson

Great quality product! The customer service team was very professional, providing all the information I needed. Highly recommend!

29 June 2025

M

Madison Hall

Superb quality! The after-sales support was highly responsive and knowledgeable, making for a great buying experience.

17 May 2025

L

Layla Lee

Incredible product quality! The support showed great professionalism, ensuring all my questions were answered.

23 June 2025

G

Gavin Adams

This product is fantastic in quality! I appreciated how professional and patient the customer service staff were.

24 May 2025

B

Brielle James

This product is a game changer! Their support staff showcased professionalism and expertise, making my experience very smooth.

09 May 2025

G

Grayson White

The quality is impeccable! The professionalism and expertise of the after-sales support team were very helpful.

02 July 2025